Is a 1ftx1ftx2ft build volume doable with a hotbed?

-

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

Since I'm doing a custom build, I figured I'd at least look into a 1x1x2 volume. Will this work with a hotbed, or am I better off just building a delta later?

What kind of printer are you thinking about?

That build volume is certainly feasible though you would likely want to adjust the 1 x 1 to use commonly available components. For example a 300mm x 300mm KEENOVO bed heater mounted to a 320mm x 320mm aluminum plate. There are several similar sizes you could chose from like the 310mm x 310mm unit designed for a Creality CR-10.

Frederick

-

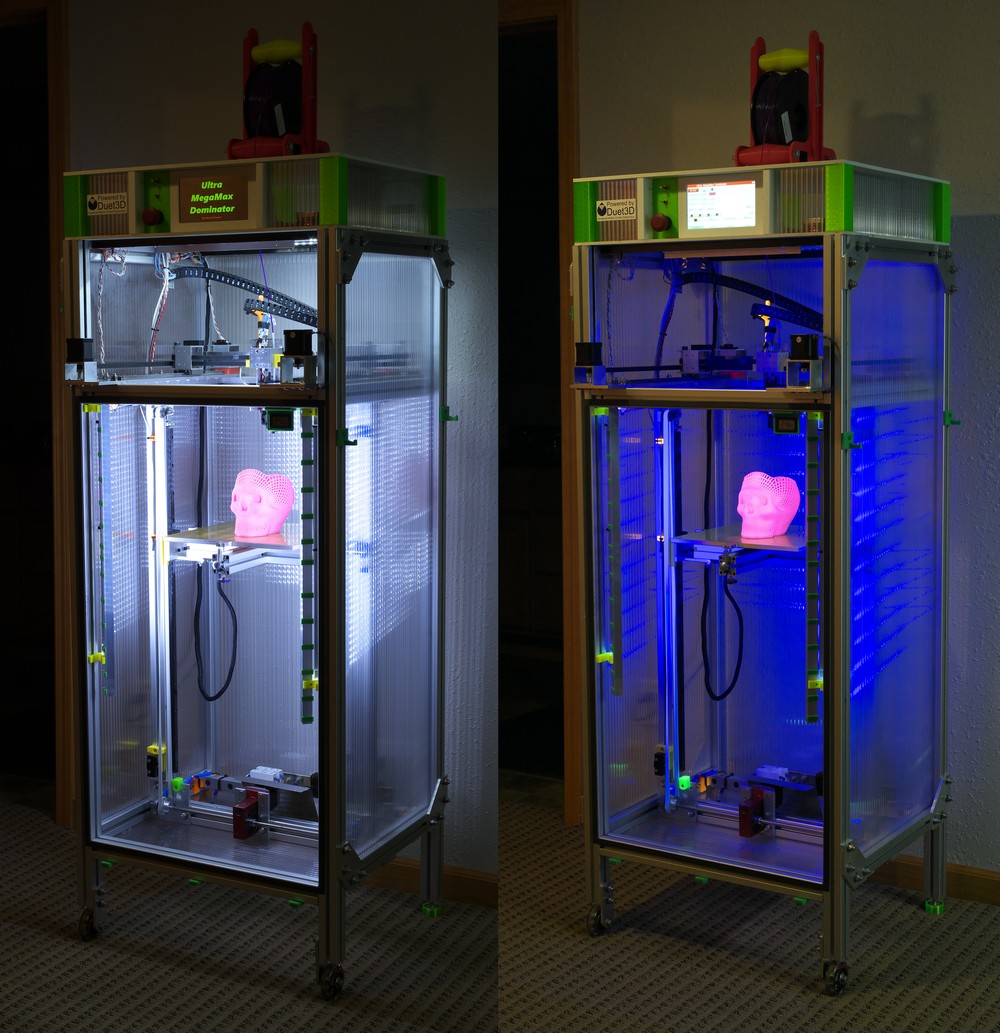

@virgosystems My corexy machine has 300x300 x 690 mm build volume, so yes, it can be done. I used a Keenovo 300x300 mm 750 W line powered heater on a cast aluminum plate bed. The bed is the same size as the heater, except for some ears where the leveling screws sit. If you use a plate that's larger than the heater you risk bowing when the bed is heated because the edges will be much cooler than the heated center. The bed plate sits on a kinematic mount that allows it to expand without forcing anything to flex.

The tricky part for that long Z axis is keeping it stable so print quality is maintained from the bed plate all the way up. I used belts to lift the Z axis on linear guides instead of lead screws that may tend to wobble, especially as they get longer. The belts stretch a tiny bit, but not enough to matter. I drive the Z axis with a single motor and a 30:1 worm gear reducer so the bed doesn't move when power is lost and never tilts upon power up.

