Robot Type 1 45 cm - belt gear - direct drive - R0

-

#6 Tools, Hole Processing

-

7/11 Rotation Plates

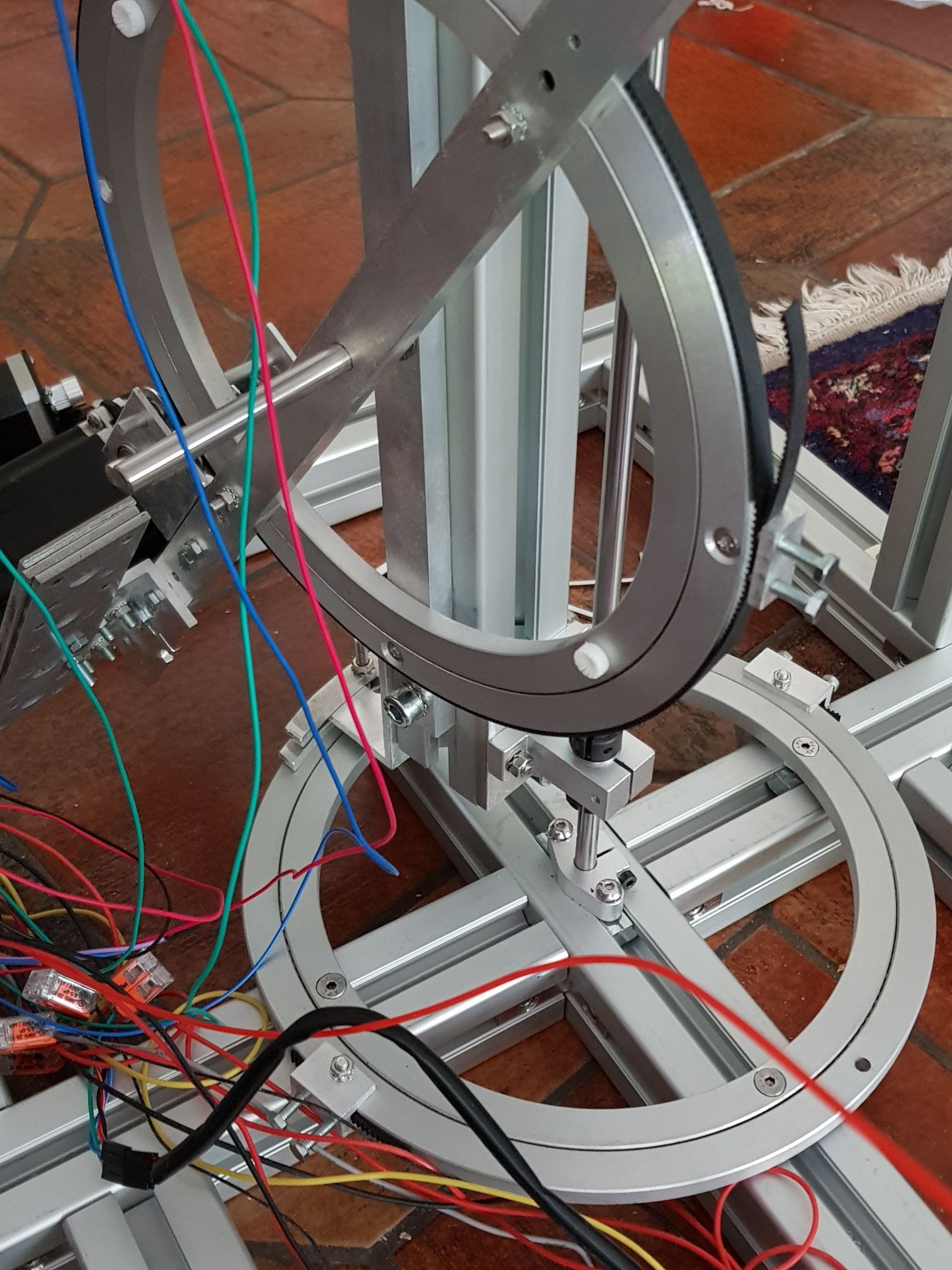

Rotation plates are big ball bearings from aluminium material with steel balls.

