Configuring X stop for "e0stop" pin

-

I'm having trouble getting my duet wifi 2 to recognize that I have remapped the endstop for the X axis to the "e0stop" pin. Despite seeing the led next to the correct driver flash off when the endstop is pressed, when using the m119 command to check endstop status it reads triggered whether or not the endstop is pressed. I've tried messing around with it for a bit but still haven't found anything that works. Despite this minor issue the Y stop works perfectly as is.

Here is my config:

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 p4 s1

M584 X3 Y0 Z1 ; set drive mapping

M584 E4

M92 X80 Y80 Z400

M92 E453 ; Set steps per mm

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M566 X1200 Y1200 Z24 E300 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000 Y30000 Z600 E3000:3000 ; Set maximum speeds (mm/min)

M201 X500 Y500 Z100 E25:250 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800:800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout ; Set idle timeout; Axis Limits

M208 X0 Y-3 Z0 S1 ; set axis minima

M208 X275 Y300 Z360 S0 ; set axis maxima; Endstops

M574 X1 S1 P"e0stop"

M574 Y1 S1 P"ystop"

M558 P5 H5 F500 T4000 X0 Y0 Z1 ; Set Z probe type/mode 5. Not using on XY, but using it on Z.

G31 P25 X34 Y-17 Z3.1 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 x50:250 Y50:250 s30

;filament out sensor

M591 D4 P1 C"e1stop" S1; BLTouch - Heaters

M307 H7 A-1 C-1 D-1 ; Disable the 7th Heater to free up PWM channel 5 on the Duex bo; Heaters

M143 S265 ; Set maximum heater temperature to 265C

M305 P0 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M305 P2 T100000 B3950 C0 R4700

m570 T200; Fans

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M950 F2 C"fan0" Q500

M106 P1 C"Part cooling fan" S1 ; set fan 1 name and value. Thermostatic control is turned on; Tools

M563 P0 S"Hotend 0" D1 H2 F2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

m552 s1Any ideas would be great.

-

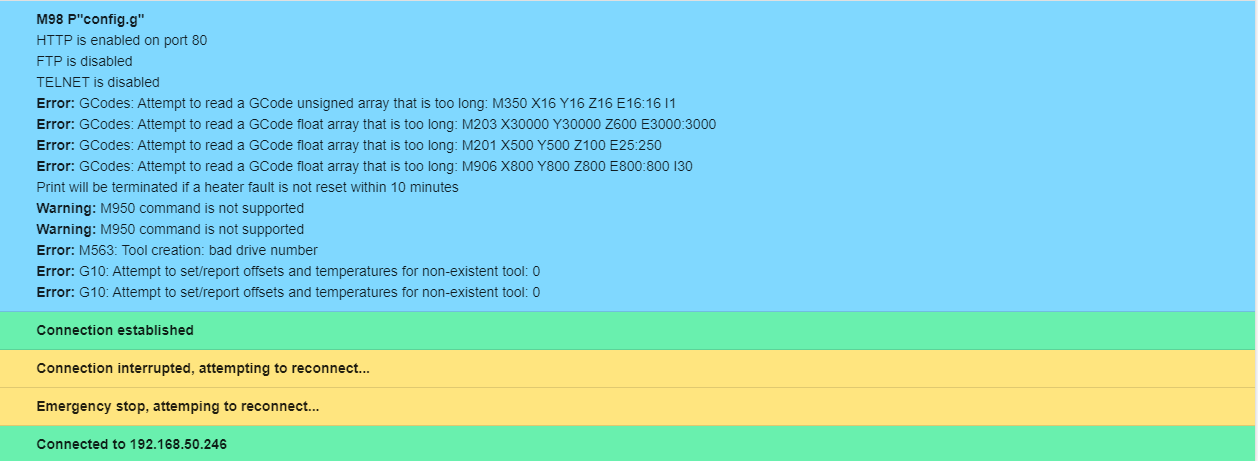

Can you send M122 and M98 P"config.g" in the gcode console and report the results here?

-

@Phaedrux

image url)

image url)Sent the reboot command then followed with M98"config.g". I haven't finished setting up the tool and don't have thermistors or heaters connected currently.

-

@Ian-Miller said in Configuring X stop for "e0stop" pin:

Sent the reboot command

No, M112 is restart. M122 is the diagnostic report.

The array too long errors are because you have two values listed for the extruder on some commands, but only 1 extruder drive mapped.

-

@Ian-Miller there is also a mix of rrf2 and rrf3 commands in your config. For example, M305 works in rrf2 but not rrf3. Assigning endstops like you have works in rrf3 but not rrf2