-

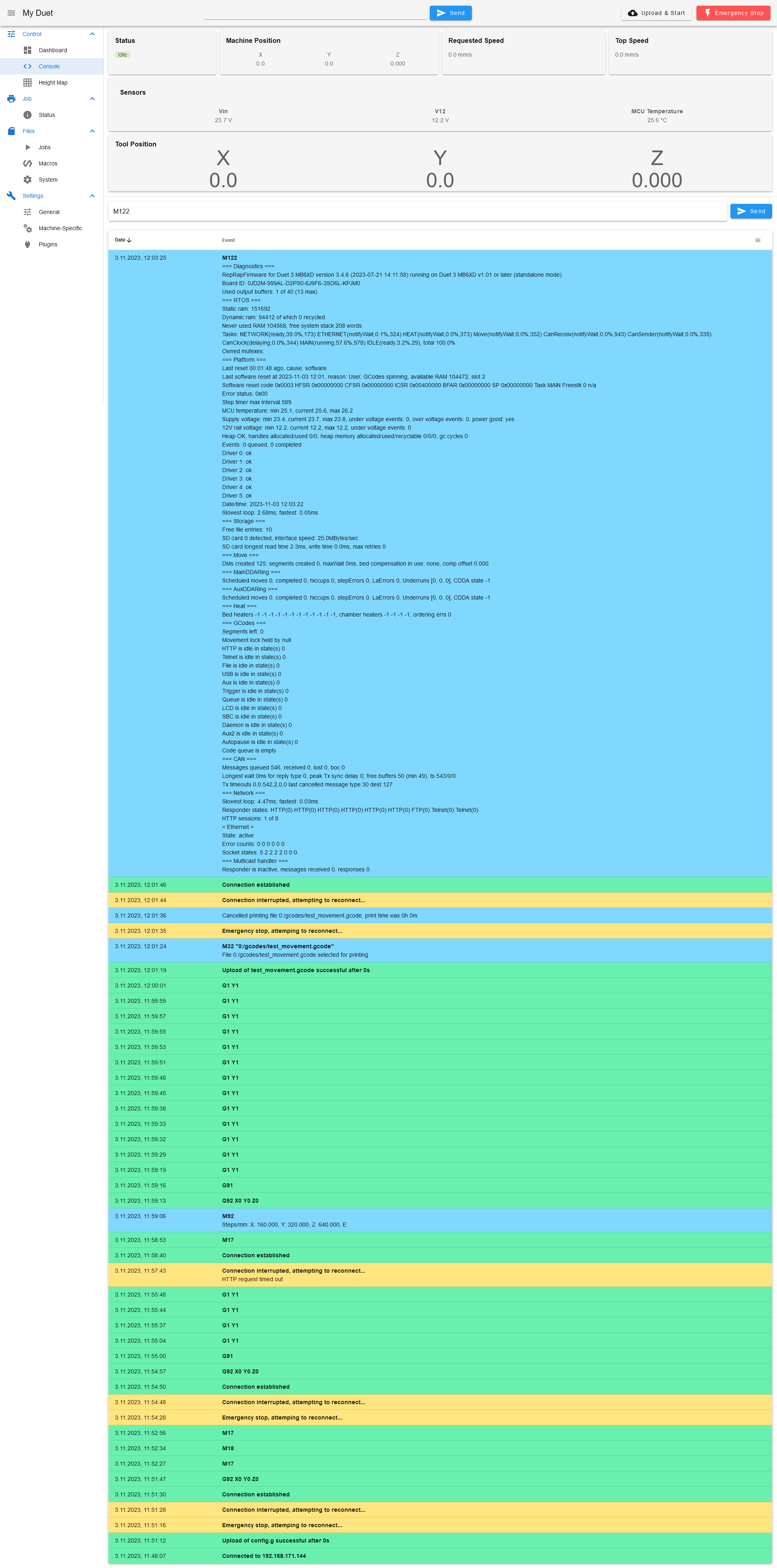

thank you for the details.

@hpiz said in Movement after M112 E-Stop!:

M564 H0 ; Allow stepper movement before homing

can you try to remove this from your config and instead set a homing for Y manual via

M92 Y0and try again?And do you use some kind of input filter on your servo drives? or are they using some sort of input filter by default?

Because the M112 command is doing different things:

- it will disable all drivers (disable the enable pin)

- will erase all movement commands from the output-queue (also from the input queue?)

- stop generating Platform Ticks

- reset gcode

-

@timschneider So these are my first experience using servo motors so I'm not really well versed with them, but I believe there is no input filtering currently set on them as per the highlighted setting in the following image link...

https://drive.google.com/file/d/1f_pghiU0pyJKdWfWDeJs9BGFsF7hdGVT/viewOk, so I've commented the M564 out so current config.g is...

