2nd independent Z-Axis labeled V Homing failed

-

Hi,

So I have two independent Z axis and X axis. when I home the X axis both carriages move towards the low end endstops and homes fine. When I home the Z axis both axis move and I have only bltouch 1 deployed and triggers homing succeeds. Then I home the V axis which is the 2nd Z axis with it's own bltouch this also deploys and triggers as it hits the bed. However there is a difference in behavior compared the the X axis the second X axis labeled U is the only one that moves and homes, but when homing V axis both Z axis move jointly the bltouch pertaining to that V axis triggers correctly and both Z axis stops moving but then I se a response G28 V Error Homing failed for the V axis with no error explanation. Not sure why both Axis move when homing V but when homing U only U axis moves the main X axis doesn't move I would expect the V axis to be the only one to move as well. I am including the config.g maybe there's something that I missed. The other question is do I really need to home V and U axis. I don't know yet how the concept of having 2 independent X and Z axis should behave, this Idea cam from watching the Zydex printer video. My thought is that with 2 independent Z and X axis the print job that would normally take 4 days would be cut in 1/2. So I really need to understand what is the purpose of having 2 dual independent Z and X axis.

-

@jsinicro forgot to include the config.g

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:09 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"jsinicro_1" ; set printer name ; Network M551 P"tinisa1125" ; set password M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; ; Drives S = motor direction 0 is backwards/reversed direction based on motor orientation ; M569 P0.0 S1 ; physical drive 0.0 goes forwards z xxis 1 motor 1 M569 P0.1 S1 ; physical drive 0.1 goes forwards z axis 2 motor 1 M569 P0.2 S1 ; physical drive 0.2 goes forwards y axis 1 motor 1 M569 P0.3 S1 ; physical drive 0.3 goes forwards y axis 1 motor 2 M569 P0.4 S1 ; physical drive 0.4 goes forwards z axis 2 motor 2 M569 P0.5 S1 ; physical drive 0.5 goes forwards z axis 1 motor 2 M569 P1.0 S1 ; physical drive 1.0 goes forwards x axis 2 motor 1 M569 P1.1 S0 ; physical drive 1.1 goes forwards x axis 2 tool 1 motor M569 P3.0 S0 ; physical drive 3.0 goes forwards x axis 1 motor 1 M569 P3.1 S0 ; physical drive 3.1 goes forwards x axis 1 tool 2 motor ; mapping 2 motors on separate X axis and 2 motors each on 2 separate Z axis Y has just 2 motors M584 X1.0:3.0 U3.0 Y0.2:0.3 Z0.0:0.5:0.1:0.4 V0.1:0.4 E1.1:3.1 p5 M350 X16 Y16 U16 Z16 V16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y320.00 U80.00 Z400.00 V400.00 E420.00:420.00 ; set steps per mm M566 X900.00 Y900.00 U900.00 Z60.00 V60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 U6000.00 Z180.00 V180.0 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 U500.00 Z20.00 V20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 U800 Z800 V800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 U0 V0 S1 ; set axis minima M208 X700 Y800 U700 Z800 V800 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!1.io0.in" ; configure 2 active-low "!" in name endstop for low end on X M574 Y1 S1 P"!1.io1.in" ; Y M574 Z2 S1 P"!1.io3.in" ; Z M574 V2 S1 P"!3.io3.in" ; Z M574 U1 S1 P"!3.io0.in" ; configure 2 active-low "!" in name endstop for low end on X ; Z-Probe M558 P9 C"^1.io4.in" H5 F120 K0 T6000 ; disable Z probe but set dive height, probe speed and travel speed M950 S0 C"1.io4.out" G31 X42 Y0 Z2.098 K0 P25 M558 P9 C"^3.io4.in" H5 F120 K1 1T6000 ; disable Z probe but set dive height, probe speed and travel speed M950 S1 C"3.io4.out" G31 X-44 Y0 Z2.098 K1 P25 ; Heaters ;M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 main board ;M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;M140 H0 ; map heated bed to heater 0 ;M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"1.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin and CAN #3.temp0 M950 H1 C"1.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"3.temp0" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin and CAN # 1.temp0 M950 H2 C"3.out0" T2 ; create nozzle heater output on 2.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans ;M950 F0 C"1.out3" Q500 ; create fan 0 on pin 1.out3 and set its frequency ;M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"1.out4" Q500 ; create fan 1 on pin 2.out3 and set its frequency ;M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ;M950 F2 C"3.out3" Q500 ; create fan 2 on pin 1.out4 and set its frequency ;M106 P2 S1 H1-1 T45 ; set fan 2 value. Thermostatic control is turned off ;M950 F3 C"3.out4" Q500 ; create fan 3 on pin 2.out4 and set its frequency ;M106 P3 S1 H1-1 T45 ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F2 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue -

Is there a specific need for the separated axis letters? In RRF3 you can home both X and Z motors as a single axis without splitting them up.

