Found issues using duet as CNC controller

-

@pcr let me look into this things now

-

@pcr said in Found issues using duet as CNC controller:

@jrentschler01

The CNC is now in DWC 3.4 Beta 5. You have to Just Install it. You Always have to Install the RRF and Same DWC VersionG68 is Just implemented. But still Testing.

Live coordinates you can See with the DWC CNC

I tryed the DWC3.4 Beta 5 as well.. the same no CNC Conrols visible nowhere:

(I'm using the M453 in the config.g)

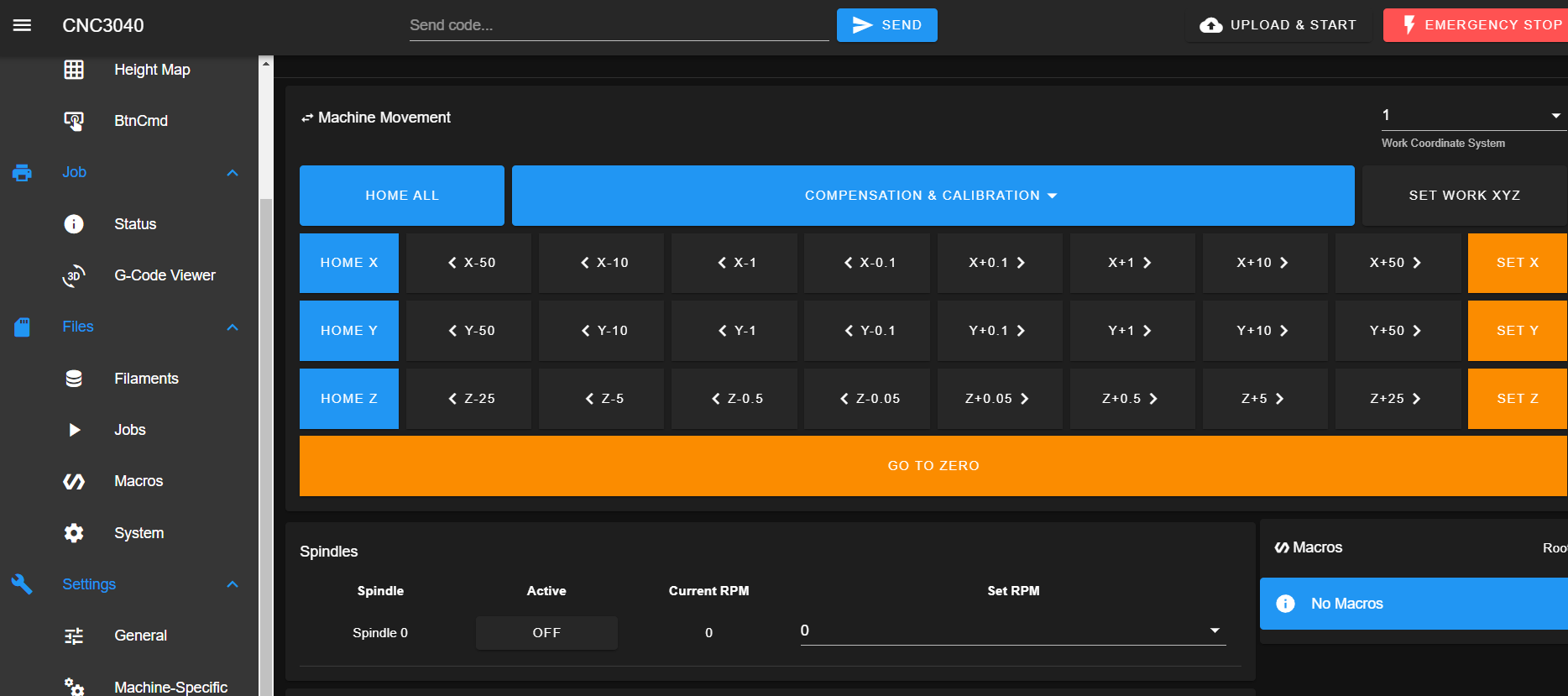

At DWC 3.3.-CNC08 they are visible:

Btw I use Chrome as Browser.

-

@jrentschler01 try Clearing the Cache and reboot DWC. I once Had the Problem aswell.

-

@jrentschler01 you can choose the CNC from the settings. Try toggle IT.

-

@pcr I already cleared the cache and also tryed it in edge, when it is loading you can see for a sec the printer conrols then they disapear. Thats it

you can choose the CNC from the settings. Try toggle IT.

Where which setting do you mean?

-

@pcr said in Found issues using duet as CNC controller:

Try using

G10 L2 P1 X50 Y50

Then G54

Okay you right I was missing G54, so this is solved now. Thank you!