; Configuration file for Duet 3 MB 6XD (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Wed Jul 26 2023 17:05:34 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M550 P"JP-60120" ; set printer name M929 P"0:/sys/eventlog.txt" S3 ; Enable debug logging ;CNC Mode M950 R0 C"out8+out5" Q20 L24000 ; Create spindle index 0, with PWM pin on heater 3 and 12000 RPM achieved at full PWM M563 P1 S"Spindle 1" R0 ; Create tool 1 with spindle 0 and call it "Spindle 1" M453 ; Select CNC device mode M669 K0 S2 T1 ; CNC Pendant Enable M575 P1 S1 B57600 ;Enable serial comm on io0 56700 baud rate ; Set up outputs M950 P0 C"out4" ; Define tool loosen pin as P0 mapped to output 8 M950 P1 C"out3" ; Define chip blast pin as P1 mapped to output 7 M950 P2 C"out7" ; Define mist coolant pin as P2 mapped to output 6 M950 P3 C"out6" ; Define touch blast pin as P3 mapped to output 4 ; Set up inputs M950 J0 C"io1.in" ;Define tool probe depressed over limit from io3 to Pin 0 M950 J1 C"!io8.in.iso" ;Define VFD Fault input from io8 to Pin 1 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.4 S0 T3:3:6:0 ; physical drive 0.4 goes backwards M569 P0.5 S0 T3:3:6:0 ; driver 5 requires an active high enable, 2.5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup time and no hold time M569 P0.3 S0 T3:3:6:0 ; driver 5 requires an active high enable, 2.5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup time and no hold time M569 P0.0 S0 R0 T5:5:9:0 ; physical drive 0.0 goes backwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M584 X0.3 Y0.4:0.5 Z0.0 ; set drive mapping M92 X160.00 Y320.00 Z640.00 ; set steps per mm M566 X1800.00 Y180.00 Z120.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y12000.00 Z5000.00 I5 ; set maximum speeds (mm/min) M201 X400.00 Y200.00 Z200.00 ; set accelerations (mm/s^2) ;M564 H0 ; Allow stepper movement before homing ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X600 Y1200 Z170 S0 ; set axis maxima ; Endstops ;M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y2 S1 P"!io2.in+!io4.in" ; configure switch-type (e.g. microswitch) endstop active low for high end on Y via pin io5.in and io2.in M574 Z2 S1 P"!io8.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in ; Z-Probe M558 P5 C"io3.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds ;Triggers M581 T2 P0 S1 ; Run trigger2.g on pin 0 active->inactive for tool probe overpress M581 T3 P1 S1 ; Run trigger3.g (EmStop) when pin 9 goes from active to inactive indicating VFD fault ; Heaters M140 H-1 ; disable heated bed (overrides default heater mapping) ; Fans ; Tools M563 P0 D0 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ;Machine Initialization M18 ; disable all steppers M17 ; enable z stepper so it doesn't fall ; Custom settings are not defined I also made a test job file...

1001.g;1001 ;T24 D=10 CR=0 - ZMIN=-1 - FLAT END MILL G90 G21 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 Same behavior...

And here is the debug log

power up + 00:00:00 [info] Event logging started at level debug power up + 00:00:00 [info] Running: Duet 3 MB6XD v1.01 or later: 3.4.6 (2023-07-21 14:11:58) power up + 00:00:00 [debug] HTTP is enabled on port 80 power up + 00:00:00 [debug] FTP is disabled power up + 00:00:00 [debug] TELNET is disabled power up + 00:00:00 [warn] Error: Pin 'io8.in' is not free power up + 00:00:00 [warn] Error: bad drive number power up + 00:00:00 [warn] Error: in file macro line 74: G10: Invalid tool number power up + 00:00:03 [debug] Done! power up + 00:00:03 [debug] RepRapFirmware for Duet 3 MB6XD is up and running. power up + 00:00:10 [warn] Ethernet running, IP address = 10.0.0.210 power up + 00:00:10 [warn] HTTP client 10.0.0.10 login succeeded 2023-10-30 17:34:44 [warn] Date and time set at power up + 00:00:10 2023-10-30 17:34:44 [warn] HTTP client 10.0.0.221 login succeeded 2023-10-30 17:34:44 [warn] HTTP client 10.0.0.221 login succeeded 2023-10-30 17:34:44 [warn] HTTP client 10.0.0.214 login succeeded 2023-10-30 17:34:44 [warn] HTTP client 10.0.0.214 login succeeded 2023-10-30 17:34:44 [warn] HTTP client 10.0.0.10 login succeeded 2023-10-30 17:36:23 [warn] Error: G0/G1: insufficient axes homed 2023-10-30 17:36:34 [warn] Started printing file 0:/gcodes/1001.gcode 2023-10-30 17:36:34 [debug] File 0:/gcodes/1001.gcode selected for printing 2023-10-30 17:36:48 [debug] Done printing file 2023-10-30 17:36:48 [debug] Done printing file 2023-10-30 17:36:48 [warn] Cancelled printing file 0:/gcodes/1001.gcode, print time was 0h 0m 2023-10-30 17:36:48 [info] Event logging stopped Then, based on your comment about the servo input filtering, I decided to test both my Y axis servo motors, and my Z which is a stepper...

