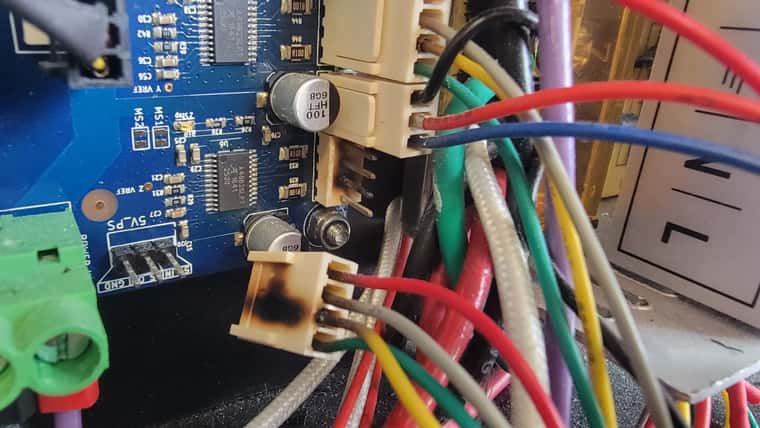

Z-axis wiring burnout

-

So, I've had this printer running at work for years. Came in this morning after a successful print and tried to start another. Z axis drive was going bonkers. Opened up the back cover and found burned connector. Any ideas as to why this may have happened?

Is this board toast?

More info: The Z-Axis has two 1.5A motors running in parallel on it: https://www.jugetek.com/product-page/nema17-60mm-1-5a-high-0-65nm-high-torque-stepper-motor

-

It can happen if one of the pins is badly crimped, or one of the wires is getting loose a little bit.

If you look up, You can see on the red wire of the 3 pin connector above, as well as the yellow wire of the 4 pin connector above that (it looks like that one might also be damaged?), that the metal part is not seated fully into the connector housing.

When that is the case, there is not a full connection to the pin on the motherboard, and that in turn can cause arcing, which over time will cause damage like you're having.

I would strongly advise you to re-crimp the wires there, those are not good crimps.

-

@Legrand, look at the bottom side of the board - it might be toast (literally).

At minimum, you need to replace both the header on the board as well as the connector on the wires. If the copper traces on the back side are damaged (that includes being heavily oxidized from heat) then you can either toss the board or you can do point-to-point wiring from a suitable undamaged area of the copper traces to the header. It might be better to have the header off the pcb (hanging off the point-to-point wiring) if the board is heavily damaged from the heat.

How this happens is if there is a connection with too much contact resistance. The current flowing through the contact resistance heats the contact and eventually you get what you see. In this case it would appear that the third connector insert from the top (yellow) was causing the issue. You could have had a bad connection between the contact and the header or, more likely, the crimp was not done correctly.