Can this be fixed ?

-

omg jay , after hours of trying to figure this out , i did a power cycle and its working

-

@Richard-F now to get the hot end stepper working , any idea what the driver number is on the tool board

-

@Richard-F

M569 P20.0 -

@jay_s_uk thanks

-

now im stuck getting the tool board drive to work .. lol

is there an error in the gcode

-

@Richard-F Rather than screenshots, can you please copy the text from config.g, and paste it into your reply, ideally within code tags (the

</>symbol on the posting format bar)? This makes it much easier to parse your config, and copy and paste parts that you need to change.I run a Mini 5+ and toolboard 1LC. Here's my config.g:

; Configuration file for RepRapFirmware on Duet 3 Mini 5+ WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0-rc.3 on Thu Mar 07 2024 14:57:09 GMT+0000 (Greenwich Mean Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"MinIan" ; set printer name M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; Wait a moment for the CAN expansion boards to become available G4 S2 ; wait for expansion boards to start ; Display M575 P1 S1 B57600 ; enable support for PanelDue M918 P2 E-4 F2000000 C70 R4 ; enable MKS Mini12864 ; LED Strips M950 E0 C"io3.out" T1 M150 E0 R60 U255 B0 P255 S3 F0 ; set LEDs for MKS Mini12864 ; M150 X2 R60 U255 B0 P255 S3 F0 ; set LEDs for MKS Mini12864 - RRF 3.4 and earlier ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S0 ; disable Telnet ; Smart Drivers M569 P0.0 S0 D3 V0 ; physical drive 0.0 goes forwards M569 P0.1 S1 D3 V0 ; physical drive 0.1 goes forwards M569 P0.2 S1 D3 V0 ; physical drive 0.2 goes forwards M569 P0.3 S0 D3 V0 ; physical drive 0.3 goes forwards M569 P0.4 S1 D3 V0 ; physical drive 0.3 goes forwards M569 P121.0 S0 D3 V2000 ; driver 121.0 goes forwards (extruder 0) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.0 Y0.1 Z0.2:0.4 ; set drive mapping M906 X1000 Y1000 Z800 ; set motor currents (mA) and motor idle factor in per cent M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X160 Y160 Z800 ; set steps per mm M566 X300 Y300 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X9000 Y9000 Z600 ; set maximum speeds (mm/min) M201 X2000 Y2000 Z20 ; set accelerations (mm/s^2) ; Extruders M584 E121.0 ; set extruder mapping M906 E1000 ; set extruder driver currents M350 E16 I1 ; configure microstepping with interpolation M92 E397 ; configure steps per mm M566 E300 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E600 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; Axis Limits M208 X-116:100 Y-128:107 Z0:180 ; set minimum and maximum axis limits ; Endstops M574 X2 P"io1.in" S1 ; configure X axis endstop M574 Y1 P"io2.in" S1 ; configure Y axis endstop M574 Z0 ; configure Z axis endstop ; Probes M558 K0 P8 C"121.io0.in" H5 F600:120 T6000 A5 ; configure unfiltered digital probe via slot #0 G31 P500 X30 Y0 Z1.03 ; set Z probe trigger value, offset and trigger height ; Mesh Bed Compensation M557 X-85:85 Y-85:85 P5 ; define mesh grid ; Accelerometers M955 P121.0 I14 ; configure accelerometer on board #121 ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B3988 ; configure sensor #0 M308 S1 P"121.temp0" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; configure sensor #1 ; Heaters M950 H0 C"out0" T0 Q50 ; create heater #0 M143 H0 P0 T0 C0 S120 A0 ; configure heater monitor #0 for heater #0 ;M307 H0 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #0 ;M307 H0 R0.314 K0.219:0.000 D9.83 E1.35 S1.00 B0 ; 3.5.0-rc2 tune 20/12/23 M950 H1 C"121.out0" T1 ; create heater #1 M143 H1 P0 T1 C0 S300 A0 ; configure heater monitor #0 for heater #1 ;M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 for JHead M307 H1 R2.295 K0.299:0.342 D6.80 E1.35 S1.00 B0 V11.9 ; 3.5.0-rc3+ tune 4/4/24 Hemera with V6 ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"121.out1" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"121.out2" ; create fan #1 M106 P1 S0 B0.1 H1 T45 ; configure fan #1 ; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous T0Ian