1001.g with Z movement

;1001 ;T24 D=10 CR=0 - ZMIN=-1 - FLAT END MILL G90 G21 G1 Y500 Z100 F4000 G1 Y600 Z0 F4000 G1 Y500 Z100 F4000 G1 Y600 Z0 F4000 G1 Y500 Z100 F4000 G1 Y600 Z0 F4000 G1 Y500 Z100 F4000 G1 Y600 Z0 F4000 G1 Y500 Z100 F4000 G1 Y600 Z0 F4000 And in the video below, the stepper also moves after the first stop (though not as far or as long as the servos, not sure if the amount of movement per axis has any impact), so even with steppers, there would still be enough movement to easily break a tool or shove the tool right through my part or bed. (Note: the Z axis stepper is the thing with the yellow tape flag spinning with the shaft)

https://drive.google.com/file/d/1ffUtCYofIbbLlfk8L9m_zjEHs5LbMnmi/view?usp=sharing

I've also noticed I can get pretty much 100% failure rate by triggering an estop near the end of a move.

-

@hpiz Idk if it matters, but I didn't explicitly mention that all my axes are driven with closed loop external drivers.

-

@timschneider I also want to really share my appreciation with you trying to help me out with this, you could just ignore my problems and focus on your own stuff, but to be getting support from a fellow CNC'er (who has an epic router) does not go without my gratitude. I commend your interest in getting more CNC machines running on a Duet!

-

@hpiz

are your drivers enable active high or active low?@hpiz said in Movement after M112 E-Stop!:

Utilizing enable signal on all drives, currently active disabled/low (plan to reverse in future for safety)

can you tell in which position the driver enable jumper is?

Driver Enable Polarity A jumper in the "left" position is used for external drivers which are enabled when a voltage is applied to the enable connection (Active Enable). A jumper in the "right" position is used for external drivers which are disabled when a voltage is applied to the enable connection (Active Disable) (Note the v0.1 boards have the silkscreen reversed). M569 P0.4 S0 T3:3:6:0 M569 P0.5 S0 T3:3:6:0 This will fallback to the default, because no R parameter is set, and the default is active low:

Rnnn Driver enable polarity: 0 = active low, 1 = active high, -1 = driver is always disabled and is not monitored (default 0) -

@hpiz I am trying to understand this behaviour. When M112 is processed it disables all drivers immediately and shuts down the movement system. So I don't see how movement can continue.

Do you see the Driver Error message in DWC? Unfortuately your video is not clear enough for me to read the message boxes on the laptop.

-

@timschneider Currently Active low on all drivers. Jumper is on Active Low, (left for me because I mounted the board upside-down)

Also, M18 and M17 work exactly as expected for all or specific drivers.

@dc42 I currently have a driver-error system macro, it was suggested to try removing my M291 message pop-up that I had indicating which driver failed (pretty much identical to the default message when driver-error doesn't exist), so it doesn't have any popups right now, my driver-error system macro is just a single line, M112. Having said that, when the message was in the macro it showed the correct driver that throws the error. The only visual indication of driver error is the yellow toast on the bottom of the laptop's screen indicating "Emergency Stop: yada yada"

Let me know whatever information/videos you need related to this.

BTW I've been uploading all the my images and videos to Google Drive which compresses the preview for both file types. If you download the files the quality of both is much better.

There's really not much physically set up on this machine so I am more than willing to try watered down/minimalist/test config.g's since I only have the one axis actually fully wired and assembled mechanically(the dual Y).

I also have an analog oscilloscope that may become useful, although a digital one would be more appropriate.

-

@hpiz said in Movement after M112 E-Stop!:

Also, M18 and M17 work exactly as expected for all or specific drivers.

that was the next check I had in mind

so I'm starting to run out of ideas.

But one thing I've noticed while looking at the wiring/jumper picture is, that the GND Pin of the driver header is not connected. Can you show us a picture of the duet, one servo driver and the z-closed loop driver wiring? And maybe provide the datasheet for the drivers.

Cause I needed the seperate GND connection between the Duet and each closed loop driver, for the alarm pin.

And another thought, is your power supply strong enough to provide the over current in the stall event?

I have not been able to observe this behaviour with my setup, so this is the reason why I try to understand this as good as possible and in the end hopefully solve the problem for you as well

-

@timschneider Seeing as the control signals for drivers pull to ground and all my drivers use optoisolated inputs, I am using 5v as common and the only ground connected per cable is the shield ground which flies over with the endpoint signal wire over the the IO headers and is grounded there.

My alarms for the servos are optoisolated for pull up, the z driver for the stepper is reverse poloarized optoisolated for pulldown, so I actually have the error pin for that one going to common (shared with alarm and brake) and 5v going into it's alarm output. I will eventually change to the proper setup and place a resistor between 5v and the alarm output, and ground on common to create an error low circuit. And then through configuration of integrated servos, change the output to be on when not in error so all drivers are error low.

