Delta print dimension Issues - smart effector

-

-

-

@polbofree said in Delta print dimension Issues - smart effector:

Hello guys,

I have some problems with my delta printer.

I read all documentation about smart effector configuration and setup, but when I print the dimensions of X Y and Z tower are wrong.

For example I printed a calibration hexagon with 80 mm and the results are:

X axis 80,6mm

Y axis 80,7mm

Z axis 80,2mmHow can i fix it?

The delta rods are perfect with same lenghts.

ThanksThe Z axis error is small and best ignored. The other two errors are near enough equal. You can adjust the X and Y scale by making a small adjustment to the M665 L parameter. For example, if you are currently using L360 than the new value should be (80/80.65)*360. After changing the L parameter, run auto calibration again because the delta radius will have changed slightly.

Alternatively, use the M579 command to scale the axes.

-

@dc42

Thanks for your prompt answer.

Z axis is refered to third tower of delta printer, not to third axis of piece.Any tower on my printer give me different measure

-

@polbofree said in Delta print dimension Issues - smart effector:

Z axis is refered to third tower of delta printer, not to third axis of piece.

I'm sorry, I failed to read your post completely. Evidently there is a geometric error somewhere. See https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Make_sure_your_build_is_accurate for common causes. The Smart Effector avoids many possible errors but not all, e.g. carriages rotated slightly either in the Z plane or perpendicular to the carriage face.

It's possible to adjust individual rod lengths in the M665 command to counter this sort of error, but if you do that then print a large noughts-and-crosses/tic-tac-toe pattern before and after to check for non-linearity.

