3HC CAN stopped connecting

-

Everything was working well, until it wasn't...

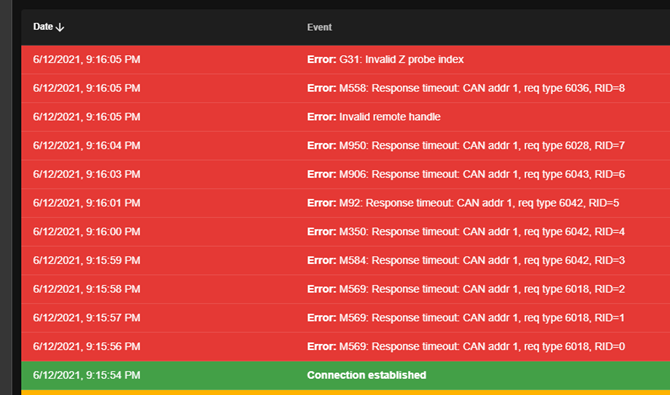

I built a 3D printer using the 6HC and 3HC and was in the process of working through getting it dialed in. After an unsuccessful test, I went to level the bed again and the Z axis did not respond and threw numerous CAN bus errors. Now when I look at the 3HC, the DIAG LED is not longer flashing at all. It doesn't seem to even see the board any more. They were both running 3.2.2. When I restart the 6HC I get the following errors

All of the power LEDs on the 3HC are lighting, as usual, just no sync with the 6HC. When I run the Diagnostics, under the System > Machine-Specific tab, I get the following:

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956L2-G43S8-6J1DG-3S46M-KV2YD Used output buffers: 1 of 40 (12 max) === RTOS === Static ram: 149788 Dynamic ram: 63500 of which 48 recycled Never used RAM 145496, free system stack 200 words Tasks: Linux(ready,101) HEAT(blocked,297) CanReceiv(blocked,927) CanSender(blocked,371) CanClock(blocked,352) TMC(blocked,53) MAIN(running,1149) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:09:05 ago, cause: power up Last software reset details not available Error status: 0x00 Aux0 errors 0,0,0 Aux1 errors 0,0,0 MCU temperature: min 39.7, current 42.4, max 42.6 Supply voltage: min 24.1, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.2, current 12.2, max 12.2, under voltage events: 0 Driver 0: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available Driver 1: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available Driver 2: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available Driver 3: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available Driver 4: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available Driver 5: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available Date/time: 2021-06-12 22:08:49 Slowest loop: 0.45ms; fastest: 0.04ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === CAN === Messages queued 1833, send timeouts 4124, received 0, lost 0, longest wait 0ms for reply type 0, free buffers 48 === SBC interface === State: 4, failed transfers: 0 Last transfer: 0ms ago RX/TX seq numbers: 17939/17939 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2c8a8 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.2 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 34.80 Maximum length of RX/TX data transfers: 3039/708Help!