I'm using JMC 400W integrated servos on Y and X

JMC ManualAnd the Z is a StepperOnline closed loop 400W stepper

StepperOnline driver ManualRegarding power supplies, I actually don't know if there is enough overhead for stall current when it is moving at full speed and the 50kg of gantry and spindle are attached, but I think at the slow speed it is moving during these tests, and only moving the rotational inertia of the ballscrew plus the linear inertia of the little linear bearing, I would guesstimate there is little to no backfeed during these test.

There is one power supply for the Duet and 24V accessories (endstops, relays, solenoids,etc...) and one for each driver. The Duet/Acc PSU is 480W and the driver ones are all 36V 600W, all PSU's are switch mode.

Edit: forgot the other pics

All driver wiring uses the following color code:

Yellow - 5V

Blue - Step/Pulse

White - Dir

Green - Enable

Red - Error/Alarm

Orange - Endstop input (except Z, unused for Z)

Brown - Unused

Black - Unused

Shield - Ground on Duet sideJust a pic showing the orange endstop signal wire going to the endstop wire

-

@hpiz hm, so I don't see anything wrong ...

Out of curiosity, can you try running your movement job file and pressing the emergency stop in the DWC? is it still moving? -

@timschneider When I get home from work today I'll grab that video evidence, but it does the same thing, albeit sometimes heavily delayed (~3-4 seconds), due to my WiFi I think, I've been having some intermittent disconnect issues with it lately.

@dc42 would know best I think, but is it possible there is a need to either reflash my firmware, or possibly an issue with the board (I find the latter hard to believe).

-

@hpiz maybe a dumb question, but do you have a while loop in your daemon.g without a G4?

I try to understand what is causing the delay, as dc42 said, if the M112 is processed, there should be no delay. So something is maybe delaying the processing of the M112, but again that is not explaining the first and the second stop. That was the reason why I asked for the power supply (short power down/undervoltage can cause many different sotware problems), but I think this is sufficient. The reason why I keep asking about the while loops without a "break" is, that the control of the gcode processing is not handed back to process other codes if it is running in a tight loop. Or if for what ever reason there is a blocking(queueable) G-Code infront of the M112, the processing of the M112 will be delayed e.g. turn a relay off with M42 (that was the reason why I asked you to put the M112 at the first and only position of the driver-error.g).

On last idea is, to wire an e-stop and configure it as a estop in duet - just to rule the gcode processing out. if this also failes, it is something in the movement system or the drivers itself, but I don't think it is related to the drivers cause you are using two different kinds of drivers (servos and steppers)

e.g. recycle your tool probe depressed over limit and uncomment T2 under triggers

M581 T0 P0 S1 R0 -

@timschneider Here's a test without the additional modifications you suggested using the EStop button in DWC...

https://drive.google.com/file/d/1hTqF0GCi4dEQjOZyk1uR_Ctzywv-66Zg/view?usp=drive_link

I really think the delay I mentioned is just a network communication delay and not a delay within the Duet itself (it's not delayed every time), but I could be wrong. I would rate this test as having zero delay, as soon as I hit the button the first (very short) stop happened "instantly".

@timschneider said in Movement after M112 E-Stop!:

maybe a dumb question, but do you have a while loop in your daemon.g without a G4?

I don't think any question about this behavior could be considered dumb, but no, I haven't even made a daemon.g, the only configuration I've done so far is the config.g, a few custom M command system macros, and the driver-error system macro everything else is stock.

Screenshot of Duet System Files

^Any file with a modify date of 7/26/2023 is unmodified. Everything other than config.g is very very simple, but let me know if I need to share the contents of any of them.@timschneider said in Movement after M112 E-Stop!:

I keep asking about the while loops without a "break" is, that the control of the gcode processing is not handed back to process other codes if it is running in a tight loop.

I agree completely, it's what I would assume first as well, that would presumably have the same effect I'm having, but I only ever had the one loop in my movement test macro, no other loops were defined by me anywhere else.

And finally, I changed the tool probe overpress trigger to T0 and got the same behavior...

https://drive.google.com/file/d/1hVCYuPwHx6Yzlz80FHZKv9pIseA7QbPQ/view?usp=sharing

-

@hpiz thank you for all these test and based on these tests I think, we don't need to focus on the driver-error or external driver configuration. It appears to me, that there is a problem with the following configuration

- Duet 3 Main Board 6XD standalone mode

- Emergency Stop (DWC and external trigger confirmed)

- Active disabled/low external drivers

So may I ask you to do two more tests?

- check if the stepper motors are active or disabled after the final stop, are you able to move them freely or not? If they are blocked/active that could describe the first and second stop.

- put a M112 in the job file, somewhere in the middle. If the Y-axis is moving after the M112 in the job file, than there is a bug in the software, as the M112 is in the same input channel as the movement commands and there is no "normal" way, that movement will appear after the m112.