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

But maybe I don't understand the configuration of your printer. Does the Z axis have two endstops AND two BLtouch?

Please post your homing files as well.

-

@phaedrux said in 2nd independent Z-Axis labeled V Homing failed:

But maybe I don't understand the configuration of your printer.

It seems, he's using 2 Z-motors for the bed and another 2 for a 'mini Z-axis' on the 2nd tool? The same way I wanted to level both toolheads individually on my IDEY...

@jsinicro why do you use 0.1 & 0.4 steppers in both Z- and V-axis?

-

@jsinicro the standard G30 command can only be used to home the Z axis. To home another axis using a Z probe, try using G38.2. Use firmware 3.3RC2 because in older firmware versions G38 does not deploy/retract the probe. G38 is normally used with contact probes, so I don't know whether it will take the BLTouch trigger height into account.

-

@phaedrux thaniyou for the reply. I am not sure if I need independent Z and X axis, my thought was that by doing so I could extrude independently at the same time thus the model would be built in 1/2 of the time, maybe the firmware doesn't support this, I don't know. So far when I test the filament If I heat up one tool the other goes in standby so not sure if both tools can extrude at the same time, The slicing software would have to support this, not sure. Maybe the only benefit of having 2 extruders is to be able to extrude 2 color filaments at different times. Which is fine, I can always tie the 4 motors of the Z and the 2 X motors to the same axis thus do away with U,V. I don't know. If you think about it if the slicing software could slice a model so that 2 or n extruders can work simultaneously with out hitting eachother that will be awesome.

here are my homing files:

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 X50 Y50 Z5 F6000 ; lift Z relative to current position G30 K1 ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z10 F100 ; lift Z relative to current position G90 ; absolute positioning; homev.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H1 X50 Y50 V5 F6000 ; lift Z relative to current position G30 K0 ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 V10 F100 ; lift Z relative to current position G90 ; absolute positioning; homeu.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 U-705 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 H2 U5 F6000 ; go back a few mm G1 H1 U-705 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 X5 F6000 G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-705 F1100 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-705 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-705 F1100 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-705 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 X5 F6000 G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning -

@o_lampe I shouldn't be, maybe that's my mistake, 0.1 and 0.4 should be 2 motors on one Z axis and 0.0 and 0.5 should be on the V axis or vice versa but not mixed. thankyou for catching that.

-

@dc42 OK, I will try that, I am currently using G30 for both but with different tools K0, K1. OK I have RRF 3.2.2 on all 3 boards the doc says 3 and later, but will test.

-

@jsinicro looks like it is correct :

M584 X1.0:3.0 U3.0 Y0.2:0.3 Z0.0:0.5:0.1:0.4 V0.1:0.4 E1.1:3.1 p5Z0.0:0.5:0.1:0.4 these 4 motors for both Z axis. Driver0 and 5 on main 6HC then a ":" 0.1:0.4 these are for the 2nd Z axes called V so then V0.1:0.4 has the other 2 motors on driver1,4 on 6Hc. That was my interpretation of the M584. I think in my opinion these G-code commands are hard to interpret meaning: the exact syntax. is there a parsing grammar associated with it or BNF grammar.

Maybe in the above command for Z all i need is the 0.0:0.5 but the X axis is defined in the same manner and both X and U home successfully.

-

@jsinicro G38.2 P0 doesn't deploy the bltouch.

-

@jsinicro I've separated the M584 X and Z axis to:

M584 X1.0 U3.0 Y0.2:0.3 Z0.0:0.5 V0.1:0.4 E1.1:3.1 p5Each axis now homes individually except for the V axis the bltouch will not deploy using the G38.2 P0 command with RRF 3.2.2

I tried G30 K0 and the probe deployed on the V axis but the Z axis moved down instead the V axis did not move down.

if I do G28 V it doesn't deploy nor move down.

