Everything was working well, until it wasn't...

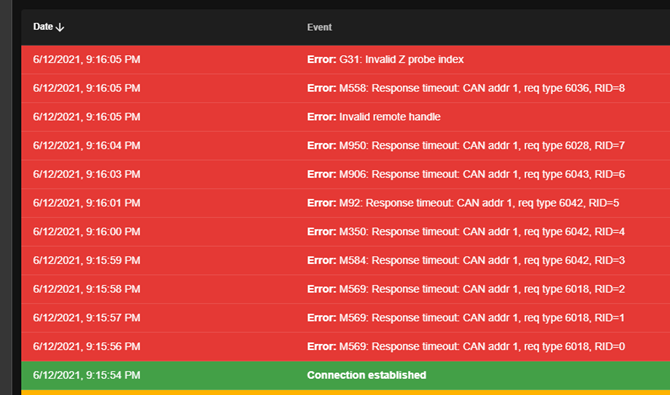

I built a 3D printer using the 6HC and 3HC and was in the process of working through getting it dialed in. After an unsuccessful test, I went to level the bed again and the Z axis did not respond and threw numerous CAN bus errors. Now when I look at the 3HC, the DIAG LED is not longer flashing at all. It doesn't seem to even see the board any more. They were both running 3.2.2. When I restart the 6HC I get the following errors

All of the power LEDs on the 3HC are lighting, as usual, just no sync with the 6HC. When I run the Diagnostics, under the System > Machine-Specific tab, I get the following:

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (SBC mode)

Board ID: 08DJM-956L2-G43S8-6J1DG-3S46M-KV2YD

Used output buffers: 1 of 40 (12 max)

=== RTOS ===

Static ram: 149788

Dynamic ram: 63500 of which 48 recycled

Never used RAM 145496, free system stack 200 words

Tasks: Linux(ready,101) HEAT(blocked,297) CanReceiv(blocked,927) CanSender(blocked,371) CanClock(blocked,352) TMC(blocked,53) MAIN(running,1149) IDLE(ready,19)

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:09:05 ago, cause: power up

Last software reset details not available

Error status: 0x00

Aux0 errors 0,0,0

Aux1 errors 0,0,0

MCU temperature: min 39.7, current 42.4, max 42.6

Supply voltage: min 24.1, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.2, current 12.2, max 12.2, under voltage events: 0

Driver 0: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available

Driver 1: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available

Driver 2: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available

Driver 3: position 0, standstill, reads 34239, writes 0 timeouts 0, SG min/max not available

Driver 4: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available

Driver 5: position 0, standstill, reads 34238, writes 0 timeouts 0, SG min/max not available

Date/time: 2021-06-12 22:08:49

Slowest loop: 0.45ms; fastest: 0.04ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 1833, send timeouts 4124, received 0, lost 0, longest wait 0ms for reply type 0, free buffers 48

=== SBC interface ===

State: 4, failed transfers: 0

Last transfer: 0ms ago

RX/TX seq numbers: 17939/17939

SPI underruns 0, overruns 0

Number of disconnects: 0, IAP RAM available 0x2c8a8

Buffer RX/TX: 0/0-0

=== Duet Control Server ===

Duet Control Server v3.2.2

Code buffer space: 4096

Configured SPI speed: 8000000 Hz

Full transfers per second: 34.80

Maximum length of RX/TX data transfers: 3039/708

Help!

My config.g

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

; ***** Drives *****

; 6HC Main Board

M569 P0.0 S0 ; physical drive 0.0 goes reverse - Right Y Axis

M569 P0.1 S0 ; physical drive 0.1 goes reverse - X Axis Hotend

M569 P0.2 S1 ; physical drive 0.2 goes forwards - Left Y Axis

M569 P0.3 S1 ; physical drive 0.3 goes forward - Left Extruder

M569 P0.4 S0 ; physical drive 0.4 goes reverse - U Axis Hotend

M569 P0.5 S1 ; physical drive 0.5 goes forwards - Right Extruder

; 3HC Expansion Board

M569 P1.0 S1 ; physical drive 1.0 goes forwards - Z Axis Front-Left

M569 P1.1 S1 ; physical drive 1.1 goes forwards - Z Axis Back-Center

M569 P1.2 S1 ; physical drive 1.2 goes forwards - Z Axis Front-Right

M584 X0.1 Y0.0:0.2 Z1.0:1.1:1.2 U0.4 E0.3:0.5 ; set drive mapping

M350 X16 Y16 Z16 U16 E16:16 I1 ; configure microstepping with interpolation

M92 X40.00 Y80.00 Z1600.00 U40.00 E400.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 U900.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z1000.00 U12000.00 E1800.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 U500.00 E250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z1500 U1500 E300 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 U45 S1 ; set axis minima

M208 X370 Y400 Z380 U411 S0 ; set axis maxima

; Z leadscrew locations

M671 X-60:197.5:480 Y-30:425:-30 S10 ; three leadscrews at Front-Lft, Back-Center, and Front-Right

; Endstops

M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in

M574 Y2 S1 P"io2.in+io1.in" ; configure active-high endstop for high end on Y via pin io1.in

M574 U2 S1 P"io3.in" ; configure active-high endstop for high end on U via pin io1.in

; Z-Probe

M950 S0 C"1.io1.out"

M558 P9 C"1.io1.in" F200 H5 R0 T6000 A5 S0.03 B1 ; set Z probe type to switch and the dive height + speed

G31 P25 X-13 Y0.0 Z0.75 ; set Z probe trigger value, offset and trigger height

M557 X50:350 Y0:400 S50 ; define mesh grid

; ***** Heaters *****

; Bed

M308 S0 P"temp0" Y"thermistor" A"Bed Temp" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.601 C403.2 D5.29 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

; Left Hotend (X)

M308 S1 P"temp1" Y"thermistor" A"Left Temp" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 R2.392 C206.4 D5.67 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Right Hotend (U)

M308 S2 P"temp2" Y"thermistor" A"Right Temp" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 R2.132 C230.6 D5.30 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C

; ***** Fans *****

; Left Fan (X)

M950 F0 C"out7" Q1000 ; create fan 0 on pin out7 and set its frequency

M106 P0 S1 H1 T45 ; set fan 0 value. Thermostatic control is turned on

; Right Fan (U)

M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency

M106 P1 S1 H2 T45 ; set fan 1 value. Thermostatic control is turned on

; ***** Tools *****

; Left Tool (X)

M563 P0 S"Left" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Right Tool (U)

M563 P1 S"Right" D1 H2 X3 F1 ; define tool 1

G10 P1 X45 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Dual Tools

M563 P2 S"Dual" D0:1 H1:2 X0:3 F0:1

G10 P2 X100 Y0 U-100 S0 R0

M567 P2 E1:1

M150 X0

; Miscellaneous

T0 ; select first tool