HELP! Duet 2 WiFi Configuration and DWC Upload???

-

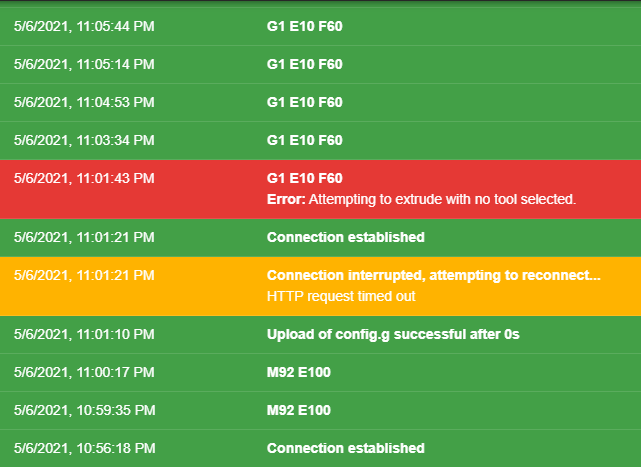

So, I'm trying to calibrate my E-steps, but it seems no matter how slow I try to set it, it goes fast, and no matter what length I set it to extrude, it seems to extrude forever until I eventually have to E stop it, so I don't waste filament .

The guide says to run G1 E100 F60, and 60mm/sec is pretty fast but I ran it anyway. But it says to set it low, so I manually hit 1mm/sec and to extrude 100mm and I got the same results for both...Fast and never ending filament extrusion.

-Not sure what to do

Thanks

-Carson

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

G1 E100 F60, and 60mm/sec

F60 is 60mm/min, so only 1mm/s which is slow.

If it's still going very fast it could be that your steps per mm is very wrong from what it should be.

What is the extruder? The default creality bowden setup for the ender5?