My config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; ***** Drives ***** ; 6HC Main Board M569 P0.0 S0 ; physical drive 0.0 goes reverse - Right Y Axis M569 P0.1 S0 ; physical drive 0.1 goes reverse - X Axis Hotend M569 P0.2 S1 ; physical drive 0.2 goes forwards - Left Y Axis M569 P0.3 S1 ; physical drive 0.3 goes forward - Left Extruder M569 P0.4 S0 ; physical drive 0.4 goes reverse - U Axis Hotend M569 P0.5 S1 ; physical drive 0.5 goes forwards - Right Extruder ; 3HC Expansion Board M569 P1.0 S1 ; physical drive 1.0 goes forwards - Z Axis Front-Left M569 P1.1 S1 ; physical drive 1.1 goes forwards - Z Axis Back-Center M569 P1.2 S1 ; physical drive 1.2 goes forwards - Z Axis Front-Right M584 X0.1 Y0.0:0.2 Z1.0:1.1:1.2 U0.4 E0.3:0.5 ; set drive mapping M350 X16 Y16 Z16 U16 E16:16 I1 ; configure microstepping with interpolation M92 X40.00 Y80.00 Z1600.00 U40.00 E400.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 U900.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z1000.00 U12000.00 E1800.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 U500.00 E250.00 ; set accelerations (mm/s^2) M906 X1500 Y1500 Z1500 U1500 E300 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 U45 S1 ; set axis minima M208 X370 Y400 Z380 U411 S0 ; set axis maxima ; Z leadscrew locations M671 X-60:197.5:480 Y-30:425:-30 S10 ; three leadscrews at Front-Lft, Back-Center, and Front-Right ; Endstops M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y2 S1 P"io2.in+io1.in" ; configure active-high endstop for high end on Y via pin io1.in M574 U2 S1 P"io3.in" ; configure active-high endstop for high end on U via pin io1.in ; Z-Probe M950 S0 C"1.io1.out" M558 P9 C"1.io1.in" F200 H5 R0 T6000 A5 S0.03 B1 ; set Z probe type to switch and the dive height + speed G31 P25 X-13 Y0.0 Z0.75 ; set Z probe trigger value, offset and trigger height M557 X50:350 Y0:400 S50 ; define mesh grid ; ***** Heaters ***** ; Bed M308 S0 P"temp0" Y"thermistor" A"Bed Temp" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.601 C403.2 D5.29 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Left Hotend (X) M308 S1 P"temp1" Y"thermistor" A"Left Temp" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.392 C206.4 D5.67 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Right Hotend (U) M308 S2 P"temp2" Y"thermistor" A"Right Temp" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 R2.132 C230.6 D5.30 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; ***** Fans ***** ; Left Fan (X) M950 F0 C"out7" Q1000 ; create fan 0 on pin out7 and set its frequency M106 P0 S1 H1 T45 ; set fan 0 value. Thermostatic control is turned on ; Right Fan (U) M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H2 T45 ; set fan 1 value. Thermostatic control is turned on ; ***** Tools ***** ; Left Tool (X) M563 P0 S"Left" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Right Tool (U) M563 P1 S"Right" D1 H2 X3 F1 ; define tool 1 G10 P1 X45 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Dual Tools M563 P2 S"Dual" D0:1 H1:2 X0:3 F0:1 G10 P2 X100 Y0 U-100 S0 R0 M567 P2 E1:1 M150 X0 ; Miscellaneous T0 ; select first tool -

Edit:

After more digging into the issue, it appears not ALL power LEDs are lit. The Green 3.3V LED is not on. When I check the 3.3V probe point with a multimeter, I'm only getting .022v... What would cause the 3.3v to crap out like that? Would that impact the CAN bus? I'm assuming the Atmel microprocessor runs off the 3.3v supply. Is there a way to fix that other than scrapping the board? -

@vbuys is anything connected to the 3HC other than VIN and CAN ?

-

@dc42 only my 3 Z steppers and a BLTouch on IO_1.

-

Can you add a G4 S5 near the beginning of your config.g to allow time for the 3HC to come up?

What does M122 B1 report?

-

@phaedrux thanks for the suggestion. I added the G4 S5, but no change.

M122 B1 reports :

Error: M122: Response timeout: CAN addr 1, req type 6024, RID=9

-

@vbuys said in 3HC CAN stopped connecting:

@dc42 only my 3 Z steppers and a BLTouch on IO_1

Try disconnecting the BLTouch and see whether the 3.3V LED lights up then.

-

@dc42 I tried with the BLTouch disconnected, as well as with the BLTouch and all steppers disconnected, but neither scenario made any difference and the 3.3v LED remains off.

-

It's likely that something has failed on the 3HC if the 3.3v LED remains off and should be replaced under warranty.

Please send an email to warranty@duet3d.com and CC your reseller. Include a link to this forum thread and the details of your original purchase. You'll receive a reply with a form to fill out.

Sorry for the inconvenience.

-