thermistor noise

-

I have an odd issue with hot end temperature on one of my extruders and I could use some input on the issue.

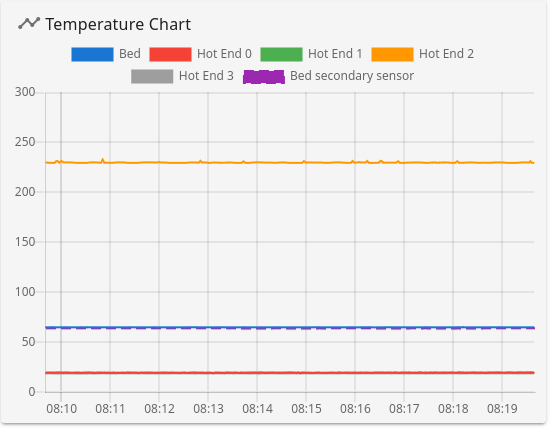

Looking at the 'hot end 2' temperature graph, one can see small 'blips'. Off hand, this doesn't seem like it should be much of a problem but I have had a couple of occasions where the blip was likely big enough to cause a heater fault and I would like to fix the issue.

I replaced the thermistor but the problem persists (the graph is from a print with the replacement thermistor). The thermistor wiring and heater wiring are running parallel to each other. The thermistor wire is not shielded.

Is it possible that these blips are generated from noise introduced to the thermistor wire from the heater switching on and off? Would a PT1000 sensor be just as likely to show blips or does the different resistance of the PT1000 make it less susceptible to noise? Would some kind of shielding around the thermistor wire and connected to the tool board ground be likely to fix the issue?While I could mess around with this, I am wondering if anybody else has seen this issue and has somehow solved the problem.

-

@jens55 said in thermistor noise:

Is it possible that these blips are generated from noise introduced to the thermistor wire from the heater switching on and off? Would a PT1000 sensor be just as likely to show blips or does the different resistance of the PT1000 make it less susceptible to noise? Would some kind of shielding around the thermistor wire and connected to the tool board ground be likely to fix the issue?

Its unlikely to be from the heater if you are using PWM rather than bang bang mode. Is it steady when the hotend is at temperature but not moving?

PT1000 are unlikely to help here.

shielding could help if it is interference being picked up from the wiring.

Doe you have a similar setup for your other two tools? have you tried swapping and seeing if the issue follows the tool or the wiring?

-

@T3P3Tony, I have a similar setup for 2 of the other tools. I have not tried to do anything with the other tools yet but will do so as soon as my current print job is finished. I will also test the hotend temperature when not printing at that time.

Thanks! -

@T3P3Tony, without printing, the graph is perfectly flat and the 'blips' are happening on the new tool as well.

-

@jens55 hmm that's with the tools hot, but not printing?

-

@T3P3Tony yes, the tool is parked but at operating temperature and the temperature graph is flat.

The new tool that is now printing has the blips on the temperature graph. -

@jens55 can you correlate that with a certain position of the print head?

-

@T3P3Tony, the object printed was about 80 mm cubed so there was only small x/y movement. Also, since a completely different tool had the same issue, I can't really see how position comes into the picture (since it can't be a loose connection for example). No, I can not correlate position and temperature blip.

For now I have increased my M570 parameters slightly to 15 degrees for 10 seconds and an R factor of 5 (up from 3). I am not quite clear about the R parameter but increased it a bit anyway. I would have thought that 10 seconds was a fairly large window where temperatures must deviate more than 15C and watching the actual temperature figure (ie not the graph) I did not notice a single temperature excursion of more than 15C that lasted anywhere near 10 seconds.I will also make a point of watching the temperature graph on my two other printers to see if they show the same behaviour.

I guess it is possible that the temperature faults I encountered were not related to the tiny 'blips' .....

-

Turns out that the noise is not present on a different printer. Watching the temperature reading when the noise blip happens shows about a 1.5C spike for less than maybe 1/2 a second. Since the temperature display update frequency is maybe 2 readings per second, the actual deviation could be bigger.

Very curious but that should not result in a temperature fault so I am assuming my previous heater faults were unrelated to these blips.

BTW, the board doing the blipping is a 6HC, the board that did not have the noise was a Duet2. -

I am sitting here and waiving a giant white flag ..... I give up

I tried out my third printer - totally flat temperature. I tried out my last tool on the printer with the noise issue - same thing. I wrapped a bare copper wire around the thermistor line and then wrapped that in aluminum foil and connected the bare drain wire to io2 gnd on my 1LC tool board ..... no change.