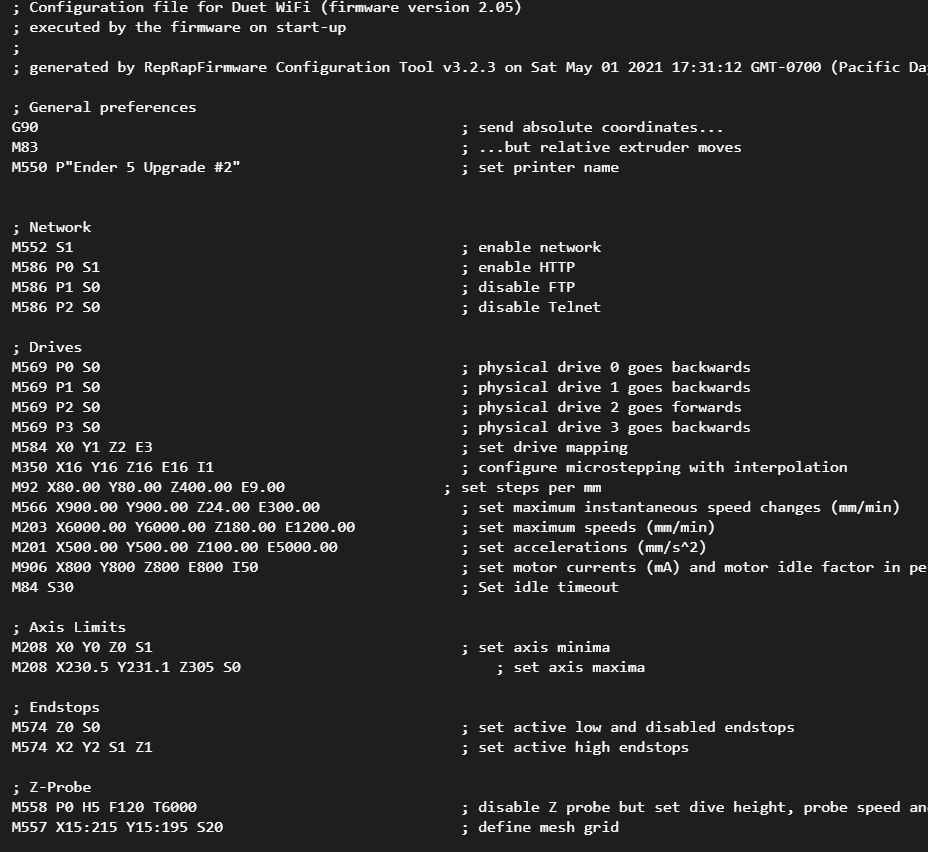

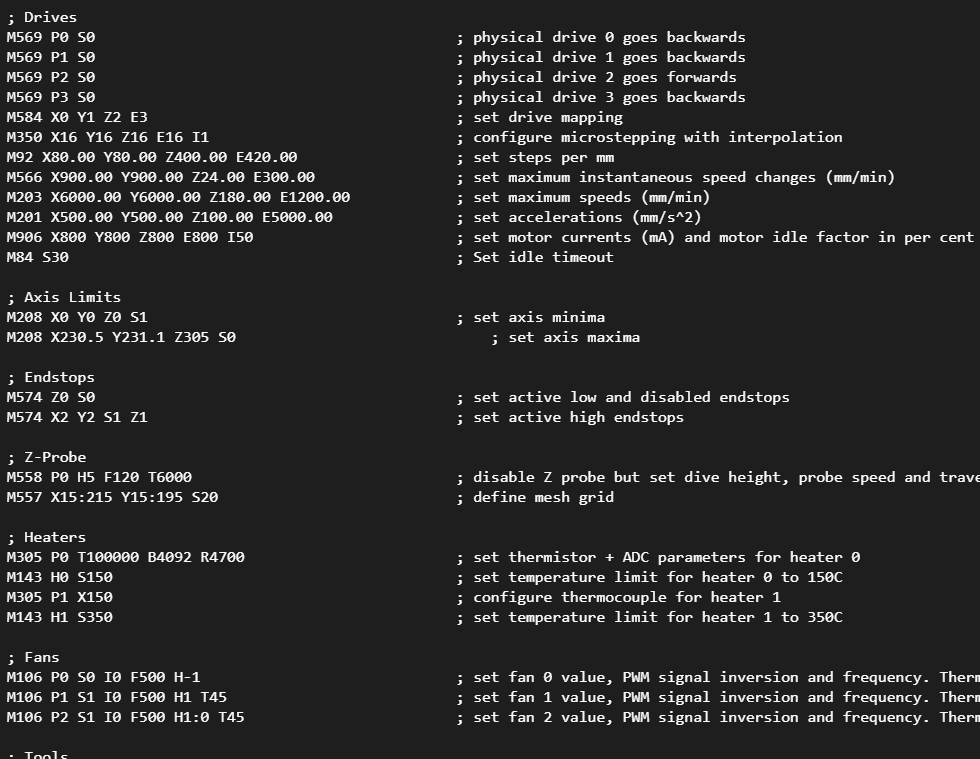

M92 X80.00 Y80.00 Z400.00 E420.00

E420 could be quite wrong if it's teh stock. I think it would be more like E90

-

It's a Micro-Swiss All Metal Hotend Direct Drive.

But yeah it's going really fast. In about 15 sec i had like over 300mm. And it just keeps going and going.

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

It's a Micro-Swiss All Metal Hotend Direct Drive

And what kind of motor on it? 200 or 400 steps per rotation?

Like this?

https://store.micro-swiss.com/products/micro-swiss-direct-drive-extruder

-

Yes, that's the correct one, although it didn't come with a motor so I'm using the Ender 5 stock motor which is 400 (I'm almost positive it's a 400 step motor 99.9%)

Thanks

-Carson

-

Well if it's extruding way too much with 400 steps per mm, try 100 steps per mm. Extrude a small amount to start with to see how it goes.

