Faults trying to configure thick print bed

-

I have a fairly thick print bed and I'm having a really tough time trying to configure it either bang-bang or autotune PID.

If I use M307 H0 B1 in config.g and attempt to heat the bed I get:

Error: Heater 0 fault: temperature rising much more slowly than the expected 1.7°C/sec

But the bed is heating, albeit slowly due to it's large thermal mass.However if I attempt to autotune with:

M303 H0 S100

Then I get: Auto tune cancelled because temperature is not falling

In Phase 2

Also I'll note that the temp rises 10C after it hits the target and shuts off the heater.Here is my config.g:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Fri Sep 25 2020 14:46:33 GMT-0500 (Central Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"TXTFORGED" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M669 K1 X1:1:0 Y0:1:0 Z0:0:1 ;MarkForged Kinematics

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E101 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z600.00 E1500.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z100.00 E10000 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E1680 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-30 Y0 Z0 S1 ; set axis minima

M208 X320 Y140 Z155 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F240 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X45.5 Y-34.4 Z1.85 ; set Z probe trigger value, offset and trigger height

M557 X15:320 Y15:150 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 ; enable bang-bang mode for the bed heater and set PWM limit - was B0 S1.00

M140 H0 ; map heated bed to heater 0

M143 H0 S200 ; set temperature limit for heater 0 to 200C

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S451 ; set temperature limit for heater 1 to 450CM308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create chamber heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H2 ; map chamber to heater 2M308 S3 A"Chamber Fan" P"e3temp" Y"thermistor" T100000 B4138 ; configure sensor 3 as thermistor on pin e3temp (expansion pin 36)

; Bed leveling

; front left (0,0)

; back middle (75,120)

; front right (150,0)

; thread pitch 0.7mm

M671 X39:160:281 Y15:140:15 P0.7; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 T45 H1 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H3 T45 ; set fan 2 value. Thermostatic control is turned on and linked to "Chamber Fan" thermistor; Tools

M563 P0 D0 H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

T0 ; select tool 0; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M570 H0 P60 T15 S60 ; prevent heater errors for bed

M570 H1 P60 T15 S60 ; prevent heater errors for hotend

M570 H2 P60 T25 S60 ; prevent heater errors for chamber

M570 H3 P60 T25 S60 ; prevent heater errors for fake chamber

M501 ; load saved parameters;Set DHCP Networking

M552 S1 P0.0.0.0I'd appreciate any help, there's not a lot online for the temp falling too slowly error. Also, I'll add that the thermistor and heater are functioning properly, it's just a really big bed that takes time to heat and cool.

Thank you.

-

what firmware are you running? 3.2 made changes to the pid tuning

also

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1tempyour thermistor setting is incorrect. find the correct beta value in your thermistor documentation.

-

@Veti Version 3.1.1

It's an E3D Cartridge thermistor.

-

@p8blr said in Faults trying to configure large print bed:

It's an E3D Cartridge thermistor.

that makes no sense

i have not seen a bed that accepts those.Version 3.1.1

update to 3.2

-

@Veti It's a printer that I built myself.

I found this https://e3d-online.dozuki.com/Guide/V6+RepRap+Firmware+Configuration/26?lang=en

Trying to figure out what my values will be...

-

@Veti said in Faults trying to configure thick print bed:

E3D Cartridge thermistor.

so you taped on of those to your bed?

these are the thermistors from e3d that are meant for beds

https://e3d-online.com/products/100k-ohm-ntc-thermistor-semitec?_pos=6&_sid=4dfe4ab04&_ss=r -

@Veti I machined a pocket in my bed and have it mounted internally near the print surface. I chose the cartridge style because it came with a micro-molex connector so it would be easy to replace.

Going off this post:

https://forum.duet3d.com/topic/9851/confusion-about-semitec-104gt-2-b-value-in-documentationMy new values will be:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C0.0000000706

And I will also try to update the firmware next.

-

I was able to get it working and I just wanted to post what I did.

-Updated firmware to 3.2

-Changed B and C settings for my thermistors

-Ran autotune and it worked this timeThis is the new M308 Settings:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp, E3D cartridge thermistor

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp, Slice Engineering Mosquito Thermistor

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 2 as thermistor on pin e1temp, E3D cartridge thermistorAnd these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0Thanks.

-

@p8blr said in Faults trying to configure thick print bed:

And these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0You likely know this already but I will mention just to be safe.

If you don't like having configuration values in two files you can always move the contents of config_override.g into config.g at any locations in the file you deem appropriate.