My printer does not use auto tramming- it's not needed - which keeps things very simple and reliable. I only have to re tram the bed if I take the Z axis apart for some reason. The last time was about a year ago. RRF's manual bed leveling assistant works well so re tramming takes about one minute and only requires adjusting two screws.

-

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

Since I'm doing a custom build, I figured I'd at least look into a 1x1x2 volume. Will this work with a hotbed, or am I better off just building a delta later?

I like delta printers; however in order to print 2m high on a 1m diameter delta the total height of the printer would need to be around 3.4m. Too tall for most domestic settings but perhaps OK in a factory. Here's as example that uses Duet electronics: https://tractus3d.com/products/t3500/.

If you don't have that height available then a CoreXY design would be more suitable.

-

@virgosystems Yes, perfectly possible. My CoreXYUVAB has a build volume a tad under 400mm X 400mm X 800mm. Like @mrehorstdmd , I don't use any form of firmware flatness or leveling but my build platform is driven by a more conventional 3 lead screw/ single motor arrangement.

-

@mrehorstdmd I asked this elsewhere, but where do you recommend going for mechanical parts? I'm getting most of the electronics from matterhackers but they don't even have framing.

-

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

@mrehorstdmd I asked this elsewhere, but where do you recommend going for mechanical parts? I'm getting most of the electronics from matterhackers but they don't even have framing.

You can find many sources of aluminum extrusions - just do a google search.

I've gotten mine from different places including Amazon.

I get my steppers from STEPPERONLINE which can also be found on Amazon.

Frederick

-

@fcwilt well I was referring specifically to the smaller stuff - bolts etc

-

@mrehorstdmd you didn't end up with anything like a BOM, perchance?

-

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

@fcwilt well I was referring specifically to the smaller stuff - bolts etc

I get my hardware like that from Amazon. They have assortments of common metric sizes - 2.0 / 2.5 / 3.0 / 4.0 / 5.0 and 6.0 if you need something that robust.

RTL Fasteners has a good selection of items as well.

I use both socket head and button head styles.