Plate for Axis 1 has 250 mm diameter, Axis 2 250 mm also, Axis 3 and 4 120 mm each. Weight of 250 mm is 450 g, of 120 mm is 180 g each.As example plate for Axis 4:

Building:

- connecting two arms each by 8 mm shaft, connecting to arm by 16 mm hole and F688 ball bearing

- pressing inner and outer ring of plate by spring in middle on shaft

- arms connected to plate at two holes in plate each, countersink screws

- Axis 4 special connection of arm 4 (arm 4 is a 8 mm shaft)

Arm-plate and Arm-arm connection precision (hole positions) is important for the rotation to be smooth.

In the image, one arm has only a 8 mm hole for the shaft. This will be changed to 16 mm with F688 in next iteration.

-

#8 Gearboxes

Guidelines for construction

- gear ratio 1/2 (20/40 teeth) or 1/3 (20/60 teeth) * ratio 20 to big wheel

- gearbox from aluminium U profile 40x40x40x2 with length 50 mm (gear 5 longer)

- teethless pulleys are on 5 mm aluminium shaft

- teethes geared pulleys are on 8 mm aluminium shaft, at aluminium case with F688 ball bearings

- screws are M4 all

Gear 1:

Gear 1 will be reworked.

and

Gear 1 is the most complex one, because the 20/60 is belt is routed under the rotation plate to the side under the plate.

The box has size 40x40x40x2 with length about 5 cm. The gear is still 1:3, but will change in next iteration to 1:2 to give a total of 1:40.

Gear 2:

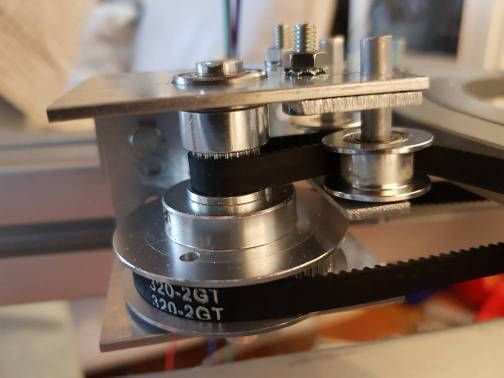

Teethless pulleys near the rotation plate:

The gear is connected to Nema 23. For Nema 23 to be placed in the middle of the arm for better balance, the gearbox has size 40x60x40x2 with length 5 cm.

This version is how I like it:

- the two teethless pulleay near rotation plate have minimum distance to it

- minimum 19 mm distance of teethless pulleys

- minimum distance between teethless 5 mm pulley shaft to 8 mm shaft is 25 mm.

- the 20 and 40 pulleys are on a 8 mm shaft, connected to the gearbox with a F688 and in future with 8x12x0.5 washer between

Gears 3, 4:

- based on 40x40x2 U profile with 50 mm length

- teethless pulleys are on 5 mm shaft

- 20/60 pulley gear is on 8 mm shaft

5 mm screws will be replaced by shaft in next iteration.

Gear 5:

The gearbox is from 40x40x40x2 with length 13 cm. Not finished yet, right will be connected the Extruder. An additional tensioner for the lower 20/60 gear is needed. Size of right Arm 4 axis to left is 10 cm, right will be about 5 cm for Extruder. I let enough room on top to install Nema 17 if necessary. Length from top to bottom is maximum 10 cm, right Extruder + heatbreak + hotend will be about 12 cm. The assembly allows free rotation of axis 5 under arm 3 (free is relative, because wiring and filament will hinder it). Placing the steppers as near to arm 4 as possible for low torque. I'll try to balance arm 4 when finished building.

Belt and distance measuring

To find closed belts which fit well and then measure the distances of the pulleys, I used a little "tool":

-

9/11 Belts, Tensioning

The belts on the rotation plate to the gearbox are open belts, fixed on the rotation plate:

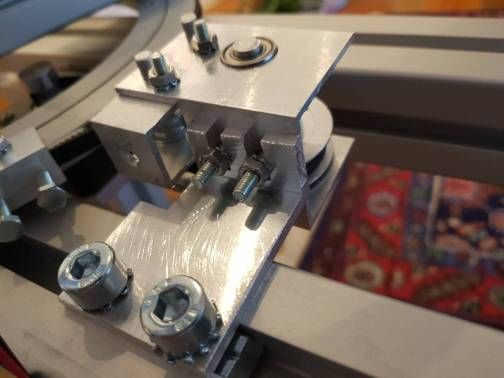

Aluminium L profile 4 mm or more. M4 to fix it at the plate. Two M4 threads with M4 screws on top. GT2 short belt (here steel belt) to make sure belts do not slip. I have no good belt tensioning at the moment.