-

@timschneider So I'm starting to lose my mind, and have begun talking to myself on video (lol, really so I have to type less, but I am starting to get quite lost)

Disclaimer: While my Z stepper can and has moved after a first stop of M112, it is far far less consistent, more than 80% of the time it stops only once as it should (compared to like 2% for the servos). But while the hardware differences clearly are making a behavioral difference, I believe the underlying cause (that I am currently convinced of) is still a problem. I'll get there...

@timschneider said in Movement after M112 E-Stop!:

Active disabled/low external drivers

I'm starting to narrow onto this or something about the enable signal (although the pulse/step signal is still misbehaving imo), and it could be as simple a fix as a wiring change.... maybe, I'm still very confused though. And my gut tells me no wiring change can fix this.

I'm getting confused about the effect of the Enable jumper, I can have it on either position and the drivers are active with no other changes to Duet config or driver parameters.

Also within config.g what does enable high (R1) on a driver mean if the enable pin is actually a ground sink, does that mean enable high (R1) means the transistor is on for the Enable(-) pin meaning it's actually pulled to ground, because that appears to be what I'm seeing. Enable low (R0) keeps my enable wire high since I have it fed by 5V through the optoisolater at the servo. And when I switch to enable high (R1) the enable wire is low, indicating current is passing through the opto on the driver.

@timschneider said in Movement after M112 E-Stop!:

check if the stepper motors are active or disabled after the final stop, are you able to move them freely or not? If they are blocked/active that could describe the first and second stop.

M18 test + EStop drive enable check - Conclusion: Stepper and servo motors are disabled after final stop

@timschneider said in Movement after M112 E-Stop!:

put a M112 in the job file, somewhere in the middle.

M112 mid job - Conclusion: Same effect

Oh, I didn't stop there (warning: the oscilloscope will make an appearance)

M112 in job with M291 right after - Conclusion: M291 is not executed but G movements are

M112 at end of job expecting no strange movement - Conclusion: Still moved after a stop...

Investigating that last test a little deeper - Conclusion: Yup, it did still move, and past where it should have. Ok, obviously the buffering of move commands is superseded by the M112 which executes as soon as it's read.

What about the Z stepper, it does behave somewhat better - Conclusion: I'd say you can see a few steps after the first pause, but much better than my other drives.

Ok let's test the x axis - Conclusion: You can see a clear stop and restart, then final stop just like the Y. While I say in-vid it's about the servo's, I'm not sure they are to blame, there's more.

I kept going off video to try reversing the enable polarity in both the servo params and the duet, I found some quirks I mention in the next vid but it's really not in my focus right now. Anyways, none of that changed anything about the behavior.

