Accelerometer readings

-

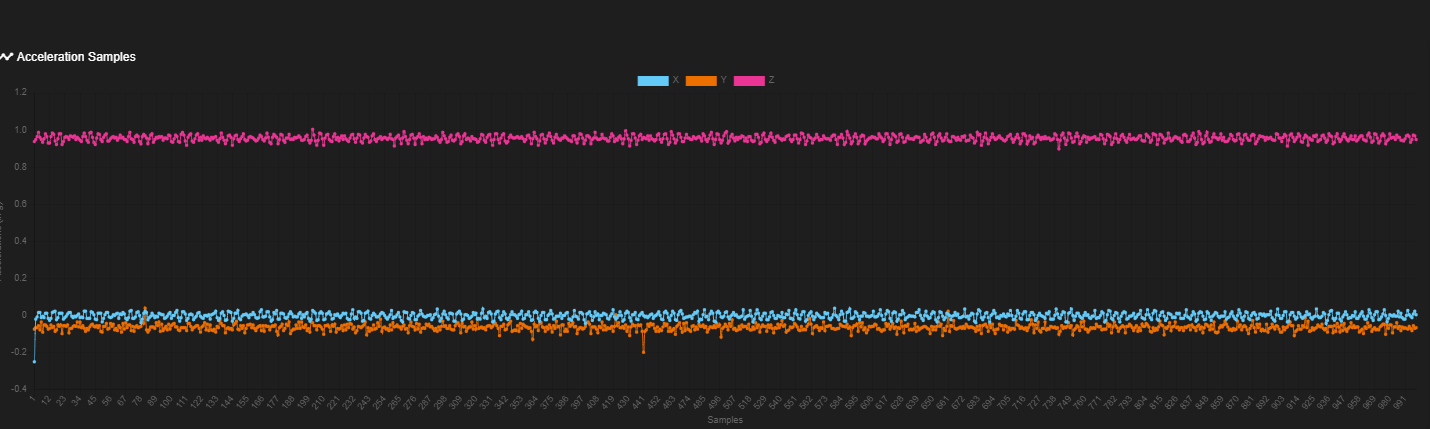

I have the LIS3DSH hooked up and am able to take readings. However if I take a measurement while the extruder is stationary, it still shows that the extruder is accelerating according to the graph. This is what the graph looks like if I take a measurement without moving the extruder

Am I interpreting this correctly?

-

@alecsanchez What acceleration are you seeing in the graph? If you mean the Z acceleration, that will probably have a value around 9.81 and is due to gravity, that's normal. The slight offset between X and Y probably means that you do not have the sensor mounted completely level and that a small part of the gravity acceleration is being picked up by the X sensor. The slight fluctuations are down to noise and are normal. If you record a set of samples with movement (or just after) you should see very different data.

-

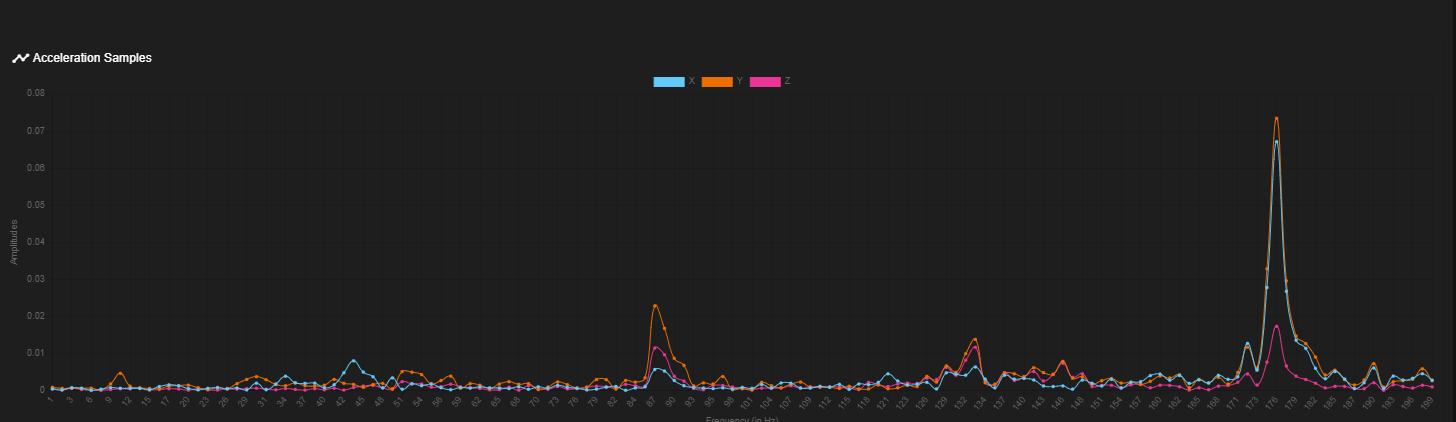

@gloomyandy Yes I understand the Z-axis reading due to gravity. But ah that makes sense regarding it not being mounted completely level, thanks for that. I took a reading during a print and it looks like this:

So in the X and Y axes i'm getting a resonance of roughly 176Hz. Is that a typically high frequency?

-

176Hz is quite high but not entirely impossible with very tightly tensioned belts (overtensioned IMO).

-

IMO 176Hz is more likely to be vibration from a small fan. Were any fans running when the readings were taken?

Typical resonant frequencies of belt-driven motion systems are in the region of 40Hz. The frequency varies with the square root of belt tension, so you would need to quadruple the tension to double the frequency. Frequency varies inversely with the square root of hot end mass, so quadrupling the mass will halve the frequency.

-

@dc42 This was taken while the part cooling fan and extruder cooling fan were on during a print. It is interesting though that I don't see any improvements from input shaping until about the 150Hz to 200Hz range. Anything higher than that, ringing appears to be re-introduced

-

@dc42 some of the newer CoreXY designs (Voron, V-Core) easily reach around 80Hz when built correctly.

-

@oliof I can believe 80Hz, because Vorons have lightweight extruders. I find 176Hz very hard to believe though.

-

@dc42 I completely agree. Some guides point towards very high tension on belts, but at those tensions you run high risk of bending motor shafts or breaking idler bearings ....