-

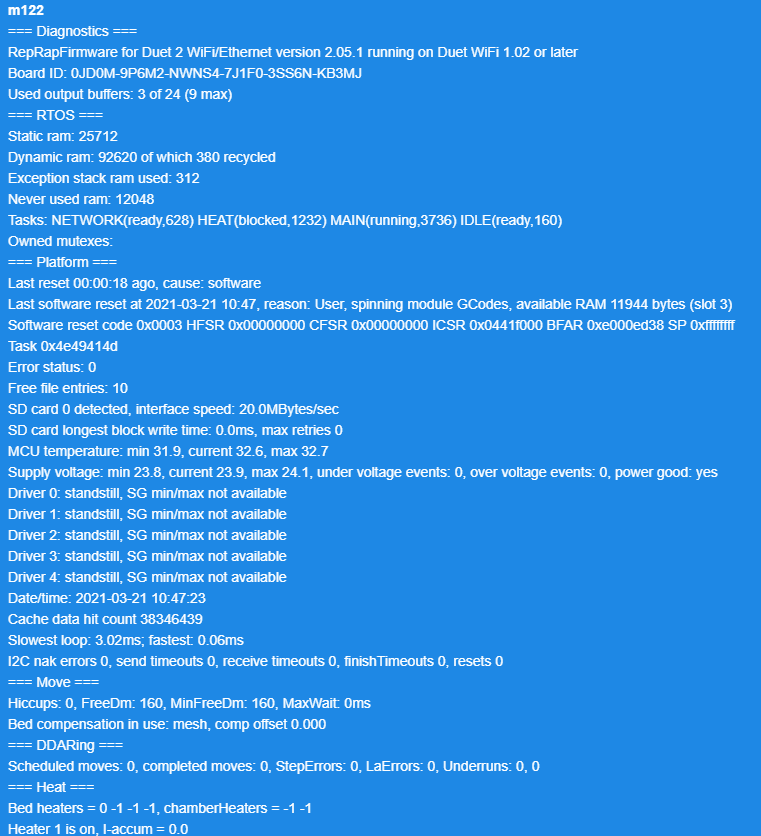

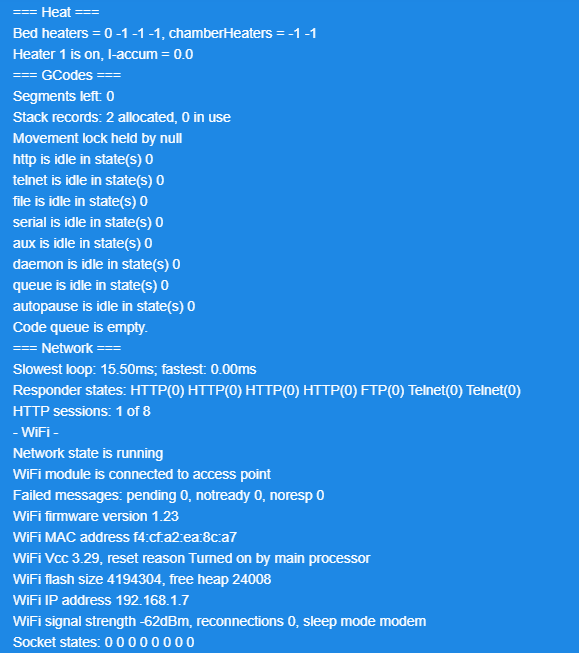

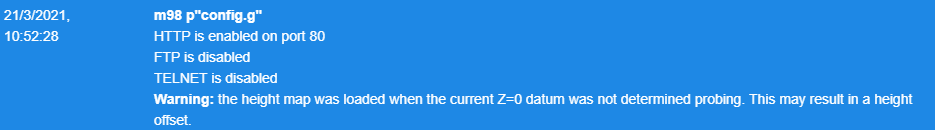

@polbofree you are also loading your heightmap from within config.g which is not recommended (you can see you get a warning for it!). You should only load the heightmap after you've set the Z=0 position using your z probe (I.e. a G30). Typically you'd only load it when you start a print (I have G29 S1 in my start.g). You should also only create your heightmap after you've set your z=0 position with your z probe (you may have done this).

Not sure if this will solve your issue though as your bed.g cancels your heightmap. As dc42 says, I'd check through the mechanicals first.

-

@engikeneer you advice me to delete G29 command into config.g and repeat configuration with G30?

-

@polbofree yes delete the G29 S1 from config. when the config.g is run at boot, you haven't homed your axes, so the printer has no idea where Z=0 is.

Here is my start code for a print (I have this in my slicer, but you could put it in start.g). I home my delta (my homing file is very similar to yours but I don't comment out the last 2 lines), drop the nozzle down to Z=5, then probe the bed with a G30 to accurately set the bed height. I then activate mesh compensation by loading my heightmap

G28 ; home all axes G1 X0 Y0 Z5 F5000 ; drop nozzle G30 ; probe bed G29 S1 ; activate mesh compensation G1 Z15; lift nozzle To create a heightmap, I have a little macro (see below). You can see here I also home, then use the probe to accuarately set the Z=0 height. Then I do G29 to create the heightmap. Note that my G30 probe to set the Z=0 height is always at the same point before creating and loading the heightmap (0,0).

M561 ; disable any mesh compensation G28 ; home all axes G1X0 Y0 Z5 F5000 ; drop nozzle G30 ; probe bed G29 ; run mesh compensation As I said before, I doubt this will fix the issue you're seeing with dimensional accuracy, but it may help with getting a better/more consistent first layer.

Edit: this is all covered in abit more detail on the wiki page for using mesh compensation https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation

-

@engikeneer said in Delta print dimension Issues - smart effector:

As I said before, I doubt this will fix the issue you're seeing with dimensional accuracy, but it may help with getting a better/more consistent first layer.

When I send G30 S1 command, the nozzle hit the bed ang retur ne avery a different value.

If I try some times, I give:

-0.41

-0.43

-0.44

-0.43

-0.47

-0.43

-0.45

-0.51

....the nozzle is clean. Is it normal to have that differences?

-

@polbofree I'd hope you gould get a bit better than that, but I don't have a smart effector so can't say for sure. I would say that such variations could also impact how accurate your delta calibration is so I would definitely look at improving it. A couple of things to think about/check:

Are you probing with a hot nozzle? When I used a nozzle contact piezo I always heated to 130deg C and did a double probe (i.e. two G30's). That was hot enough that any filament on the nozzle got squished after the first probe, but if I went much hotter, the nozzle would damage my bed surface (I use a Ziflex flex plate).

Have you gone through the smart effector comissioning wiki page (particularrly the section on settingb the sensitivity)? https://duet3d.dozuki.com/Wiki/Smart_effector_and_carriage_adapters_for_delta_printer#Section_Commissioning

Your M558 in config uses probe type P5, but I beleive P8 is recommended (it's the same but unfiltered for a faster response)

In general, nozzle contact probes require a stiff mechanism to get a reliable result. Any backlash/flex issues in your delta arms or carriages could be giving you issues (and could be a source of your dimensional errors?)

You can use the A & S parameters in your M558 definition in config to setup repeated probing to improve accuracy. I do this on all my printers, but would generally try and improve everything else first. Typically I use A10 S0.01 (so it keep probing until two results are within 0.01mm of each other and take the average of those two, but if it gets to 10 probes it just take the average of all 10)

Hope that helps!