Steppers Grinding/Jerking On Arcs

-

Hi there,

I've been trying to solve this for a while now, but I have now idea why it is happening. I have a Duet 2 WiFi from around 2019 (latest firmware) and for a while now I've had issues with printing arcs/circles/anything curved in that the steppers jerk/grind/resonate the whole printer. It has no issues printing straight sections, so pretty sure it's not a mechanical issue (e.g. loose belts or crap rails). I've also tried different steppers, but no joy.

Printing a test file highlights results of the jerky motion. It's a bit out of focus, but I think it shows the issue well enough.

I've also taken a video of the print to demonstrate the effect of the jerky motion/resonance.

The issue also does not present itself when printing at (significantly) lower speeds.

Any help would be very much appreciated!

Cheers

-

Post your config.g and perhaps a sliced gcode file so we can see the settings.

-

-

@dzg7pl from your config.g:

M566 X150 Y150 Z12 E9000 P1 ; Set maximum instantaneous speed changes (mm/min)

That's a very low setting, which will likely cause printing to slow down and print at an uneven speed when printing curves. Try increasing the X and Y values to 600.

-

@dc42 That was it!

I had to up it to 2000 to completely remove the issue.

I had to up it to 2000 to completely remove the issue.Thank you so much

-

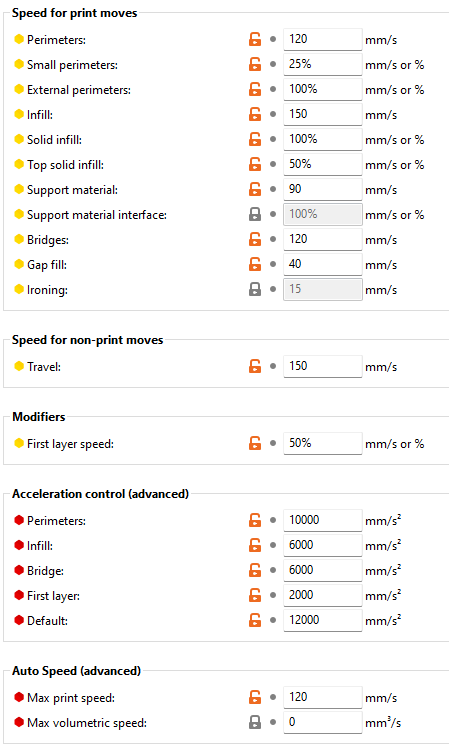

@dzg7pl this seems a bit excessive in the other direction imho. Curious what your acceleration and speed settings are.

-

Bit embarrassed to post that TBH

-

@dzg7pl no need to be embarrassed, but thay 10k acceleration on perimeters vs 6k on infill does look a bit weird. If you can do 10k perimeters without ringing then you can go full blast on infill.

What's your printer? 150 travel also seems a bit low of it actually can handle 1G acceleration. Also you're limiting your max speed at 120 (last 2 boxes), so your printer won't do that 150 from infill. You could just set everything to 0 where you have 120+mm/s or 100% and do 120mm/s everywhere by just using autospeed.

-

Hey, thanks for the reply

My printer is a heavily modified Tronxy X5S - very few original bits remain on it... Even after the 3-4 years of owning it, I've never got it to a point where I'm happy with the results. I'm slowly getting there, but I struggle with ringing/ghosting, which is probably the cause of the low values for the M566 command. Currently rebuilding the bed support as I think there's some flex in there.

My printer is a heavily modified Tronxy X5S - very few original bits remain on it... Even after the 3-4 years of owning it, I've never got it to a point where I'm happy with the results. I'm slowly getting there, but I struggle with ringing/ghosting, which is probably the cause of the low values for the M566 command. Currently rebuilding the bed support as I think there's some flex in there.

-

@dzg7pl have a look at the VzBot. It too started out as a heavily modified tronxy S5ZYX123. Maybe you can get some inspiration there.