G30 S-1 is giving me heart stitches [SOLVED]

-

@fcwilt said in G30 S-1 is giving me heart stitches:

G1 S1 Z-300 F600 - is incorrect - remove it - you are going to use the z probe for homing Z

G1 Z5 F200 - should generate an error as Z is not homed - remove itAs I said earlier, I have to home the Z-axis before running G30. And that's exactly what it does. And it does lift 5mm afterwards, because the axis is now homed according to DWC.

The only it doesn't do, is giving me a Z=0 datum. also G92 Zxxx doesn't.That's why I had to deal with G30.

-

there G30 does not need the z axis to be homed

-

@o_lampe said in G30 S-1 is giving me heart stitches:

Read it all:

Snnn 1 = switch-type (eg microswitch) endstop input, 2 = Z probe (when used to home an axis other than Z), 3 = single motor load detection, 4 = multiple motor load detection (see Notes).

M574 Z0 is correct.

Frederick

-

@fcwilt

where's that from, please? -

@o_lampe said in G30 S-1 is giving me heart stitches:

@fcwilt

where's that from, please?Where is what from?

Frederick

-

@o_lampe said in G30 S-1 is giving me heart stitches:

As I said earlier, I have to home the Z-axis before running G30. And that's exactly what it does.

Because you didn't have M574 Z0 saying to home with the z probe.

Frederick

-

@fcwilt said in G30 S-1 is giving me heart stitches:

2 = Z probe (when used to home an axis other than Z)

Sorry, I should've quoted it...

Here is the link, I refered to -

@o_lampe said in G30 S-1 is giving me heart stitches:

@fcwilt said in G30 S-1 is giving me heart stitches:

2 = Z probe (when used to home an axis other than Z)

Sorry, I should've quoted it...

Here is the link, I refered toI thought you had upgrade to v3 firmware. Have you not done so yet?

Frederick

-

@fcwilt

here's another quote, I took from wikiExample M574 X1 Y2 Z0 S1 ; X endstop at low end, Y endstop at high end, no Z endstop, all active highWhat's wrong with that compared to your M574 Z0?

-

@o_lampe said in G30 S-1 is giving me heart stitches:

@fcwilt

here's another quote, I took from wikiExample M574 X1 Y2 Z0 S1 ; X endstop at low end, Y endstop at high end, no Z endstop, all active highWhat's wrong with that compared to your M574 Z0?

It looks like you haven't upgraded to v3 firmware - I thought you were going to do that.

Frederick

-

@fcwilt said in G30 S-1 is giving me heart stitches:

It looks like you haven't upgraded to v3 firmware - I thought you were going to do that.

OK, I see.

One step at a time... Covid lockdown allows me to be very generous with my time... -

@o_lampe said in G30 S-1 is giving me heart stitches:

@fcwilt said in G30 S-1 is giving me heart stitches:

It looks like you haven't upgraded to v3 firmware - I thought you were going to do that.

OK, I see.

One step at a time... Covid lockdown allows me to be very generous with my time...My apologies for I thought you were using v3 and the code I was showing you is all for v3.

Which is code I tested.

I cannot help you with v2 effectively and I have no boards with v2 firmware and thus cannot test my code.

Again my apologies for the misunderstanding and resulting confusion.

Frederick

-

@Veti said in G30 S-1 is giving me heart stitches:

there G30 does not need the z axis to be homed

That's the whole story I'm trying to tell.

On rrf2.05.1 I have to home all axis' to run a G30. Tried to home X and Y only, but NO.And then it does some horizontal moves, probes here 'n there and crashes eventually.

-

that is not true.

the z axis does not need to be homed.

i just tested it

G92 X15 Y15

G30the G30 is executed without a problem

-

@o_lampe said in G30 S-1 is giving me heart stitches:

G30 X20 Y20 S2 ; is a valid code,right?

No. Never has been. G30 when homing Z in homeall should be by itself. To position it first, use a G1 XY move before it. And yes, before you can move XY those axis must be homed otherwise it will complain. You can force an unhomed axis to move anyway with the S2/H2 switch, but that's really only feasible for the Z axis to lift it out of the way before moving XY. If you were to use S2/H2 with XY you wouldn't be sure that the position was correct.