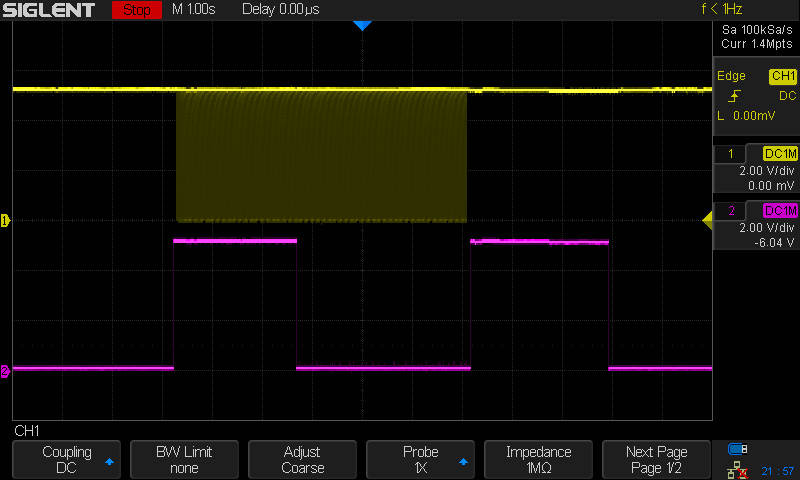

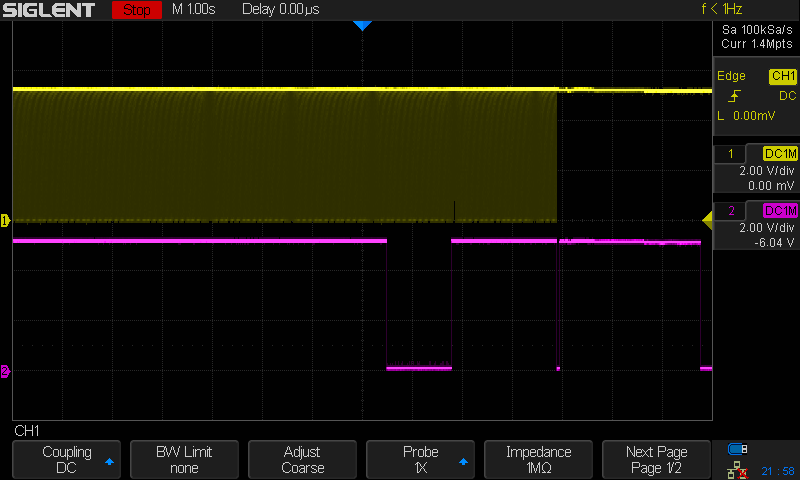

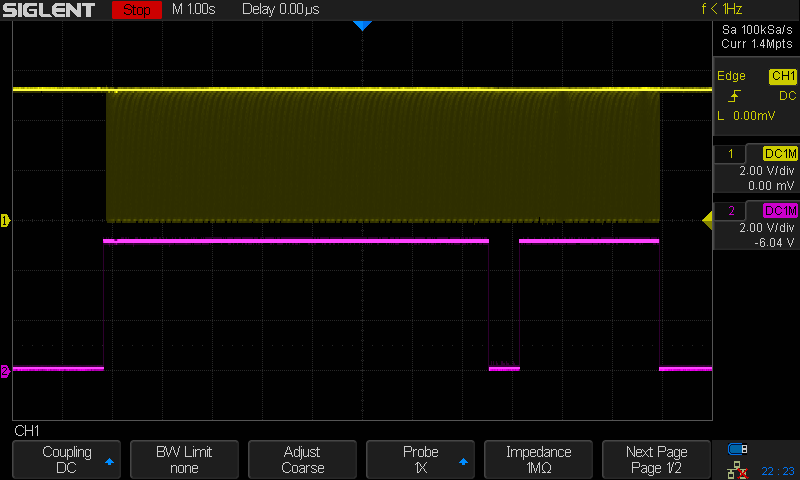

At this point I felt I had no option but to pull out the scope. I'm analyzing the following video with the following assumptions...

-

There is no signal being generated by the driver, the signals seen on scope are entirely from the Duet, I feel that's a pretty safe bet.

-

The difference in behavior between my Servo's and my Z stepper is down to some kind of buffer/safe time between disabling the drive and re-enabling. I would have to either also assume most drivers have said wait time, or my board is acting differently.

Watching the control signals on scope in realtime

After this test, I really can't blame the servo's at all. They're doing exactly what they are being told to do by the Duet, think it might be time give up. Why would there be steps still coming out of the duet after a stop? Why would the enable signal go to disable->enable->disable? I really am having a hard time trying to think of any configuration or parameter I can change to just have the Duet not send steps after an M112 let alone deactivate, then reactivate a driver.

-

-

@hpiz I don't have the energy today, but I plan to show the same signals going to my z driver, but being ignored by the driver, which I assume will be the case. I mean why would one drive output behave differently from another?

-

@hpiz Thanks again for all these tests and measurements that go far beyond what I would have asked for.

I guess I can't help you any further and @dc42 needs to take over, as it appears to me, that there is a problem with the following configuration:

- Duet 3 Main Board 6XD standalone mode

- CNC Mode

- Firmware 3.4.6

- Emergency Stop (DWC, gcode (M112 even within the jobfile itself) and external trigger (trigger0) confirmed)

- Maybe: two motors on one axis

Observed behaviour:

- movement commands are queued and the Movement System starts to move the drives

- M112 is processed

- all drives are disabled

- at least one movemend command is still being processed in the queue and this will reactivate the drives again

- all drives are disabled again (is it done by the M112 or maybe a stop.g/cancle.g?)

maybe I can reproduce it with a simple bench setup.

-

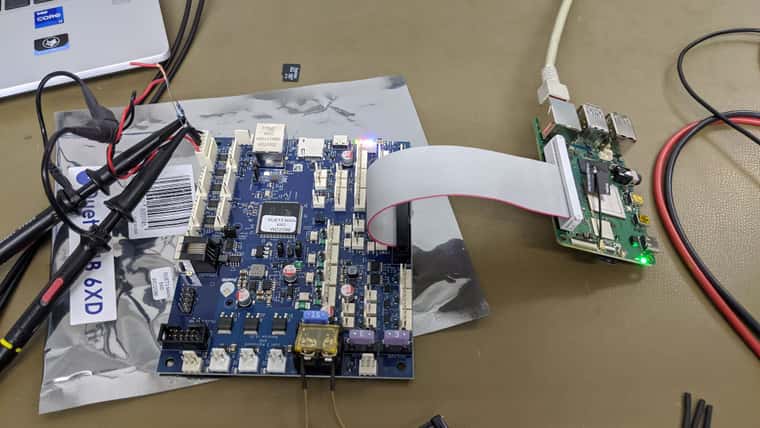

@dc42 I was able to reproduce this behaviour with an brand new of the shelf 6XD WD32096 v1.01 firmware 3.4.6 reflashed to be sure. In standalone mode.

Enable Jumper in active Enable.

