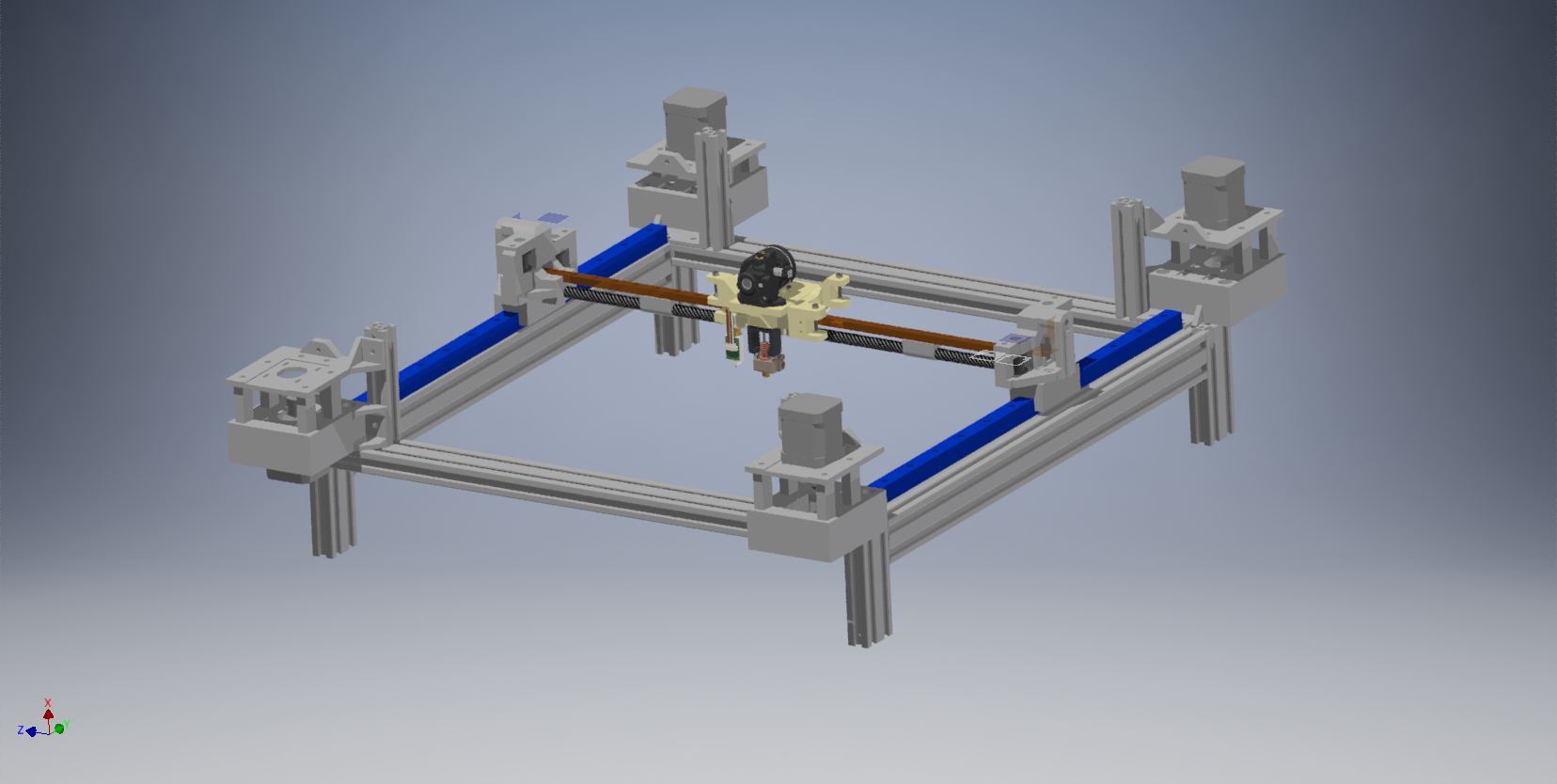

Next iteration of gantry.

