No readings: PT1000 temp sensors on Duet 2 Wifi expansion header

-

Hi there

Some might know our large-scale 3D-printer project, which we have been working on for almost a year now. Currently we are finalizing the pellet extruder setup by adding PT1000 sensors.

Those sensors have 15m cables each and they are terminated on a proto board connected to the Duet2 Wifi expansion header.

In detail we are using the Thermistor 3-6 and the VSSA pins to connect the sensors. Now the issue is that we don't get any readings on those pins. The function of the sensors is confirmed on the thermistor inputs directly on the Duet board. On the on-board inputs we get correct room temperature readings. So, sensor hardware failure is ruled out.

Also I've double checked our proto board's connections by measuring the resistance across T3-6 and VSSA directly on the expansion header. They are all correct.

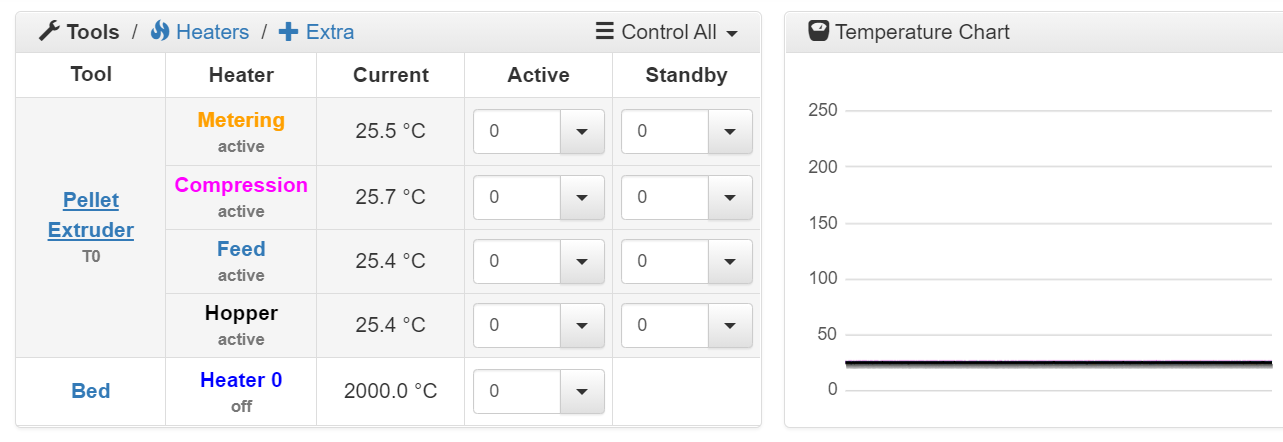

; Configuration file for testing Duet Ethernet and Wifi ; Communication and general M111 P1 S0 ; Debug off M550 XXXX ; Machine name and Netbios name (can be anything you like) M551 XXXX ; Machine password (used for FTP) ;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits M540 XXXX ; MAC Address ;*** Networking - Enable for both WiFi and Ethernet boards. M552 S1 ; Turn network on ;*** Ethernet networking: Adjust the IP address and gateway in the following 2 lines to suit your network M552 P192.168.1.14 ; (0 = DHCP) M554 P192.168.1.255 ; Gateway M553 P255.255.255.0 ; Netmask M555 P2 ; Set output to look like Marlin G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ;;;; HANGPRINTER SPECIALS (M669, M666) BEGIN HERE ;;;; M669 K6 ; This is a Hangprinter enables ABCDV-parameters in gcodes that refer to motors M584 V9 A6 B5 C7 D8 P5 ; map ABCDV-axes to ext driver pins (four visible) M584 E0:1:2:3:4 ; Regard all TMC2660s as extruder motor drivers M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M569 P4 S1 ; Drive 4 goes forwards M569 P5 S0 R1 T5:5:10:1 ; Drive 5 (A) goes forwards M569 P6 S0 R1 T5:5:10:1 ; Drive 6 (B) goes backwards M569 P7 S0 R1 T5:5:10:1 ; Drive 7 (C) goes forwards M569 P8 S0 R1 T5:5:10:1 ; Drive 8 (D) goes backwards M569 P9 S0 R1 T5:5:10:1 ; Drive 9 (V) goes backwards M669 A0:-1437.13:-216.00 ; Anchor Ax:Ay:Az M669 B1244.59:718.56:-216.00 ; Anchor Bx:By:Bz M669 C-1244.59:718.56:-216.00 ; Anchor Cx:Cy:Cz M669 D3706.1 ; Anchor D = Distance between the anchor pivot point D and the end effector pivot point D M669 P500 ; Printable radius M669 S200 ; Segments/sec M666 Q1 ; Line Spool up compensation = 1 M666 R50.1:65.1:65.1:65.1:65.1 ; Spool radii of A:B:C:D:V spools ; The following is assumed ; by the auto calibration script ; to be constant for all HP4s M666 U1:2:2:2:1 ; Mechanical advantages on ABCDV M666 O1:1:1:1:1 ; Number of lines per spool M666 L5:20:20:20:20 ; Motor gear teeth of ABCDV axes M666 H300:255:255:255:255 ; Spool gear teeth of ABCDV axes ; Adjust the following to match your ODrive settings M666 J32:32:32:32:32 ; Full steps per ABCDV motor revolution M350 X16 Y16 Z16 V16 E16 ; Configure microstepping with interpolation M208 Z3706.1 ; set maximum Z at D anchor. See M669 ... D<number> M201 X6000 Y6000 Z6000 V6000 E2000 ; Accelerations (mm/s^2) M203 X120000 Y120000 Z60000 V60000 E15000 ; Maximum speeds (mm/min) M574 X2 Y2 Z2 V2 S1 ; set endstop configuration (all endstops at high end, active high) M906 X1200 Y1200 Z1200 V1200 E1400 I60 ; Set motor currents (mA) and increase idle current to 60% M566 X10000 Y10000 