G32 doesnt save after True Bed Leveling

-

@johny That start should be fine. The G30 is setting Z0 at the bed centre anyway. And you are loading a bed mesh. What does your bed mesh look like? Maybe share a picture of the printer.

@fcwilt said in G32 doesnt save after True Bed Leveling:

I don't know if G32 behaves differently with two Z steppers but on my three stepper printer, which has 0,0 in the middle of the bed, it appears that the 1st Z stepper is not used during leveling.

I just tried it on my centre origin machine (with two leadscrews, left and right of the bed), definitely both leadscrews get adjusted around the centre, ie the origin.

@fcwilt said in G32 doesnt save after True Bed Leveling:

Maybe the un-homing that occurs with the G28 Z causes the firmware to "forget" the adjustments made during bed leveling.

As far as I can tell, there is no adjustment, just that both the probed points are -0.64mm from the Z datum sent at the bed centre. There's nothing to 'forget'. One way to test would be to run G32 with no Z homing or G30 after, and see at what height the nozzle hits the bed in the centre.

Ian

-

The screen shots the OP posted shows there were adjustments. The fact that they were the same doesn't mean the firmware wasn't turning the steppers trying to get both sides to read "0".

It is pretty clear that, as you mentioned, the bed is simply higher in the center than at the edges. So re-setting the Z=0 Datum in the center is going to once again make the edges read low.

You got it right early on - good job.

Frederick

-

@fcwilt after several iterations and tryouts the problem is still there.

I can’t calibrate the first layer, the difference in the bed is very high… I dunno if it’s the compensation or something else. That’s why I was saying that the calibration wasn’t saved. I can post a picture of the printed 1st layer…

The mesh didn’t help btw @droftarts -

@johny Can you please at least post a picture of the bed mesh? As there's nothing else saved, ie there is not calibration with G32, it just levels the gantry with the information it gets from probing at the points you tell it to, there's very little else for us to go on. Maybe a picture of your machine that shows the whole bed, with an indication where it is probing. And yes, a picture of the first layer if you want.

Also, when you make a bed mesh, make sure any previous bed mesh is cancelled.

Ian

-

When I look at the screen shots you posted of the results from G32 I can see that it is making very nearly identical adjustments on both steppers.

That means for the two points being probed there is very little difference in Z height.

You observed that if you home Z after the leveling and then did the leveling again the results were the much the same.

That says to me the difference in Z height between the two points probed by G32 and the point probe by G30 differ by appx 0.64.

Given the location of those points it must be that your bed is "bowed" upward from the edges with the middle being appx 0.64 higher.

Please create a height map of, say, 10 x 10 and post a screen shot of what is looks like.

Frederick

-

@fcwilt

Screen of the 1st layer of a small cube. In the center it’s ok, 1 corner too far away and the other too close  image url)

image url) -

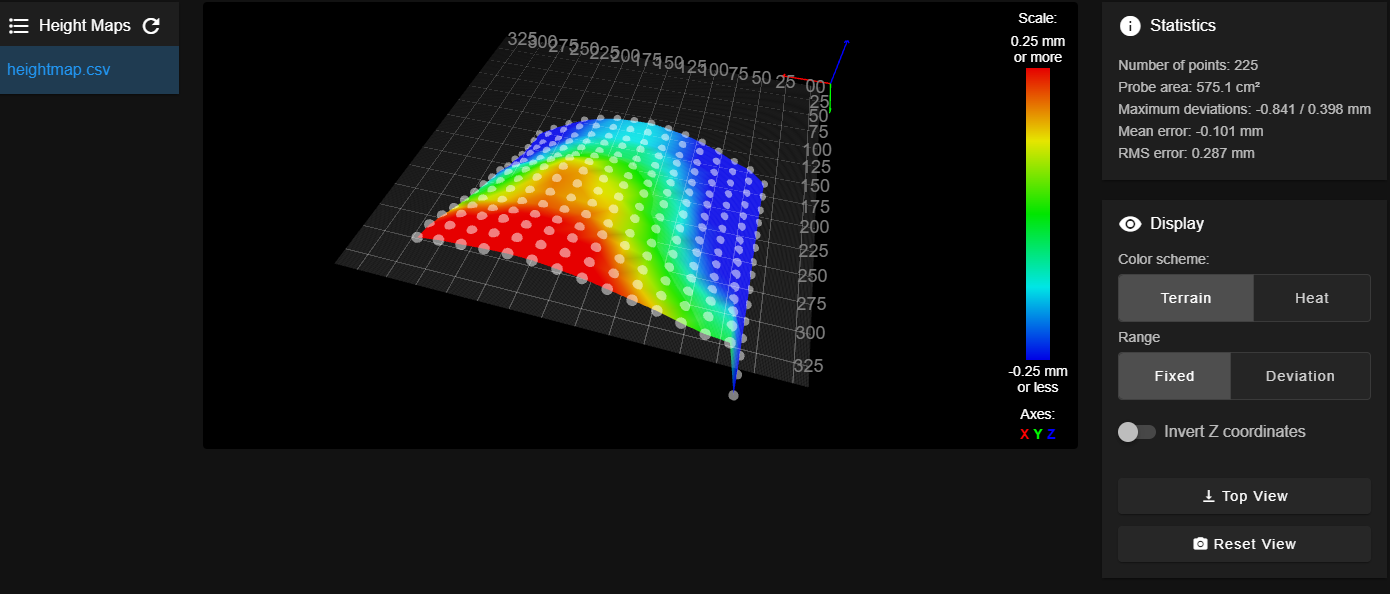

@droftarts the mesh

-

Your bed is not as flat as you would like.