Frederick

-

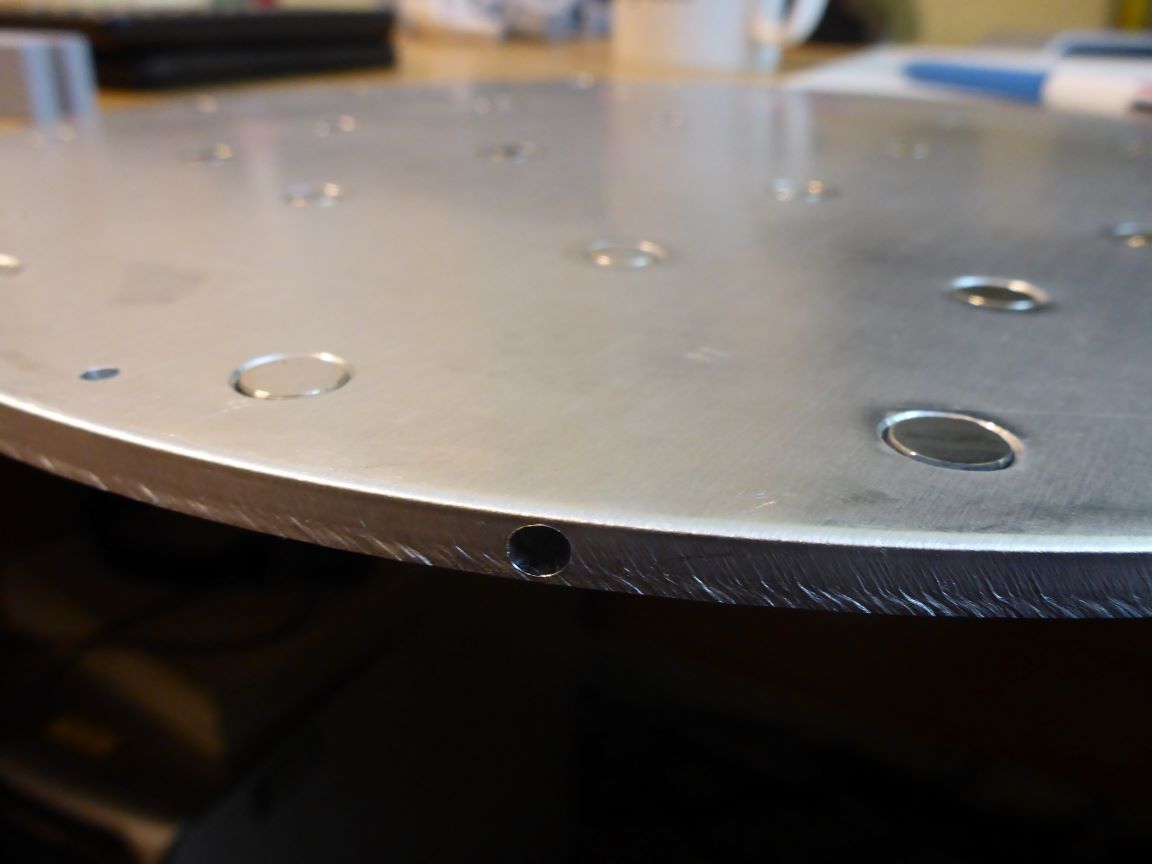

@Veti For info, I too use an E3D cartridge style thermistor on my bed. It sits inside a 3mm diameter hole, about 30mm deep, that I drilled in the edge of the

bed10mm thick aluminium plate so that the thermistor is de-coupled form the heat pad/aluminium plate junction. The hole is also as close to the top surface as I could get it without braking through - so the sensor reads the temperature where it matter. -

@p8blr said in Faults trying to configure thick print bed:

I was able to get it working and I just wanted to post what I did.

-Updated firmware to 3.2

-Changed B and C settings for my thermistors

-Ran autotune and it worked this timeThis is the new M308 Settings:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp, E3D cartridge thermistor

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp, Slice Engineering Mosquito Thermistor

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 2 as thermistor on pin e1temp, E3D cartridge thermistorAnd these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0Thanks.

That's an incredibly long dead time. Can you tell us a little more about the dimensions of the bed and the thermistor mounting "pocket" - especially how it is orientated with respect to the heater pad?

BTW, I use a 400mm / 400mm x 10mm thick plate with an 800 watt heater - for the sake of comparison, here is my latest tuning result using RRF3.2

M307 H0 R0.104 C2186.5 D28.16 S1.00 B0 V0Edit. Mine is a mains powered heater via an SSR - I guess yours is 24V yes?.

-

@Veti as @deckingman said, and it works well:

Mine is about 40mm deep, 3.5mm diameter hole in a 6mm thick bed plate. Actually at the moment it has a PT100 cartridge in it, but it could take a thermistor cartridge.

My D is about 46. I think if you are measuring temperature of the plate (rather than of the heater element) you'd expect a longer dead time.

M307 H0 R0.243 C1212.7 D46.41 S1.0 V0 B0 -

I have no problem with the duet software with a heat bed of 12mm thick aluminum and heat bed with 10mm Showing results for borosilicate glass

Bother were 300mm X 600mm. You need to make sure that your heater is able to get up to temperature quick enough. I am using a mains powered heater. -

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time. -

@Veti said in Faults trying to configure thick print bed:

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time.Depends on the size of the heat pad and how deep the hole is.

-

@Veti said in Faults trying to configure thick print bed:

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time.I haven't got access to a thermal camera to check the coolness at the edges, but the sensor cartridge is well inside the footprint of the heater element (in mine, at least). The heat doesn't have to spread outwards, only through the plate.