Hello Friends, I seem to have encountered an overshoot problem

-

After the 20mm*20mm square was printed, it seemed that there was an overshoot problem, which caused the square of the square to not be straight. Which parameter should I modify for this problem?

-

What type of printer is it?

-

Do you have pressure advance configured yet? Corner bulges can be tamed with pressure advance usually.

-

@dc42 My machine is Toolchanger

-

@phaedrux I haven’t configured pressure advance yet. Will this situation have something to do with acceleration?

-

Well yes, acceleration will play a part. So will jerk and overall print speed, but for the XYZ axis as well as extruder. It's all inter-related.

https://duet3d.dozuki.com/Wiki/Pressure_advance

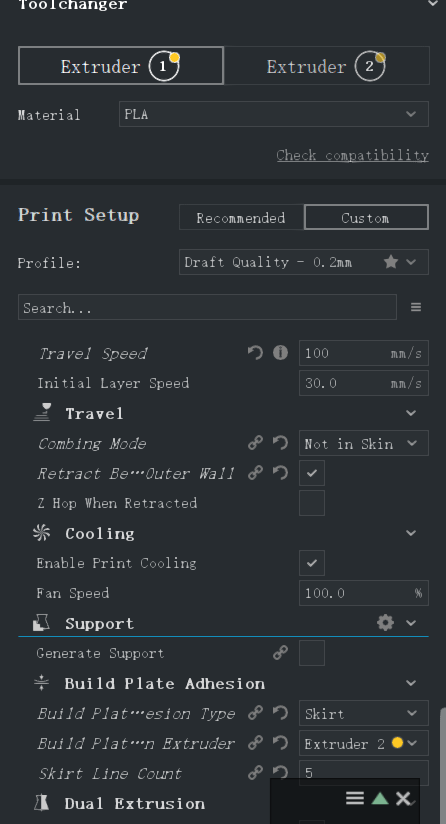

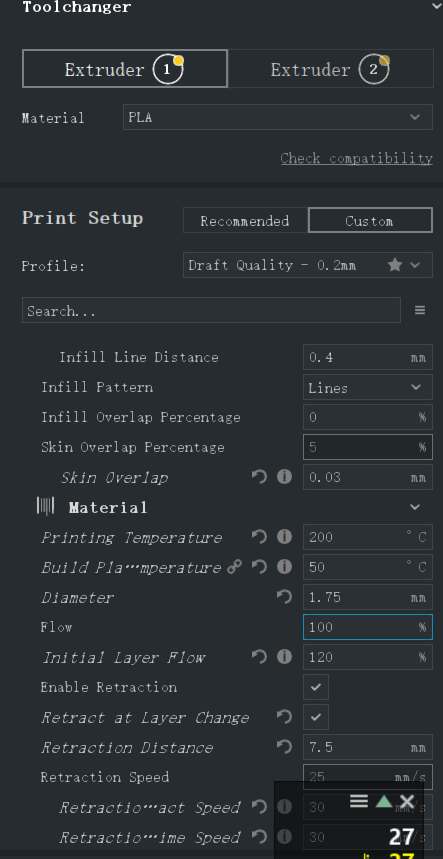

Post your config.g and print settings if you want more detailed suggestions.

-

-

What kind of a printer is it? E3D tool changer?

CoreXY tool changer, but what does it look like? Photo?

How heavy would you say the print head is with a tool loaded?

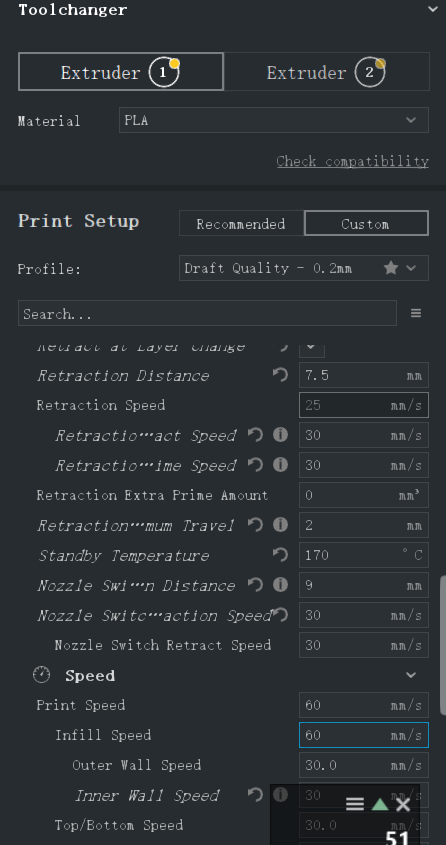

Direct drive or bowden extruder? A retraction distance of 7.5mm would indicate bowden. Have you tuned retraction yet?Your max print speed is also quite low.

M203 X3000 Y3000

Only 50mm/s which is half the speed you've set for travel moves. So you should at least set your max speed to match what you want to use for travels. M203 X6000 Y6000

On first glance I would say your jerk values are a bit low, meaning the print head will slow down on corners, which can make bulges at corners more pronounced.

M566 X300 Y300

Try M566 X900 Y900

If you are using a Bowden extruder start with a pressure advance value of M572 D0 S1 and see how it goes.