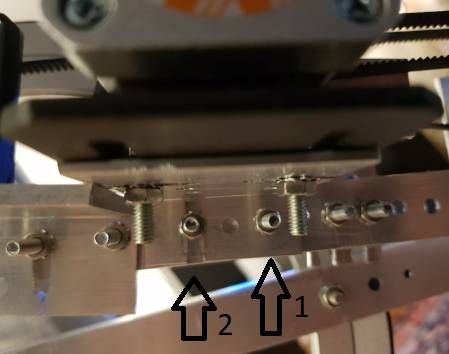

The belts between gearbox and stepper are closed belts. The belt tension is handled by:

First use screw 1 to place the stepper in a distance so belt has a bit tension. Then screw 2 by rotating the stepper so that belt has good tension. The screw 2 has a slot as counterpart instead of a hole:

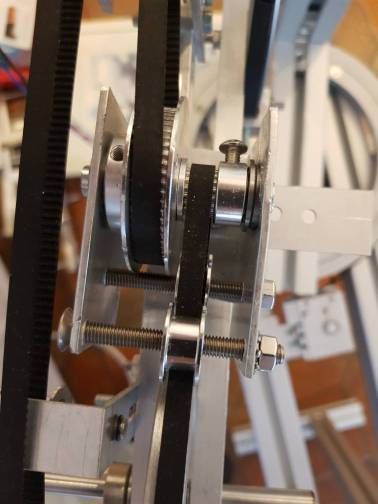

Second the already good tensioned belt with higher tension:

The tensioner is at the middle between gearbox and stepper. Aluminium 2 mm is too weak, 3 to 5 mm needed. The connector between arm and stepper holder should be 3 to 5 mm also, instead of 2 mm, which bends.

Closed Belt lengths:

- Gearbox 1: 20/40, distance xx mm, belt 350 mm (175 teeth).

- Gearbox 2: 20/40, distance 90 mm, belt 240 mm (120 teeth).

- Gearbox 3: 20/60, distance 180 mm, belt 450 mm (225 teeth).

- Gearbox 4: 20/60, distance about 340 mm, belt 760 mm (380 teeth)

- Gearbox 5 first at stepper: 20/60, distance 47.8 mm, belt 180 (90 teeth).

- Gearbox 5 second stage: 20/60. distance 78.5 mm, belt 240 (120 teeth).

-

10/11 Endstops, Calibration

-

11/11 Electronics, Duet Configuration

-

#12 precision analysis

-

#13 improvements

-

#14 BOM lists, weight calculation

-

#15 images of printed things

-

I want to give an update of my robotics development:

The belt gear and hotend construction is working quite good:

The Nema 11 is strong enough for the 1:9 gear and the belt tensioner allows precise rotation. Left and right side are nearly balanced, so axis 4 needs only little force if it stays vertically (maybe using Nema 11 in the future also).

The middle (axis 3 and 4) are working good also, a belt tensioner is important. The rotations produce little vibrations:

The problem right now is the axis 1 and 2. Fast rotation result in big vibrations. I have to improve the construction:

The belt gears are working very good, but high speed results in vibrations of the whole construction. My interpretation is, the vibrations are due to cantilevered constructions, eg arms fixed at one end, but not the other. Or an axis with only one ball bearing. I'll try to improve it.

Next steps:

- build a stable construction of axis 1 and 2, probably by fixing every axis at two points (ie two ball bearings) and parallel arms instead of one. The big aluminium rings (esp. axis 1) are not trustworthy enough, they have too much play, I need to support them with additional axis in the middle like I made it at axis 2, 3 and 4

- one important topic is how to route the wirings, especially the long ones from the hotend. Axis 5 can rotate more than 360 degree, the cables must be able to rotate freely.

-

I've stabilized axis1 and 2 now with this construction:

I've separated the rotation constraint from driving the axis: axis 1 rotates around the vertical shaft which is fixed top and bottom. The driving is done by the horizontal 25 cm rotation plate. The vertical shaft fixes the rotation (and could be replaced later by a 20 or 30 mm shaft, currently it is 8 mm), the horizontal plate needs not to be as precise as before.