Following config.g

; Enable network M552 P0.0.0.0 S1 ;CNC Mode M453 ; Select CNC device mode M669 K0 S2 T1 M569 R0 P0.4 S0 T3:3:6:0 ; physical drive 0.4 goes backwards M569 R0 P0.5 S0 T3:3:6:0 ; driver 5 requires an active high enable, 2.5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup time and no hold time M569 R0 P0.3 S0 T3:3:6:0 ; driver 5 requires an active high enable, 2.5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup time and no hold time M569 P0.0 S0 R0 T5:5:9:0 ; physical drive 0.0 goes backwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M584 X0.3 Y0.4:0.5 Z0.0 ; set drive mapping M92 X160.00 Y320.00 Z640.00 ; set steps per mm M566 X1800.00 Y180.00 Z120.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y12000.00 Z5000.00 I5 ; set maximum speeds (mm/min) M201 X400.00 Y200.00 Z200.00 ; set accelerations (mm/s^2) ;M564 H0 ; Allow stepper movement before homing ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X600 Y1200 Z170 S0 ; set axis maxima ;Machine Initialization M18 ; disable all steppers M17 ; enable z stepper so it doesn't fall test_movement.gcode

G90 G21 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 G1 Y500 F4000 G1 Y600 F4000 EmergencyStop pressed mid job via DWC

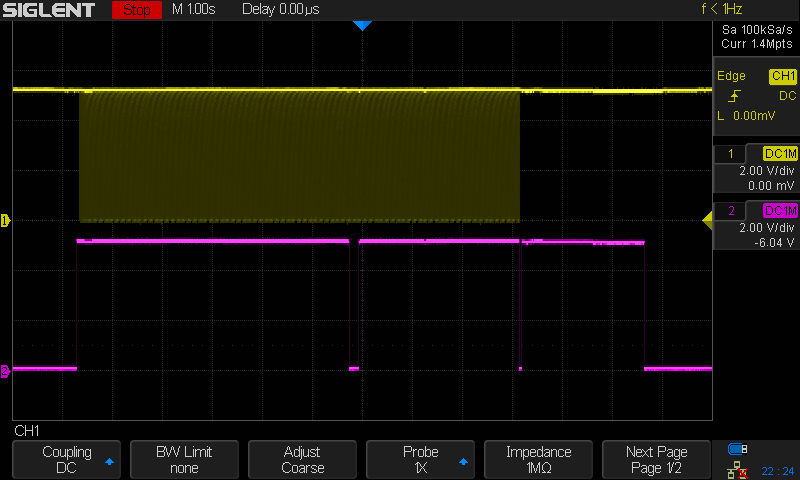

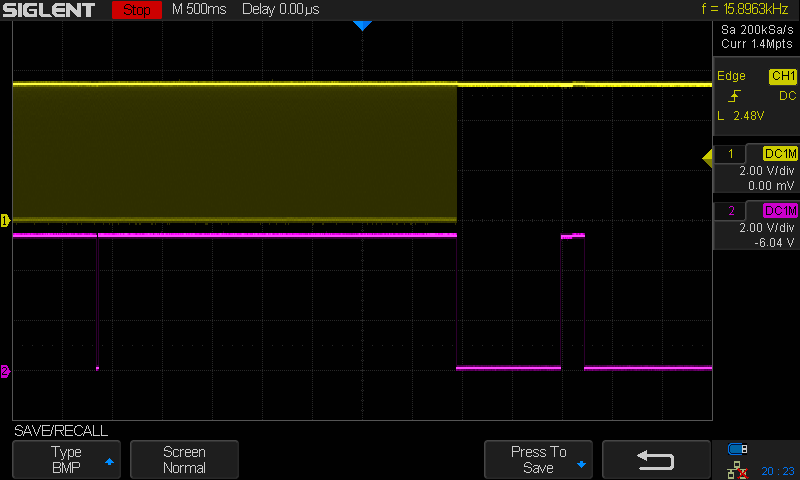

Channel 1 (yellow) is STEP-

Channel 2 (pink) is ENABLE-

there is a ENABLE low, when the Emergency Stop is pressed, then high again, then low, high, low again (low is off in this setup). I've tried it also the other was around with R1 - it just inverts the curve.

-

@timschneider If you still have the test system available, is there any chance you could run the test again but use M112 entered in the console rather than using the emergency stop button. The reason I ask is because the emergency stop button in DWC runs M112 followed by M999 so some of what you are seeing may be down to the software reset (M999) operation.