Frederick

-

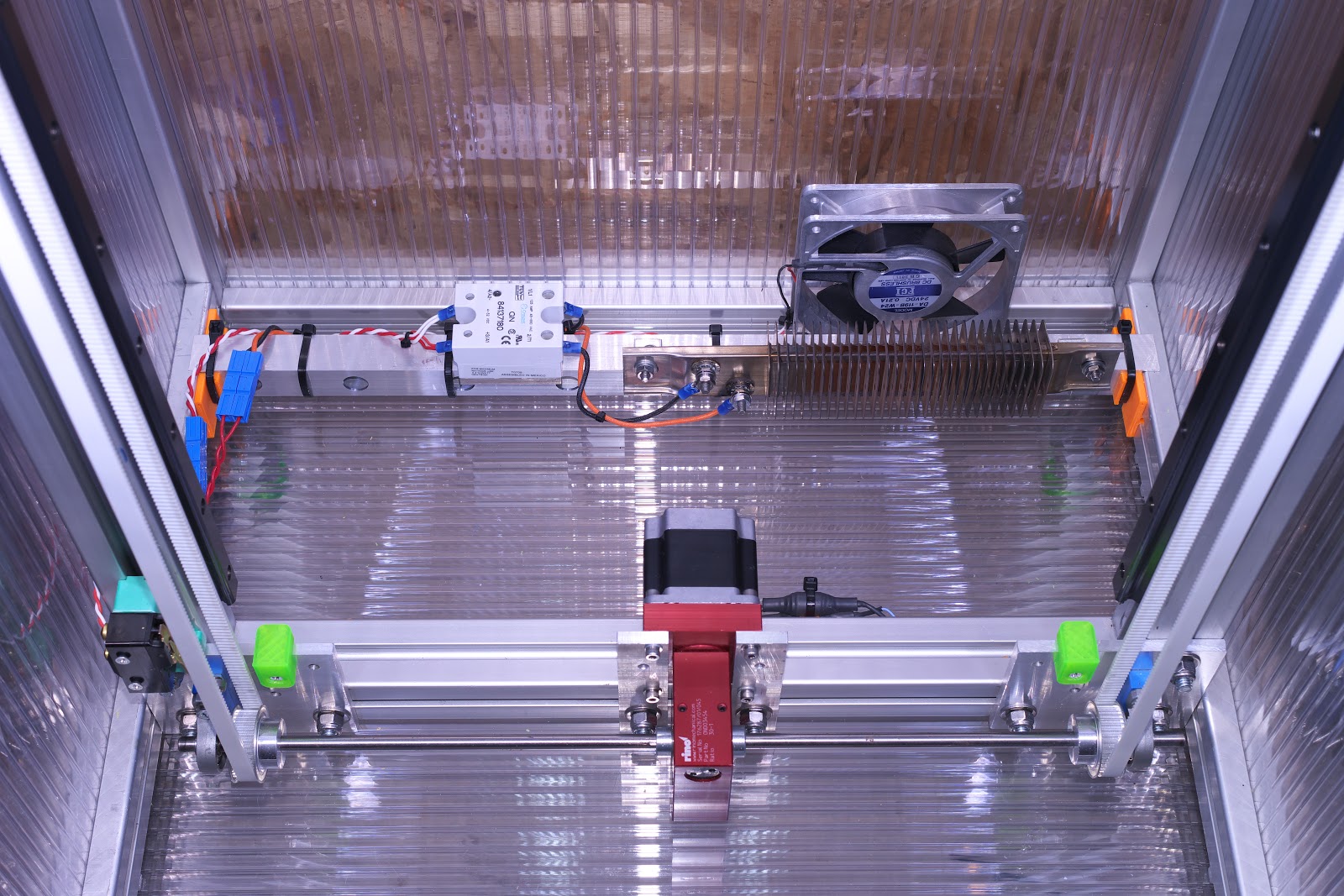

@mrehorstdmd btw, what's that on the floor? Just motors?

-

@virgosystems Misumi has t-slot at reasonable rates and from what I hear, their cuts are square and accurate length. I buy t-slot at a couple local scrap yards for scrap aluminum price.

I buy quality linear guides via ebay- not Hi-Win knockoffs, but brands like IKO, Thomson, Bosch, etc. Hi-Win makes good guides, but their numbering scheme has been copied by dozens of factories in China that make poor quality parts, so unless you buy from a Hi-Win dealer, I'd stay away from anything with a MGN type part number.

This is the Z axis motor/gearbox I used: https://www.ebay.com/itm/191714031261?epid=711126295&hash=item2ca30bf69d:g:A7UAAOSwPhdVB2f0

For $108 you get the motor and the best quality gears you'll ever find for the cost of a motor plus brake (and a lot of screwing around to get the brake working). The advantage of the geared mechanism is that the bed absolutely will not move when power is lost, and you can move a very heavy bed assembly with it, and there's no special configuration required- just set steps per mm and microstepping and you're done. With the pulleys I am using I get 20 um per full step of the motor, so I use layer thicknesses that are multiples of 20 um. I have measured belt stretch with glass and steel core belts and it is inconsequential in both cases.I used 40x40 t-slot for the frame with some fore/aft corner bracing. The side panels are dual layer polycarbonate of the sort used for making greenhouses. It provides thermal insulation and lets light through, but does not help to stiffen the printer's frame. Sheets of almost any rigid material screwed to the sides of the enclosure would provide increased rigidity. The front doors are made of clear polycarbonate sheet, the lower one held on the frame with magnetic tape, the upper one slides up/down in the slots in the t-slot frame.

The t-slot I used has 8mm wide slots, so I was able to use cheap 5/16" carriage bolts to hold some of the parts together. I used t-nuts in some places, ordered via ali-express. I think I ordered some other hardware through amazon.com.

I never made a BOM, mostly because it's unlikely that others would be able to get the exact parts I used and it was enough trouble to build the machine without trying to document it in that much detail. You'll notice that my CAD files lack many of the nuts and bolts that hold the machine together.

In the bottom of the printer you're seeing the red gearbox/motor at the center, and just behind them is the SSR that switches power to the chamber heater. There's a single 8mm shaft through the gearbox that drives pulleys/belts on the right and left sides of the machine. There is also a piece of sheet steel mounted on the back of the motor to deflect the warm air blowing over the chamber heater.

More on the machine here.

There have been many updates to the original design which can be found in different posts- search the blog for "UMMD". -

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

1x1x2 volume

Have you considered starting with a Voron V2.4 and stretching it in the vertical direction? It uses belts for Z movement so should be easier than stretching rods, and because the the gantry moves in z direction, you will have a lower center of gravity and better stability.

-

@zapta a little pricier than I wanted but worth a look. Besudes, wouldn't modifications void the warranty?

-

@mrehorstdmd oh the cad files are a massive help. Thanks so much.

-

@virgosystems said in Is a 1ftx1ftx2ft build volume doable with a hotbed?:

Besudes, wouldn't modifications void the warranty?

Vorons are built from self sourced parts and from kits. I there is any warranty, I don't think it will be affected.

You can try the Voron V2.4 configurator. Select custom and enter the Z value you want.

-

@mrehorstdmd how much spare time do you have? I have a business proposal you may find interesting.

-

This post is deleted! -

@mrehorstdmd sent