And as you can see it does "bow" up in the middle which is consistent with G32 having no apparent effect when you follow it with homing Z.

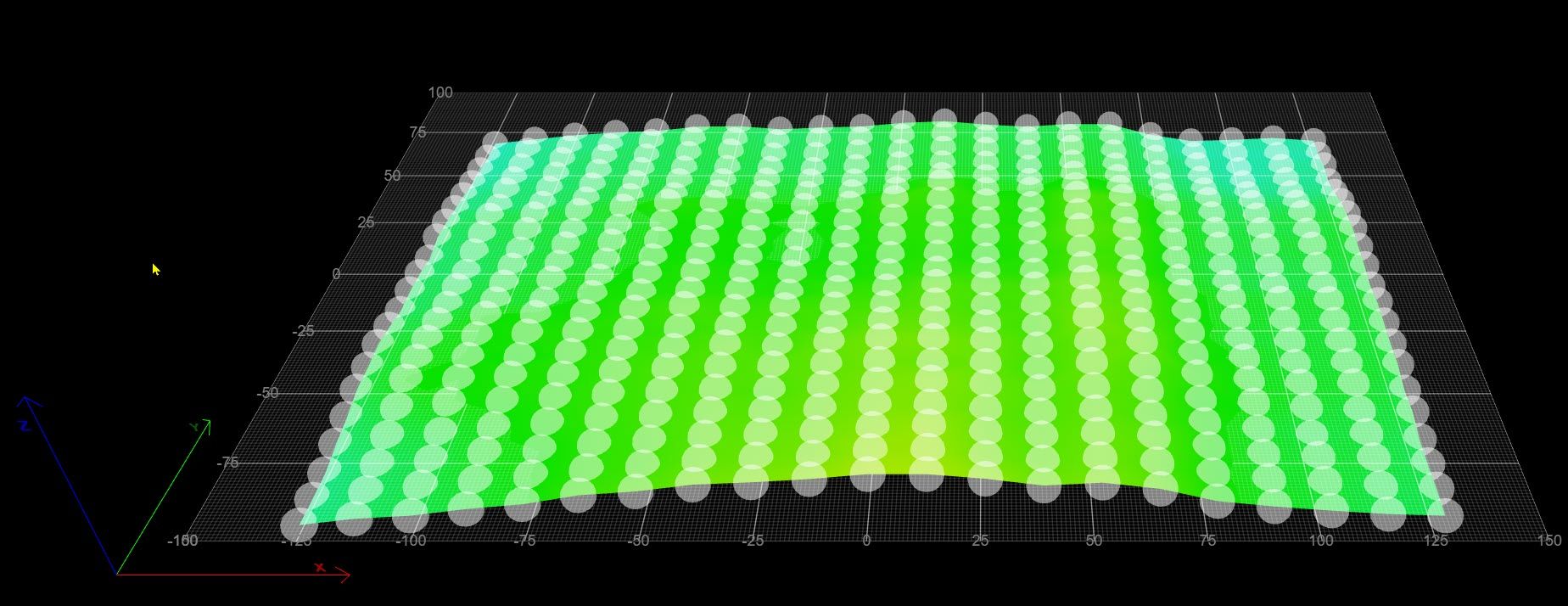

Here is a height map from one of my flatter printer beds:

Before creating the height map and before loading the height map you need to have set the Z=0 Datum using a G30 at the same XY location.

You Z homing code was doing that at the end which is fine as long as you home Z to set the Z=0 Datum.

And you should turn off any "baby-stepping" as well.

Are you printing with mesh compensation enabled?

Frederick

-

@fcwilt Thanks frederick.

Yes, i am printing with compensation enabled, dunno why it doesn't compensate :S The bed is awful, I don't know how can a thick AL plate have these waves, it's strange. Anyway the bed compensation should compensate for all of this no?

This is my starting gcode:

G31 P25 X31 Y4 Z0.50

G28

;M572 D0 S0.6 ;pressure advance

M190 S75

M375 P"heightmap.csv"

M109 S250 T0

G92 E0

;G1 E75 F100 extrude filament line

G0 X100 Y0 F9000 ; Go to front

G0 Z0.15 ; Drop to bed

G92 E0 ; zero the extruded length

G1 X40 E25 F500 ; Extrude 25mm of filament in a 4cm line

G92 E0 ; zero the extruded length

G1 E-1 F500 ; Retract a little

G1 X80 F4000 ; Quickly wipe away from the filament line

G1 Z0.3 ; Raise and begin printing.