-

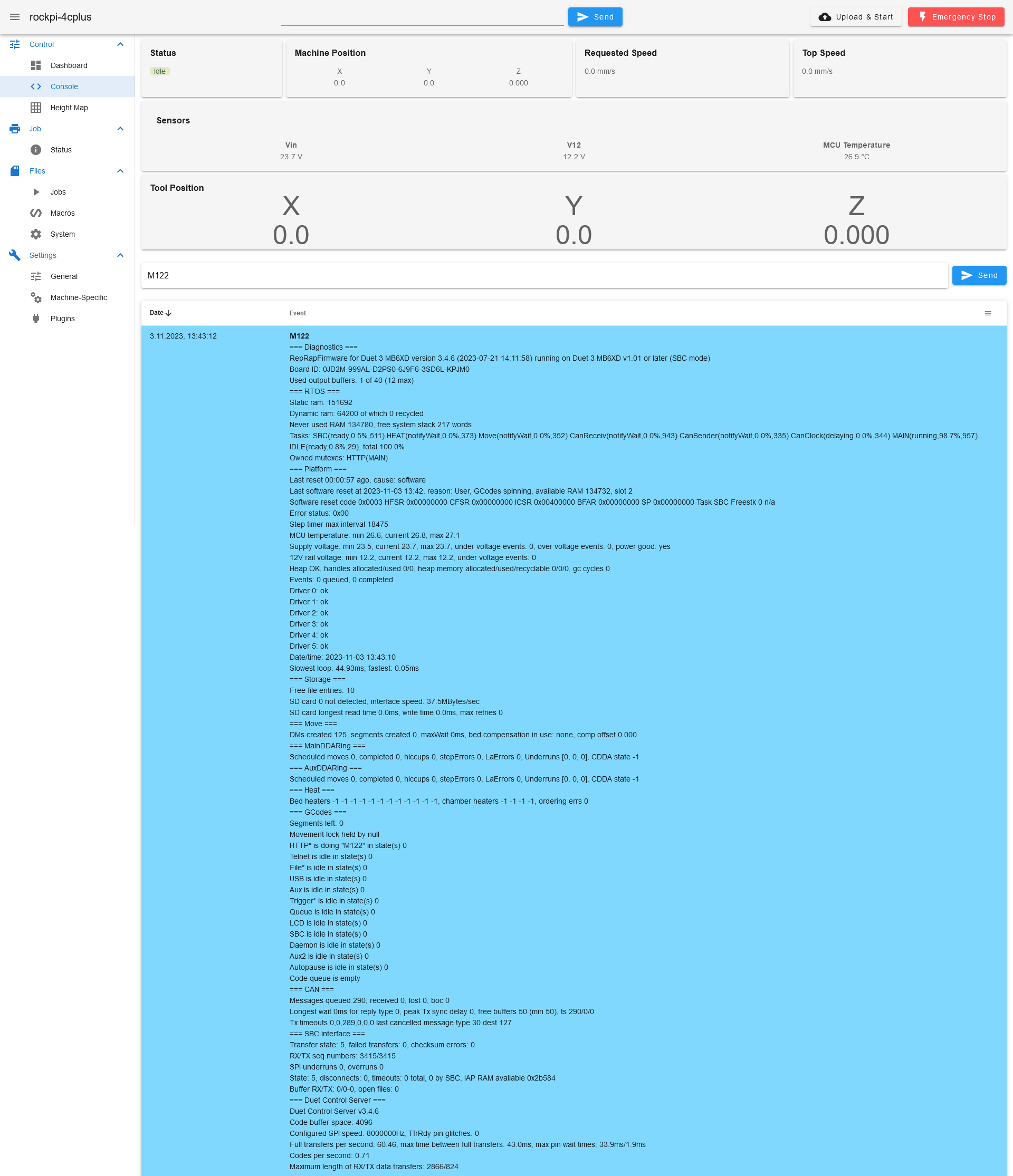

@gloomyandy sure. I did even more tests.

run M112 from console will change the behaviour a bit, the last disable / enable toggle will disappear. It appears to me, that a reset will also toggle the driver enable once.I've changed the test setup to be able to test the sbc setup.

Unfortunately, it will also fail, so there is also movement after the M112.the following screens are all taken with SBC setup 3.4.6

and the following config.gM669 K0 X1:0:0 Y0:1:0 Z0:0:1 S1 T1 ; Cartesian kinematics ; Drives M569 P0 R0 T1:1:2:0 M569 P1 R0 T1:1:2:0 M569 P2 R0 T1:1:2:0 M569 P3 R0 T1:1:2:0 M569 P4 R0 T1:1:2:0 M569 P5 R0 T1:1:2:0 M569 P0 S1 M569 P1 S1 M569 P2 S1 M569 P3 S1 M569 P4 S1 M569 P5 S1 G90 ; send absolute coordinates... M584 X0 Y4:5 Z3 ; set drive mapping M92 X400 Y400 Z800 ; set steps per mm 4000 steps/rev / 10 mm pitch - 5mm on z M566 X120.0 Y120.0 Z120.00 P1 ; set maximum instantaneous speed changes (mm/min) and apply jerk on every move M203 X10000.00 Y10000.00 Z7000.00 ; set maximum speeds (mm/min) M201 X400.00 Y500.00 Z1000.00 ; set accelerations (mm/s^2) M204 P250 T1250 ; Set printing and travel accelerations M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1330 Y1036 Z278 S0 ; set axis maxima ; Mode Selector M453 ; Select CNC Mode