-

Just for fun I took your values as best as I could gather and put them in the configurator and generated a clean 2.05 config.

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Thu Jan 21 2021 12:09:47 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z2500.00 E400.00 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E600.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y150000.00 Z720.00 E3000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z100.00 E1000.00 ; set accelerations (mm/s^2) M906 X1500 Y1500 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z-2 S1 ; set axis minima M208 X280 Y170 Z250 S0 ; set axis maxima ; Endstops M574 X1 Y1 S3 ; set endstops controlled by motor stall detection M574 Z1 S2 ; set endstops controlled by probe ; Z-Probe M558 P5 H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:170 S20 ; define mesh grid ; Heaters M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Thu Jan 21 2021 12:10:56 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-285 Y-175 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-285 ; home X axis G1 H1 Y-175 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-285 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-175 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X15 Y15 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning -

And the same, but for RRF3 for comparison.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Thu Jan 21 2021 12:12:55 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z2500.00 E400.00 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E600.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y150000.00 Z720.00 E3000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z100.00 E1000.00 ; set accelerations (mm/s^2) M906 X1500 Y1500 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z-2 S1 ; set axis minima M208 X280 Y170 Z250 S0 ; set axis maxima ; Endstops M574 X1 S3 ; configure sensorless endstop for low end on X M574 Y1 S3 ; configure sensorless endstop for low end on Y M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P5 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:170 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Thu Jan 21 2021 12:13:24 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-285 Y-175 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-285 ; home X axis G1 H1 Y-175 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-285 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-175 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X15 Y15 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioningIn case you wanted to update. If you still have access to DWC. Upload these 3 zip files, one at a time. Don't extract them. Reboot after each.

https://github.com/Duet3D/RepRapFirmware/releases/download/2.05.1/Duet2Firmware-2.05.1.zip

https://github.com/Duet3D/RepRapFirmware/releases/download/3.0/Duet2and3Firmware-3.0.zip

https://github.com/Duet3D/RepRapFirmware/releases/download/3.2/Duet2and3Firmware-3.2.zip

That will get your firmware and DWC up to date.Then you could upload this json template to the configurator to load what I started and make whatever corrections I didn't get right. I didn't adjust for your thermistors or zprobe specifics.

-

@Phaedrux said in G30 S-1 is giving me heart stitches:

; Z-Probe (config for 2.05)

M558 P5 H5 F120 T6000 ; set Z probe type to switch and the dive height + speedsG31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

Thanks @Phaedrux for the great efford.

It seems, all of you want to get me in line which is great!I compared my own config with this and the biggest difference, is the P500 value in the G31 command line instead of M558

Furthermore, I haven't seen a definition in your config, that I might have forgotten in mine.

(that was my biggest hope: some incomplete definition messing up the config)Sure enough, I will test your config after editing a few setting (missing probe offset and XY/stepper != stall detection)

If it works, I can finally step on and generate a crash_free heightmap.

-

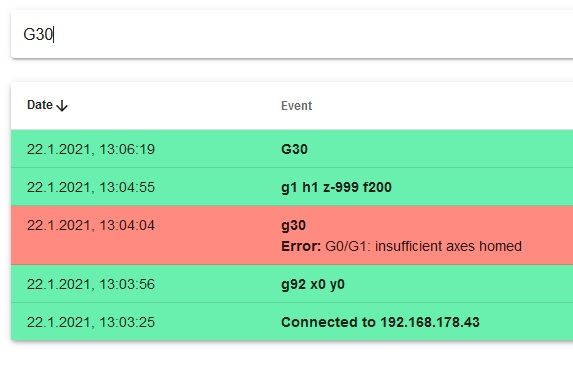

This is the latest report:

I've updated to rrf3.2, changed a few minor settings from the config file I got from @Phaedrux (Z motor and probe needed to be inverted)

But still...

I also changed the z-probe port from zprobe.in to e1stop, but no change.

Anyone any idea? @fcwilt I'm now on rrf 3.2, you can chime in anytime

Is it possible I have my XY stepper config wrong? Their connectors would fit the Molex headers in both ways. They move the right way, but you never know...this is my last straw.

-

can you post your new config? and homing files?