Z10000 V10000 E7000 ; Maximum instant speed changes mm/minute ; Thermistors M305 P3 X501 R4700 S"Metering" ; Put your own H and/or L values here to set the metering zone thermistor ADC correction M305 P4 X504 R4700 S"Compression" ; Put your own H and/or L values here to set the compression thermistor ADC correction M305 P5 X505 R4700 S"Feed" ; Put your own H and/or L values here to set the feed zone thermistor ADC correction M305 P6 X506 R4700 S"Hopper" M570 S300 ; Hot end may be a little slow to heat up so allow it 180 seconds ; Tool definitions M563 P0 S"Pellet Extruder" D0:1 H3:4:5:6 ; Define tool 0 M567 P0 E1:0.9 ; Set tool 0 mixing ratio for main motor and auxiliary motor G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures M92 E415 ; Set extruder steps per mm M208 S1 Z-10.0 ; set minimum Z T0 ; select first hot end ; Enable Fan 1 thermostatic mode for heater 1 (E0 HEAT) at 45 degrees M106 P0 X255 T45 H3:4:5:6The Metering zone sensor is currently connected to the on-board input, but it will go onto the expansion header also.

The sensors on the expansion header give 2000c & fault.

Any ideas where to start looking?

I just unplugged two of the sensors on the expansion header, and I noticed that after a while the readings on those channels start to drop gradually from 2000c. This might be due to the firmware?

-

You need to connect a reference resistor between each expansion connector thermistor pin you are using and the VREF pin on the expansion header. For PT1000 sensors, I suggest 2K2 0.1%. Then specify the value you are using in the M305 or M308 command.

-

Hey, wow!

Thanks David for the prompt answer!

Will try that out next -

@Bloft-Design-Lab said in No readings: PT1000 temp sensors on Duet 2 Wifi expansion header:

Those sensors have 15m cables

be aware that the 15m cable will increase the resistance and cause a shift in the reading.

-

@Veti said in No readings: PT1000 temp sensors on Duet 2 Wifi expansion header:

@Bloft-Design-Lab said in No readings: PT1000 temp sensors on Duet 2 Wifi expansion header:

be aware that the 15m cable will increase the resistance and cause a shift in the reading.

Yes, that was/is also our concern, but since we get pretty accurate readings on the duet on-board thermistor pins, I'm confident that the length will not be a problem.

-

BTW likes the video on twitter of the extruder heater LED feedback. looks like you guys are close to printing!

-

@Veti said in No readings: PT1000 temp sensors on Duet 2 Wifi expansion header:

@Bloft-Design-Lab said in No readings: PT1000 temp sensors on Duet 2 Wifi expansion header:

Those sensors have 15m cables

be aware that the 15m cable will increase the resistance and cause a shift in the reading.

PT1000 sensors are ten times less sensitive than PT100 in this respect. Each ohm of cable resistance will increase the reading by about 0.25C.

-

Very nice! Only few centigrade off.

@T3P3Tony originally we wanted to have the temp daughterboards attached to the extruder as well as an Arduino Nano for reading out them. The very same Nano controls also the LED color based on the average temperature. For time being we have to transfer the temp to the Duet and then the RGB signal back to Nano.

Of course now we will have the option to adapt the temperature range of the LED color to the actual temperature set point, what makes this even better.

Anyway, thank you very much! Now, it should be pretty safe to say that first prints are to be expected next week. Of course we will post videos