BL touch bed lowering till bl touch errors out from not touching

-

I hope I copied the files right this time? First time doing this.

Still having issues with bltouch homing and running bed calibration. Made the changes but when homing same thing? Z axis goes to bottom when homing and then up about 1/2 way before it stops and says bl touch probe did not touch. ALSO The x and y axis homes to the right place then will go to the far opposite side of the bed when the bed comes back up? Ran the rrf configurator again and put bltouch as z endstop.

Without the changes you recommended the machine homes properly but the bltouch bed program does not work. With the changes it does as above.

Any advice. Let me know if you need any more codes. Thank you; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 3 Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X220 Y220 Z300 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X20 Y0 Z3.3 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.532 K0.167:0.000 D13.56 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F12000 ; lift Z relative to current position G1 H1 X225 Y225 F6000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-5 Y-5 F12000 ; go back a few mm G1 H1 X225 Y225 F240 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G31 X-5 Y15 F12000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X-5 Y15 F6000 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G3 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning ;; retractprobe.g ; called to retract a physical Z probe ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) M280 P0 S90 ; retract BLTouch -

@ecnsupplies said in BL touch bed lowering till bl touch errors out from not touching:

In homeall.g there is an error. You have:

G90 ; absolute positioning G31 X-5 Y15 F12000 ; go to first bed probe point and home Z G30 ; home Z by probing the bedThe

G31should beG1. Also, I'd tend to home in the centre of the bed; that's where most printing is done. So perhaps change it to:G1 X110 Y110 F12000 ; go to first bed probe point and home ZIan

-

That put the hotend in the middle of the bed but the z axis still goes down instead of up when you click home.

If i touch the bltouch probe by my finger when its going down it stops. Is there a way to tell the z to go up instead of down when homing. It did when i use the stock configuration. So it cant be the motor axis direction?? -

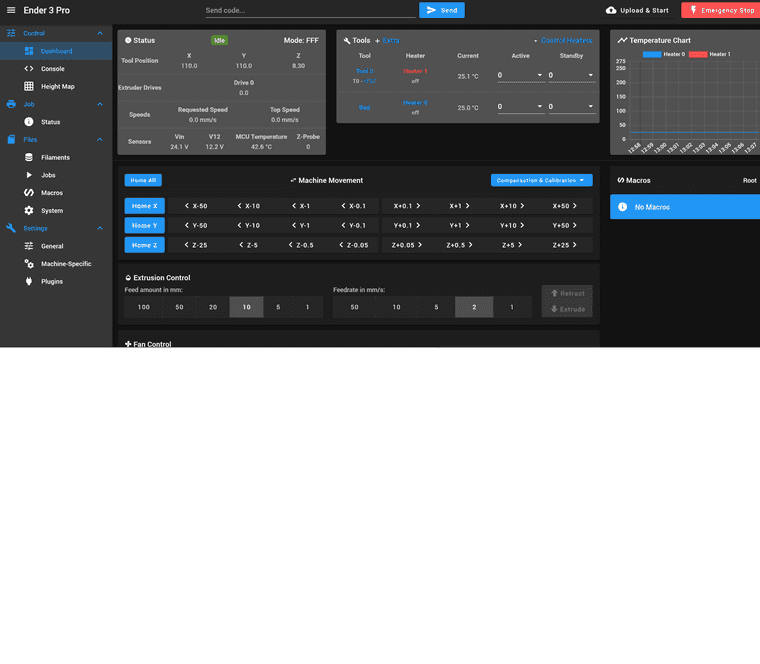

@ecnsupplies I still don’t know what board or firmware version you have. Please send M115 in the console and post the response. Then I can check your probe setup.

In DWC, what number do you see for Z probe when it is NOT triggered?

Ian

-

@droftarts said in BL touch bed lowering till bl touch errors out from not touching:

DWC

m115FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.6 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2023-07-21 14:11:38

Every thing is latest visions and i stayed away from beta

In the dwc it says 0 on the bltouch

Just in case here is the bed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) M561 ; clear any bed transform G29 ; probe the bed and enable compensation -

@ecnsupplies said in BL touch bed lowering till bl touch errors out from not touching:

z axis still goes down instead of up when you click home.

If you send G92 Z100 in the gcode console, it will pretend the z axis is homed and at the 100mm position. You can then use the jog buttons for the Z axis to test if it's actually moving in the correct direction.

+Z should move the bed and nozzle apart.

-Z should move them together. -

I have know why the rrf conf has the z axis going forward and the rest backward or when i use it without any modifications it work on homeing BUT That fixed it!

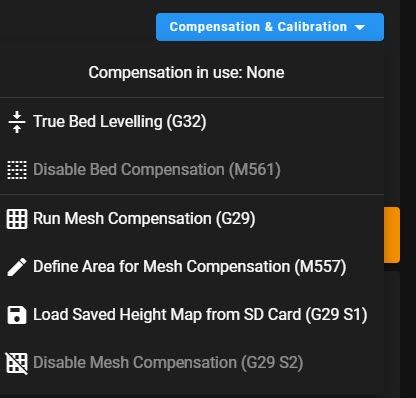

Still have a issue when i run the command g32 or g29 the bltouch probe goes off the far corner edge to start and says cant touch the bed. what can i do to have it start in the middle or at a edge to calibrate the bed?

Thank you for all your help -

The direction of rotation depends on a few things that aren't always known like the order of the wire pairings from the motor, orientation of the leadscrew, etc. You need to test it and determine if it's correct during commissioning.

G29 for mesh compensation uses the M557 command to define the extents of the grid to probe. If it's going off the edge, you need to adjust that command.

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_mesh_bed

-

@Phaedrux said in BL touch bed lowering till bl touch errors out from not touching:

M557

I found the issue!. On ender 5 the bed size under axis limits is X220 Y220 Z300

Because the probe sticks out over 2 inches on X from the nozzle i adjusted the x to 208 instead of 220. It is now working.

Now just need to work on leveling the bed. Hope this is all i will need.

I appreciate all your help. -

Just FYI in regards to G29 and G32.

If you read the docs closely you will find that G29 will execute a file named mesh.g if it finds it.

G32 will execute the file bed.g.

G29 is related to Mesh Bed Compensation which is a feature for coping with bed unevenness.

G32 is related to Auto/Manual Bed Leveling which is a feature for getting the bed parallel to the plane of the XY gantry OR to look at it another way to get the bed perpendicular to the Z axis.

It is not uncommon to see folks use G32 to run bed.g and in bed.g there is code to create the heightmap needed for using Mesh Bed Compensation.

In the Duet Web Interface they are menu options which assume you are using G32 to perform Bed Leveling and G29 to create the height map.

It's your printer and you can do whatever you like but if you wish to be consistent with the documentation and the web interface you may wish to code bed.g and mesh.g accordingly.

Frederick

-

Yes familiar with that. Thats why i got the bl touch because using a paper and moving it a hundred times. LOL

Thank you for the advice