M92 E100

G1 E10 F60 -

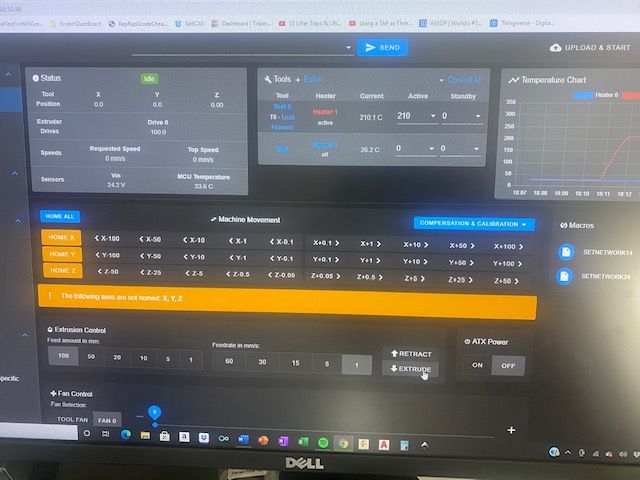

So after changing M92 in the config file, and commanding G1 E10 F60, it is now extruding at a slow speed but I think it's still extruding too much. If I'm understanding the command correctly E=Speed and F= mm of filament to be extruded, correct?

-I ran the command 3 times and got a length of 100mm each time.

-Am I missing something, or is that what was supposed to happen?

Thanks,

-Carson

-

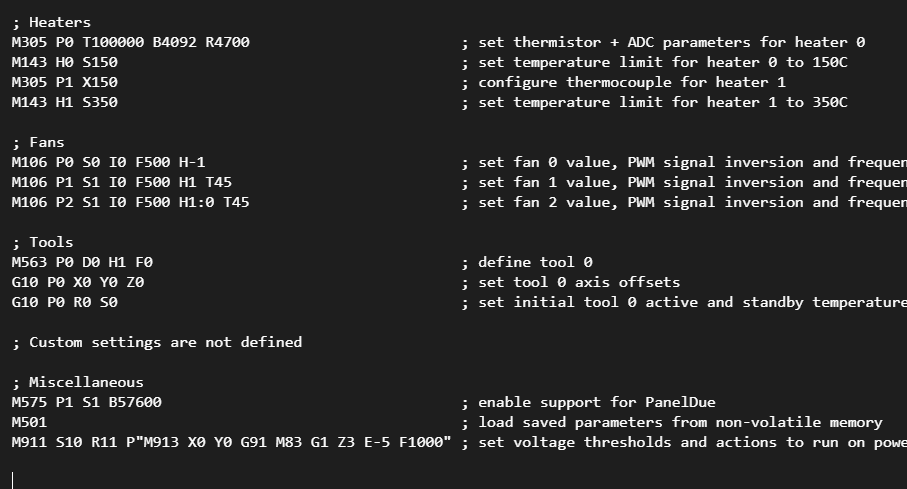

@pcnoobneedsmajorhelp in a G1 command, E is the amount of movement command from the Extruder in mm. F is the feedrate (speed) in mm/min.

Did you reboot after changing the M92 in config.g?

Also, you can just send the M92 command in the console in the web control (e.g. while you're setting it up to find the right value), then update the config when you've found the right value to use.

Edit: the amount of extruder movement is measured in mm of raw filament being fed into the hotend. Of you're commanding 10.. and it's pushing through 100mm, then your M92 value must be 10x too high