-

@pcr said in Found issues using duet as CNC controller:

stopping can be quick If you Play with the segment paramter

can you tell me a bit more about that? or tell me where this is documented?

-

@jrentschler01 add something like

M669 K0 T1 S1

That should do -

@jay_s_uk okay did it:

5.11.2021, 19:38:57 M669

Kinematics is Cartesian, 1 segments/sec, min. segment length 1.00mm, matrix:

1.00 0 0

0 1.00 0

0 0 1.00I'm not exactly sure what itr should do? I read the documentation and I guess it helps if more Movement commands in the buffer but if you have an long onging movement like 100mm it sill will not stop until this is done. I tryed it with M0

-

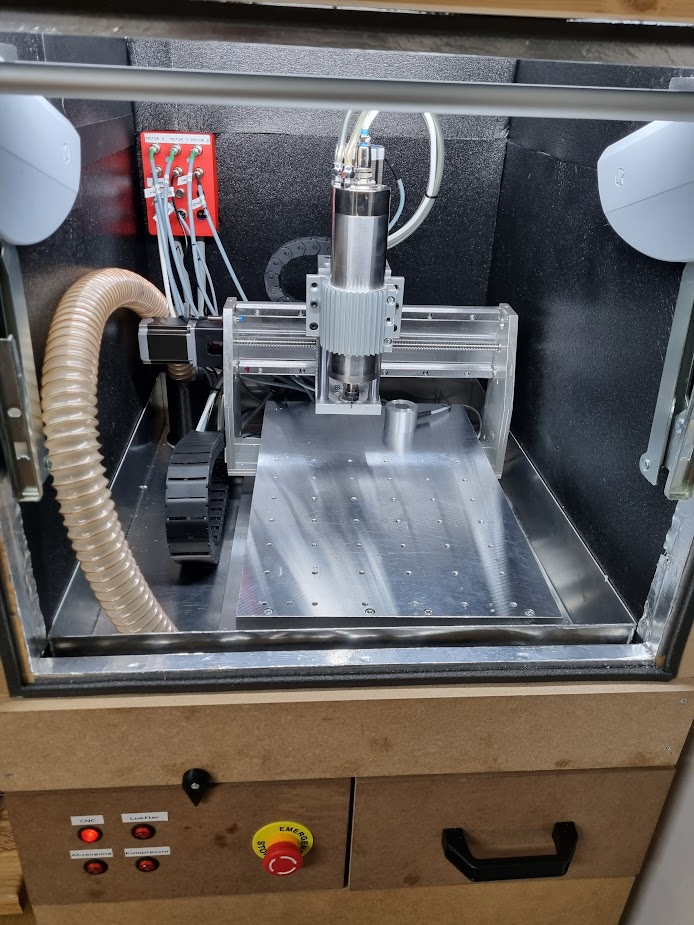

just for who is curious wht kind of CNC I have here a picture to have idea of it:

It's nothing Special, but it works precise and fine with milling aluminium. The Axis motors could be a bit bigger to go faster, but thats fot the next step.

-

@jrentschler01 said in Found issues using duet as CNC controller:

but if you have an long onging movement like 100mm it sill will not stop until this is done. I tryed it with M0

M0 will wait until all existing moves are complete. Try a pause command instead. If the movement speed is lower than the jerk configured using M566, it should pause between segments.

-

@dc42 I'm getting close to finishing up my Duet 2 wifi based CNC and reading this post has me a tad concerned about the pause command. The machine I'm building has 2500mm length in Y and 1250mm in X. My intended use is to make large cabinet parts and I could see the need to have a stop in the middle of a very long straight move. Is there not provision to stop the movement mid move? I run a run a UCCNC based router at work and there is a feed pause command which will just stop movement immediately which is extremely handy when you need to pause the feed during a travel move or any move where there is no contact with the workpiece. There are times you might need to move a clamp that is in the way of a travel move so hitting "pause feed" is very handy. Then you can resume the feed which will just resume the feed.

I think it would be helpful to have both the conventional pause that is already there which calls the pause.g macro (very handy in 3D printing) and then using the resume.g macro to get back to where you were and start again. But then have a seperate feed hold or feed pause which just pauses the current move and then resumes that same move right where it left off. No macro call just a simple interrupt/pause of the signals going to the stepper drivers.

-

@baird1fa if you set small segment values (e.g. M669 S1 T1) you can pause virtually straight away and then resume where you've left off

-

@jay_s_uk so are the segment values something that the duet firmware uses to break the moves into smaller pieces? Is there a downside to doing that?

-

@baird1fa that's correct.

And none that I've seen at the speeds we'll be cutting at