G92 E0Note: it won't solve the problem but if i get a new bed... maybe its the PEI or the magnet stick below the PEI.

-

Just FYI you can load the height map with G29 S1 if you are using the default name as created by G29 S0.

Is your bed made from CAST ALUMINUM TOOL PLATE (CATP) ? Plain old aluminum sheet/plate is likely not going to provide the flatness you need. CATP is specified to have a certain flatness.

This start code you posted - where is it located? Did you enter it into the slicer somewhere?

Frederick

-

@johny said in G32 doesnt save after True Bed Leveling:

Anyway the bed compensation should compensate for all of this no?

With the probe homing in the middle, and setting Z0 at that point, the Z axis can't go below zero, because your Z limit is set by M208 to be

M208 X-10 Y0 Z0 S1 ; set axis minimaSet it to Z-1.

Ian

-

@fcwilt The bed is from AL plates cut in laser maybe i need to get it from another supplier, aliexpress?

The Gcode is the start Gcode on the slicer.@droftarts I understand what you are suggesting and i will add the line to let the Z go bellow zero 1mm but it wont affect this behaviour because as you can see in the 1 layer print the nozzle its already too close to the bed; i want to figure out why and how to solve it

-

@johny said in G32 doesnt save after True Bed Leveling:

The bed is from AL plates cut in laser maybe i need to get it from another supplier, aliexpress?

Being cut with a laser doesn't mean it will be flat.

Did you read about the CATP that I provided a link to? You can order a piece of CATP of the desired thickness and size from them. It takes a while but that have always proven to be reliable.

And there are other vendors that can do the same, such as these folks: cut2sizemetals

The Gcode is the start Gcode on the slicer.

Thanks.

the nozzle its already too close to the bed; i want to figure out why and how to solve it

That is likely caused by the Z trigger height parameter in G31 being a bit too large.

Frederick

-

@johny said in G32 doesnt save after True Bed Leveling:

in the 1 layer print the nozzle its already too close to the bed; i want to figure out why and how to solve it

M558 P5 C"^zprobe.in" H5 F300 T8000 A3 S0.03 ; set z probe to SuperPINDA\\ M557 X25:275 Y90:320 P15 ; probe from X= to , Y= to with a mesh spacing of mm G31 P1000 X23 Y5 Z-3.55Check your G31 Z probe offset: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing#calibrate-the-z-probe-trigger-height

Usually the G31 Z parameter is positive; a negative number means your probe is lower than the nozzle.Ian

-

@droftarts you are right the Z on G31 its 0.5 instead of -3.

@fcwilt i am in Europe its a very expensive to buy from USA

The correct G31 is Z0.5Any other anything else I can try to have the calibrated mesh working? maybe start with a new bed?

-

@johny said in G32 doesnt save after True Bed Leveling:

Any other anything else I can try to have the calibrated mesh working? maybe start with a new bed?

Do you mean a new bed, or a new bed mesh? It is easy enough to create a new bed mesh, just make sure that you cancel any existing bed mesh before you create a new one.

If you are homing Z in the centre, but it is printing too close at this point, then your Z height calibration isn't correct. Use baby-stepping during the print to get the height correct at this point; See https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing#fine-tuning-the-trigger-height

Fine tuning the trigger height

After you've done the procedure above, you can fine tune your G31 Z value to get a good first layer. During a test print, watch the first layer go down and adjust the Z position using the baby stepping function. If you have to move the nozzle closer to the bed, increase the G31 Z value by the amount of baby stepping used. If you have to move the nozzle farther away from the bed, decrease the G31 Z value by the amount of baby stepping used.The bed mesh should then correct for the rest of the bed, assuming that:

- Your probe is actually accurately measuring and creating the bed mesh

- If the bed is below the Z0 point, that you can actually reach it, by setting M208 Z-1 (or whatever it needs to be set to), as I said earlier.

Due to the shape of your bed, you're going to get parts that don't have a flat base if you print over the full area of the bed. RepRapFirmware tapers off the amount of bed mesh, reducing the effect over a number of layers until it is printing flat again. This is configurable with M376.

Ian

-

@johny said in G32 doesnt save after True Bed Leveling:

i am in Europe its a very expensive to buy from USA

I would think that Europe would have the same sort of vendors selling CATP cut to size.

Google may be able to find what you need.

Frederick

-

@droftarts That the issue, the print is ok in the middle but not okay in the corners, adjusting the Z trigger won't solve that problem.

-

@johny said in G32 doesnt save after True Bed Leveling:

That the issue, the print is ok in the middle but not okay in the corners, adjusting the Z trigger won't solve that problem.

True but setting Zmin to -1 may.

I've never had a bed shaped like yours (high in the middle) and with so much deviation. So I've never had to consider if Zmin = 0 was an issue. I need to test it.

You can just set Zmin to -1 and see if it solves the problems at the corners.

Frederick

-

@fcwilt Will try that thank you sir