-

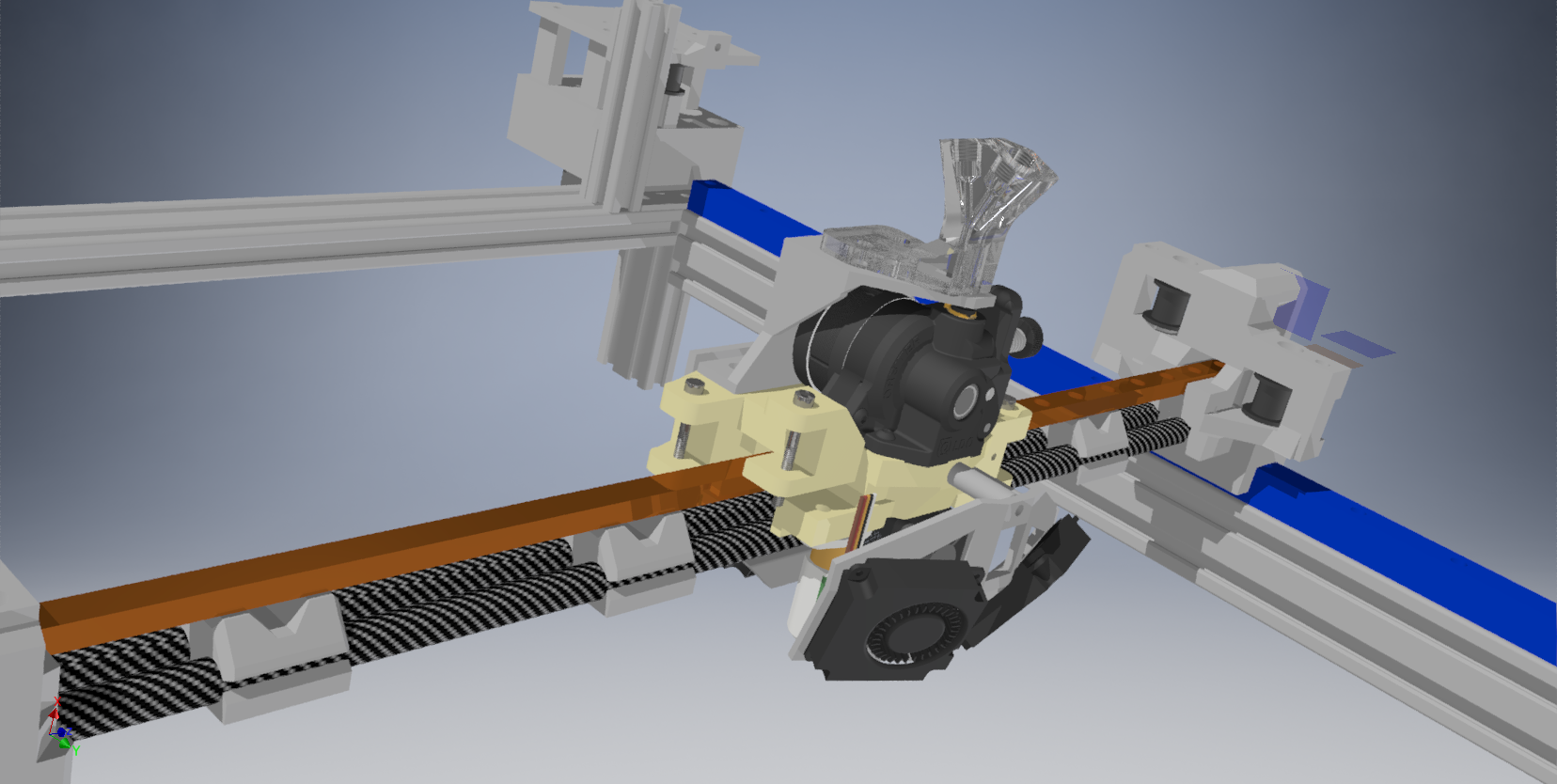

Well I recently swapped out the bmgx2 with a chimera for a mosquito, by getting rid of all that weight I finally reached closer of the speed and quality of print I've always wanted . But we are not yet there .

So I finally redesigned my motor mount to a simpler design . Next is the linear rail I was using an hiwin hgr15 rail , doing the job but heavy I intend to swap this to a mgn9 from hiwin as well , the saving weight from one rail to the under is about 500gram . Mgn9 would be supported by a carbon fiber tube .

Intent to print all the new part related to the gantry in nylon pa6 cf . For the strength and lightness. I will have a more compact hotend mount as well .

Any thing him missing or should be aware of ? Mount is still a work in progress

-

@Dad003 a light weight rail supported on a carbon fiber tube as you propose, with the extruder weight above it, might suffer from twisting as it accelerated and decelerates perpendicular to the rail. If you mount an accelerometer on the top of the motor you can see that.

-

@T3P3Tony okay I do have an accelerometer , him only at the drawing part still the carbon fiber tube is 8x10mm but I can probably find something stronger if needed .

-

@Dad003 yeah this is just an observation from another machine, however that a heaver extruder.

-

@T3P3Tony I was thinking about what you were saying , and ordered some more tubing this time 6x10 mm 2 of then so I can put these 2 under the rail with spacer in a triangular beam kinda . That should be enough to not get any issue from flex . Since my original plan was 1 8x10mm tube .

-

If you could draw your ideas in Fusion 360, or perhaps something else, you could do an FEA. Then you would know exactly how to resolve the issue. Be it material or location etc.

-

@mesacrash I use Autodesk inventor . Tried fusion 360 but I couldn't import all my file from inventor . Didn't feel like starting to redraw everything it prob a few hundred hour to do . I like to experiment anyway .

-

@Dad003 Inventor would fall under the category of, "or perhaps something else". Do FEA in Inventor.

-

Updated my design to a double carbon fiber tube .

-

@Dad003 said in Next iteration of gantry.:

Any thing him missing or should be aware of ?

My CoreXY is also supported by a carbon tube. I'm pretty happy with it. Make sure you pick a decent diameter tube and let one side float.

I did that by designing two different carriers, one side clamps the rod, the other is wider to take a 1mm thick PTFE tube, so the rod can slide to compensate thermal expansion.