-

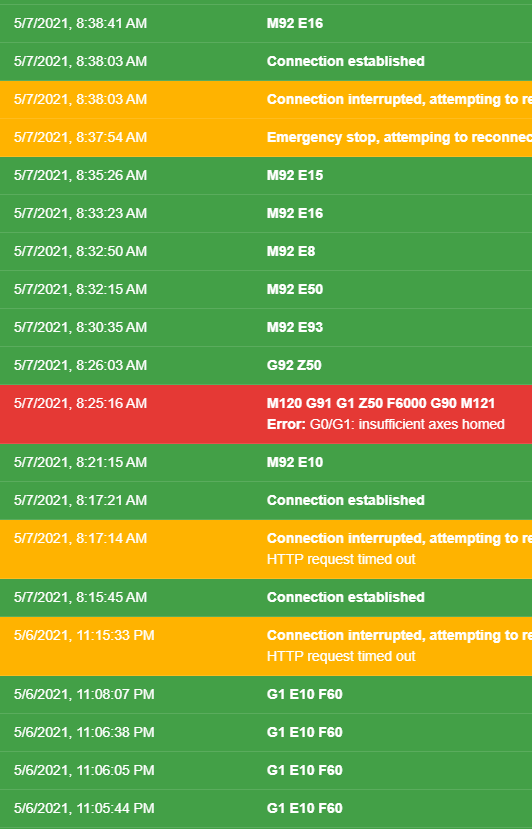

Well that didn't work. I tried it all the way down to 4 and it just keeps going forever. Or not going enough. every time i try it i get a different result. Plus when have you ever hear of a stock ender stepper motor doing lower than 93. Also i noticed that my PanelDue is not in sync with the DWC and it also wont send commands from the PanelDue (unresponsive).

-

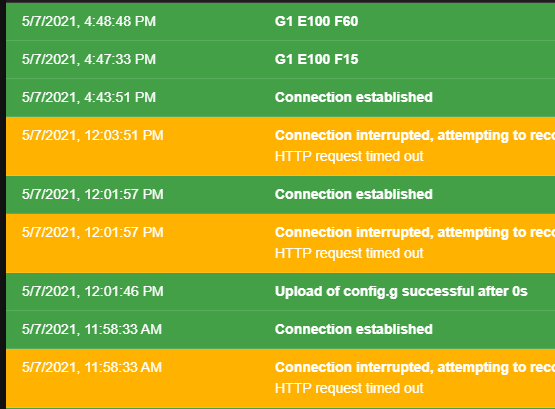

Now the DWC is not responding. And yes I'm connected to WiFi

-

Is it possible you've sent a very long running command causing things to appear unresponsive?

Do things return to normal after a power cycle?

How have you set the steps per mm and what command are you sending for the extruder test?

-

I've cycled the power several times and it still either isn't responsive or is a never ending extrusion. I first had it at 100, then I tried 10, then 4, 14, 15, 8, and lastly 16 and out of all those 8 was the closest at 25mm so I tried 16 to see if I could get close when I set it at 50mm. All the other ones either ran forever or were just way too long. There doesn't seem to be any rhyme or reason to it either. So I have 2 theories. 1: (there are relatives in town using up more bandwidth than usual so..) slow internet connection=lag in responsiveness. Or 2: the motor is broken.

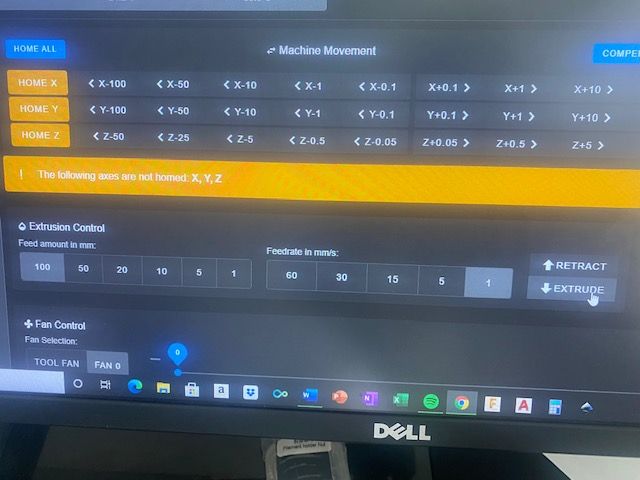

-On the DWC I've commanded E10 F100, E10 F60. After than I manually clicked it to feed 10mm, at a speed of 1, then 5, then 30(which was wayyyy too fast). Then I tried 100mm at 1 and 5. And they don't reflect at all on my PanelDue.

-

Can you post your current config as it is now so we can see what it's setup like?

It's an ungeared extruder, so the steps per mm will be pretty low regardless of the motor.

Have you tried following along with this? https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

-

-

You can add

T0to the end of your config.g so that the first tool is selected at startup.I would suspect that the M92 E steps per mm is in the range of 90 - 120.

Extruding 100mm at 1mm/s will take... 100 seconds if the steps per mm are accurate, so you will need to be patient.

-

Yes, I know this lol, that's why this is so frustrating and infuriating, because it's not even close. That's why I had my E steps set at 9, because nothing else is working and I'm ready to throw this thing out of the window.