Looks like I can deploy both bltouch probes if I combine all motors to the Z axis but so far can't deploy the V axis with its own bltouch.

-

@jsinicro said in 2nd independent Z-Axis labeled V Homing failed:

@jsinicro G38.2 P0 doesn't deploy the bltouch.

See my previous response.

-

@dc42 Yes, I was confirming what you said that in 3.2.2 it will not deploy the blotouch. I was looking on how to upgrade from 3.2.2 to 3.3RC2 however I was not sure on how to do the upgrade with out building the binaries, then I found this link https://github.com/Duet3D/RepRapFirmware/releases/tag/3.3RC2 which lists all the .bin files and others, so looks like I will need to download all individual files one at a time, or will it be easier to connect to an SBC in my case raspberry pi 4, which is what I used to upgrade to 3.2.2, but still you mention that you're not sure if it will take the trigger height into account. I've decided to combine all motors to just the X, and Z axis and get rid of the U, V and test it out everything is working except the X axis when homing is moving in the opposite direction of where the endstops are located not sure why. I tried to configure M574 with X1 and X2 parameters but it always moves away from the endstops. Not sure what to do here.

-

@jsinicro said in 2nd independent Z-Axis labeled V Homing failed:

I tried to configure M574 with X1 and X2 parameters but it always moves away from the endstops. Not sure what to do here.

You control the direction of movement in the homing files. The M574 just defines if the endstop is at low or high end. It's up to you do set the direction towards the endstop in the homing files.

-

@phaedrux do you have a link on how to do that

homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-705 F1100 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-705 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 X5 F6000 G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioningDo I need to change this line: G1 H1 X-705 F1100 to G1 H1 X705 F1100

thx -

@jsinicro But that would mean that the positive X axis is in the reverse direction as it was before

-

The G1 H1 X move being positive or negative moves it to the low or high end.

The actual direction of travel is dictated by the direction of the rotation of the motor itself defined by M569 S0/S1.

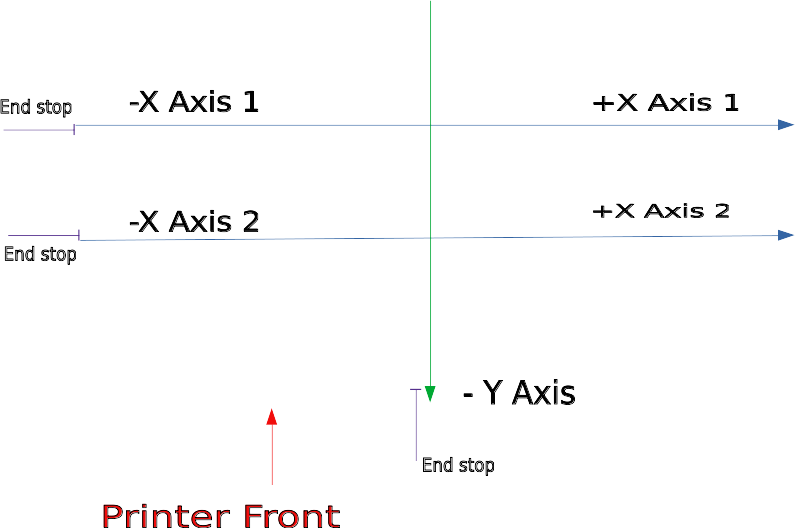

Typically you'd want it configured such that 0,0 is in the front left corner when looking at the printer from the front with -x moving to the left, +x moving to the right, -y moving to the front, +y moving to the back. This maintains a coordinate system compatible with CAD and slicing software and keeps the preview matching the actual print with no mirroring or flipping.

In a Corexy it gets a bit more complicated because of the shared motion between 2 motors in tandem. https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareCoreXYPrinter#Section_Testing_motor_movement

-

@phaedrux yes this is what I have:

-

@jsinicro it was moving correctly before, but now when I move +X it moves towards the negative X and when I home it moves towards the +X direction away from the endstops.

-

@jsinicro

There is another way to screw up the printing directions, when you set a custom kinematics model.

Do you have such a line in your config.g?Example:

M669 K1 X1:1:0:0 Y1:-1:0:1 Z0:0:1:0 V0:0:0:-1The positive and negative signs can change the whole printer behaviour.