The height of the frame is 80 cm now. I'll place the axis 1 actuator behind the construction, so the bed space remains free.

I prepare the hotend to use a toolboard to reduce the wiring mess.

Maybe I'll second every arm with a parallel arm strut to stabilize the horizontal axes 2, 3 and 4.

Next steps:

- reinforce frame

- install axis 1 actuator, left of construction

- install endstops

- route the wiring

- place bed and be creative how to calibrate it. I plan to use 2 actuators for leveling, probably with differential screws

- minor improvements for belt tension

The aluminium plates (big wheels) are not as precise as I hoped. I will change the construction to separate axis as hinge from the rotation force of the plates for the axes 2, 3 and 4 also, like I did for axis 1. But this is a major reconstruction, I will test firmware first with the current construction. When the alu plates have only the task of driving the rotation, I'll try to replace them by 3d printed parts. This will save weight.

-

The connection between the alu extrusion and shaft is built by:

The left black part is very nice, two halfes, can be assembled/disassambled without disassambly of the construction. The washers hinder contact with rotating parts of ball bearing. Ball bearing is F688 (inner 8, outer 16 mm), in middle is SH16/SK16.

-

@JoergS5

I read this for the first time and found some typo? in #2 post.Detent Torque is stepper spedific, but a typical value is 2 Nm for a Nema 17 and 12 Nm for a Nema 23.Isn't it Ncm, not Nm? I check my datasheets again.

Hope your arms are in balance, nevertheless? -

@o_lampe thank you, you're right! I'll correct it. Nm would be nice (but a slow motor).

I am currently rebuilding arm 2, working forward to the hotend. I think stability of frame, arms and hinges is key to precision - but this will be true for every printer type.

The frame around the robot is ugly and dangerous (sometimes the robot touches the frame), I'll try using a 25 mm shaft, fixed at the bottom at two points. The 8 mm shaft bends when the axis rotates.