I upgraded the firmware from 3.5.0 rc2 to rc3 with no change noted (although I didn't expect a change)I have a nagging feeling that maybe the issue is related to the 1LC tool board and data being transferred on the CAN bus (since the two Duet2 printers do not have the issue). Of course I have nothing to back up that feeling ....

-

To confirm. on this machine, you have multiple tools, all of which display flat temperature graphs at any set temperature when they are not moving, but have these small blips when moving?

Are there any can bus errors reported?

(you can use M122 Bnn to get the reports from the boards)

-

@T3P3Tony .... yes, that is correct.

I don't know how applicable the following section of M122 is. The last print job was about 12 hours ago and when I do M122 now I get the following for the CAN section:

=== CAN ===

Messages queued 1009613, received 5566617, lost 0, errs 1, boc 0

Longest wait 4ms for reply type 6013, peak Tx sync delay 455, free buffers 50 (min 48), ts 339389/339388/0

Tx timeouts 0,0,0,0,0,0 -

@jens55 please also send M122 Bnn where nn is the address of the tool that was used in tat print

-

@T3P3Tony

Diagnostics for board 22:

Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-rc.3 (2024-01-24 17:55:14)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

All averaging filters OK

Never used RAM 2504, free system stack 83 words

Tasks: Move(3,nWait 7,1.7%,75) HEAT(2,nWait 6,4.5%,91) CanAsync(5,nWait 4,0.0%,55) CanRecv(3,nWait 1,1.4%,65) CanClock(5,nWait 1,0.3%,59) ACCEL(3,nWait 6,0.0%,53) TMC(2,delaying,45.4%,53) MAIN(1,running,94.5%,315) IDLE(0,ready,0.0%,27) AIN(2,delaying,61.8%,112), total 209.5%

Owned mutexes:

Last reset 18:57:01 ago, cause: software

Last software reset time unknown, reason: AssertionFailed, available RAM 3392, slot 1

Software reset code 0x0120 ICSR 0x00000000 SP 0x2000415c Task Freestk 129 bad marker

Stack: 00000544 00022ffc 00019b65 20003134 00016cff 20003134 000163d1 20000ed0 00000000 00000001 00008275 200071c8 200071c8 200071e0 00000000 20000f50 00011647 000223b8 00022474 00021ac8 00019b05 200071c8 200071c8 20000f50 000083ed 200071d8 000009c7

Driver 0: pos 0, 830.0 steps/mm, standstill, SG min 0, read errors 8, write errors 1, ifcnt 97, reads 64588, writes 24, timeouts 18, DMA errors 0, CC errors 0, failedOp 0x6f, steps req 0 done 49866182

Moves scheduled 397888, completed 397888, in progress 0, hiccups 29242, segs 36, step errors 0, maxLate 2 maxPrep 492, maxOverdue 4104, maxInc 2537, mcErrs 0, gcmErrs 0, ebfmin -1.00 max 1.00

Peak sync jitter -1/4, peak Rx sync delay 276, resyncs 0/0, no timer interrupt scheduled

VIN voltage: min 20.8, current 24.5, max 45.3

MCU temperature: min 37.6C, current 37.9C, max 52.7C

Last sensors broadcast 0x00000004 found 1 192 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 1398984, send timeouts 0, received 1831005, lost 0, errs 0, boc 0, free buffers 18, min 17, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 555, adv 35520/74673

Accelerometer: LIS3DH, status: 00

I2C bus errors 0, naks 3, contentions 0, other errors 0

=== Filament sensors ===

Interrupt 5726621 to 0us, poll 4 to 4256us

Driver 0: ok -

@jens55 thanks, doe snot look like CAN bus errors.

-

@T3P3Tony, does 'hiccups 29242' not indicate issues of some kind?

-

woops did not see the hiccups as was just looking at the CAN

-

@jens55 yes possibly. what steps/mm are you running your extruder at?

-

@T3P3Tony

M92 E25.3:51.875:51.875:51.875

Note that prints were done on the first 3 boards. The first tool uses a different extruder from the other two but blips showed up just as they did on the other tools.The above was from config.g, below is what I get back from sending M92 to the printer:

m92

Steps/mm: X: 100.000, Y: 100.000, Z: 3200.000, U: 30.578, E: 404.800:830.000:830.000:830.000First extruder is an LGX, others are BMG clones

-

@jens55 can you try using 16 microstepping with interpolation (it looks like you are using 256 microstepping?) that could well be the issue with the hiccups.