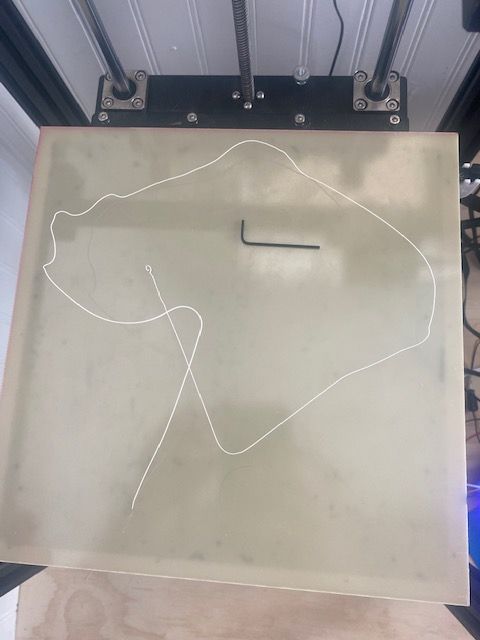

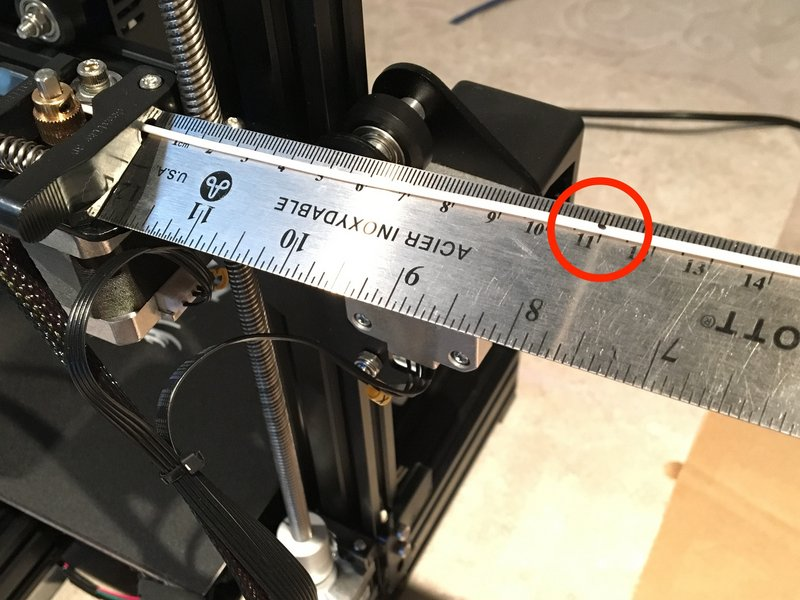

-For example...Here is a picture of my screen, this is what I'm running... and then these are the results of the execution of that specific setting on the screen.

For reference I put this 45mm(long end) Allen Key compared to the filament that came out. In maybe 30sec

Current E-steps while running this test

I really hope it's something stupid and obvious that I'm doing wrong or just not doing altogether, because I'm starting to worry. And, I mean.... I've just put so many hours into this build, ya know, and to have it be obliterated because of an e-step issue would be enough for me to just go back to my old board out of frustration. I just want to PRINT. Rant over. Sorry bout that, just had to get that out of my system.

Thanks,

-Carson

-

If I need to send a video file of what's happening, I will.

Oh, and here's what the screen of my PanelDue looks like during all this. It's like its not in sync with the DWC

-

You measure the filament going INTO the extruder, not out of it. You really need to look at that guide.

-

I did that first, initially. And at 93steps it went way past my line. I've calibrated printers before. My concern is when I run the same program 3 times and I get different results. I assume that when my black line disappears at a high speed at 93 steps and then keeps going, and going when I set it at a low speed, and the next time I run the same program it spits out nothing....that it's not extruding correctly. That coupled with the fact that my PanelDue says its extruding different values that my DWC is.

-

After the 8th time measuring out my black line, I stopped because there's no point to try and awkwardly get in there to measure it if I know its going to be wrong. That's when I started to look at how much was extruding out of the nozzle.