-

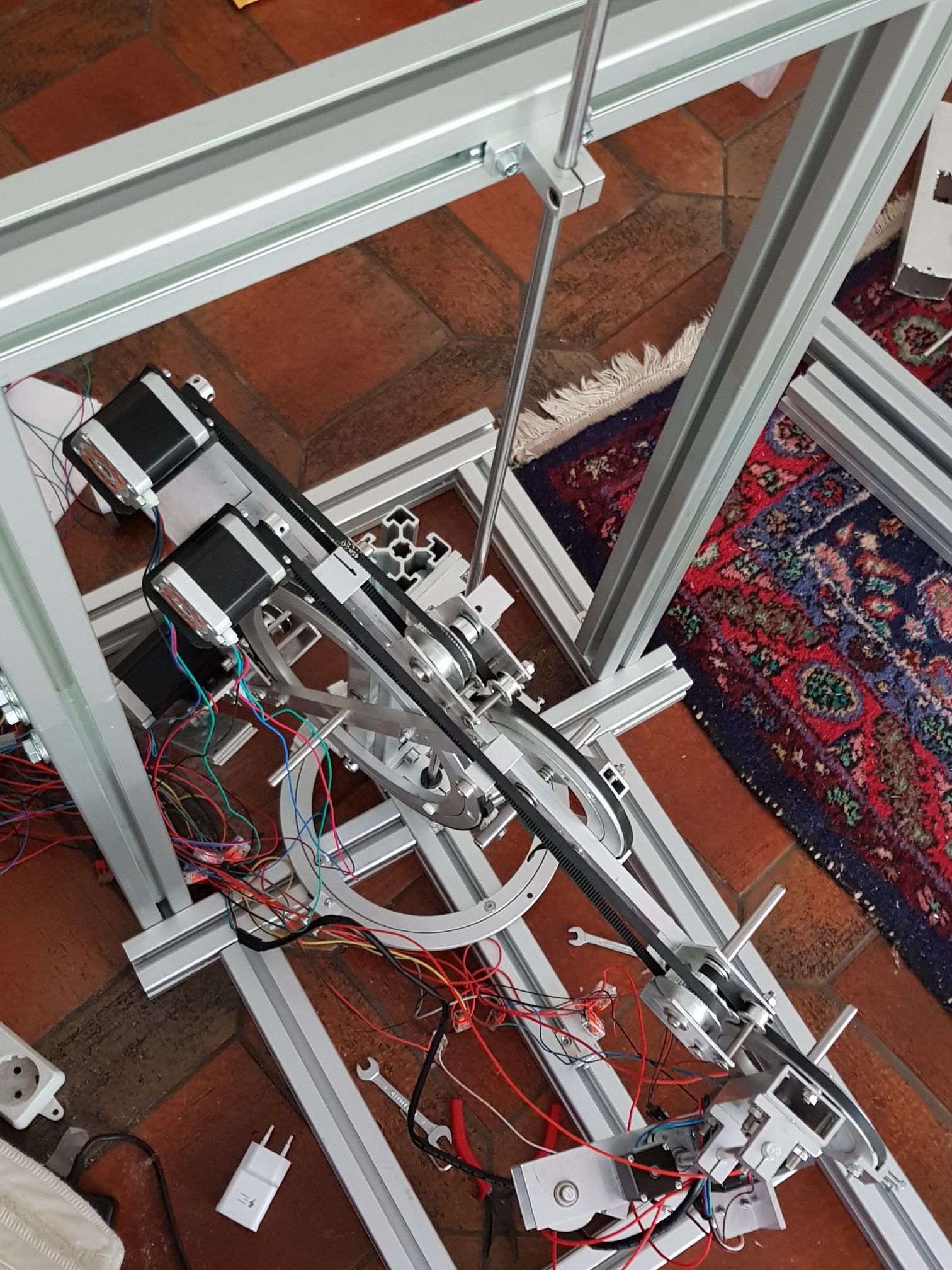

I finished rebuild the axis 1, the following three images show the status:

I implemented the following ideas:

- once I used concrete to build something and put the rest into a bucket, the resulting block is usable to be a weight for printer stability (40 kg). I plan to use concrete to surround the printer later, it's easy and cheap

- using 25 mm shaft with F205 flanged ball bearings at two points (top one upside down)

- shaft - axis 2 connection by SH25 shaft connectors

- reducing wiring mess

- the aluminium plate's task is only to drive the rotation now. The rotation constraint is by the shaft and ball bearings. I may replace the aluminium plate later with a 3d printerd teethed pulley, because it no longer needs to be very stiff.

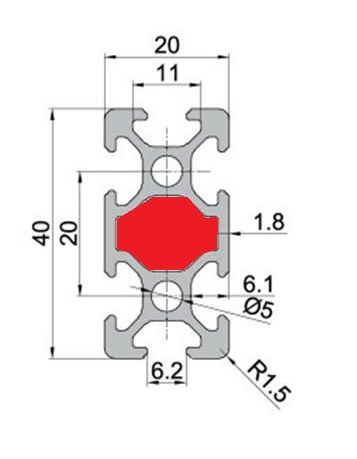

- the aluminium extrusions are Bosch profile 45 based

open problems

- belt tension of the gear toward big wheel is sufficient, but I search a better solution

- the stepper is in the way for the counterweight of axis 2. I'll put it lower with a new adapter

- the endstop trigger and the endstop violate the two-point-rule, they could rotate unintentionally. I'll have to fix it better, but it's low prio

Next step is axis 2. I always try to build the robot without special tools to allow to build is easy for others. But in this case it will be more demanding, as I plan to connect 6205 ball bearings (they are 25 shaft inner diameter) with 60x20x2 aluminium arms. I'll describe how I make it in the next blog.

-

@joergs5 said in Robot Type 1 45 cm - belt gear - direct drive - R0:

I plan to use concrete to surround the printer later, it's easy and cheap

On my CNC I filled the 2040 aluminum extrusions with a mix of fine sand (meant for sandblasting) and epoxy resin. (90% sand, 10% resin IIRC)

It's not easy to fill, better use slow curing resin or very thin concrete?

or very thin concrete?

-

@o_lampe I would say, it depends... For reducing vibrations, it's better if the sand has some room and can take the energy of the vibration by moving itself, so no epoxy. Otherwise the whole construction starts to vibrate (but at a different frequency). The idea of concrete around the printer was to hinder the printer from moving. There are different methods and goals. One of the advantages of your method is that it looks nicer.

-

The idea of concrete around the printer was to hinder the printer from moving. There are different methods and goals.

Well, it's not an either / or decision, you can do both.

-

@o_lampe I totally agree. If I continue as before, my robot prototype will end as a heavy weight commercial robot clone. But that's ok. It will be stiff enough to take a CNC milling head.