-

@Richard-F Your M563 to define the tool is incorrect. Should be:

; Tools M563 P0 S"REd" D0 H0 F0D0is the 'first defined extruder drive'. It doesn't take the CAN address.If you send

M98 P"config.g"it should report errors in your config.g. I suspect if you did this, it would show an error on that line.Ian

-

@droftarts said in Can this be fixed ?:

M98 P"config.g

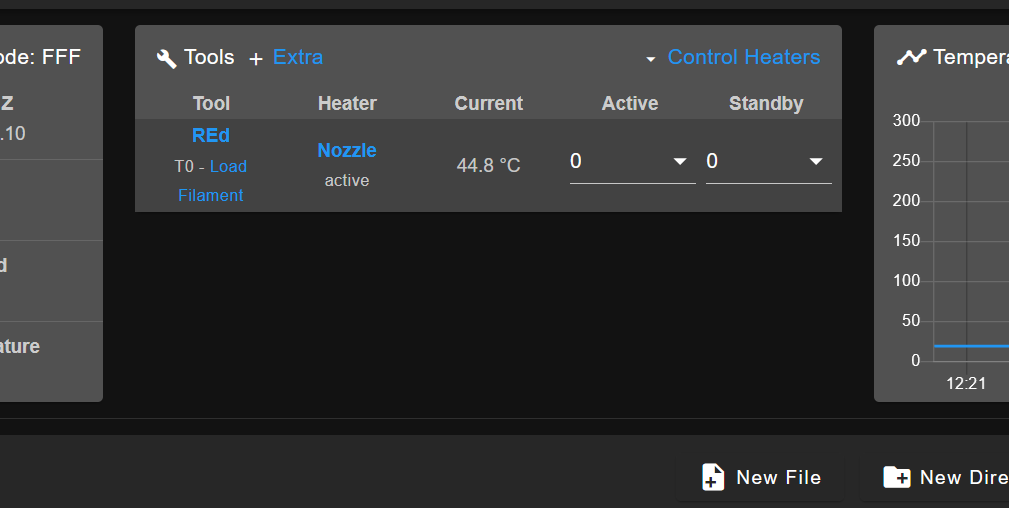

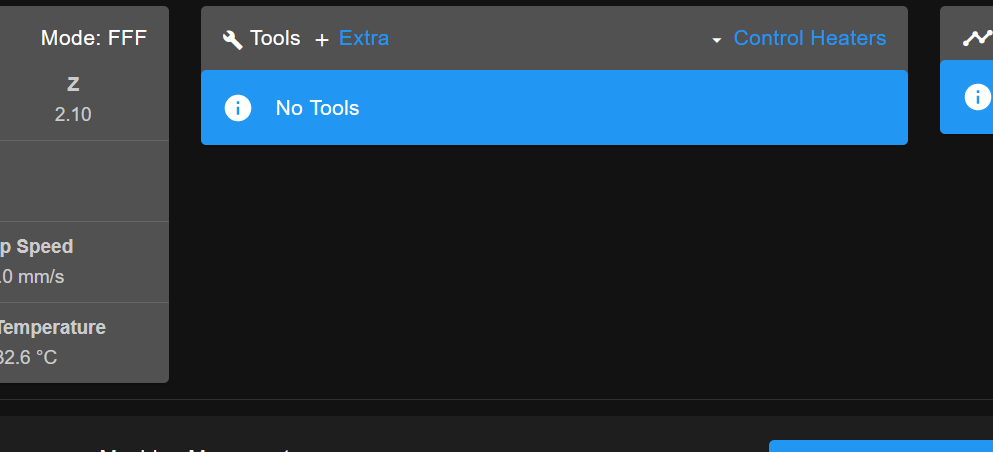

thanks Ian , i now have a tool , but no moment on E drive

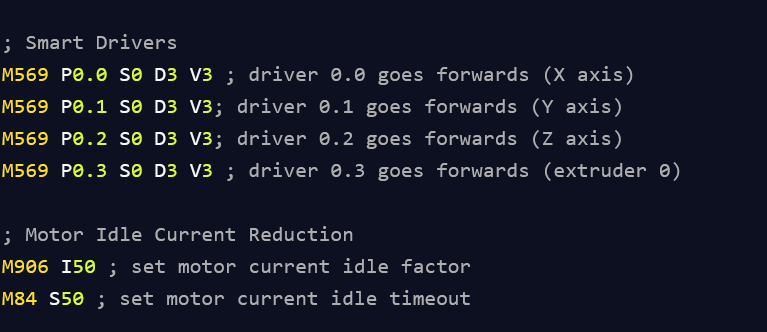

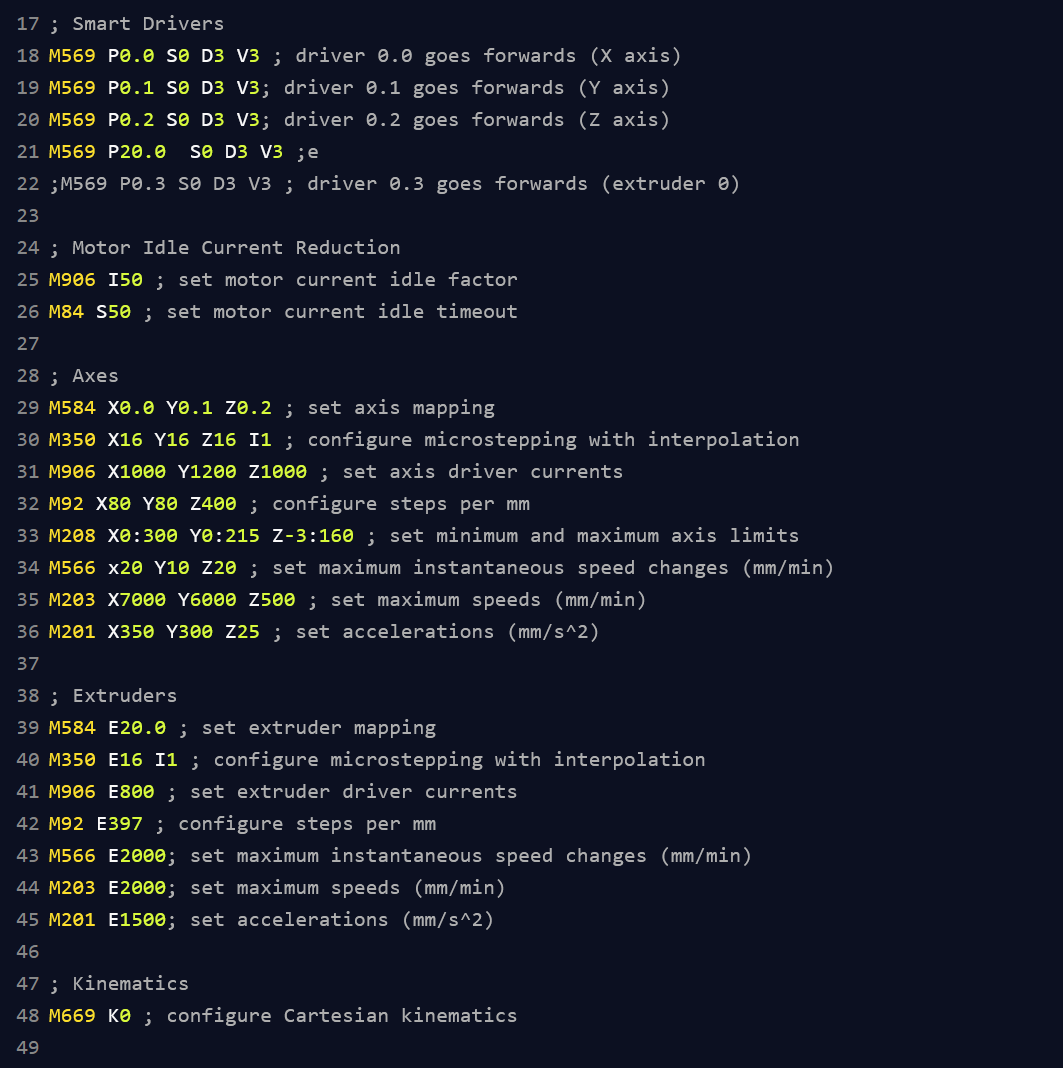

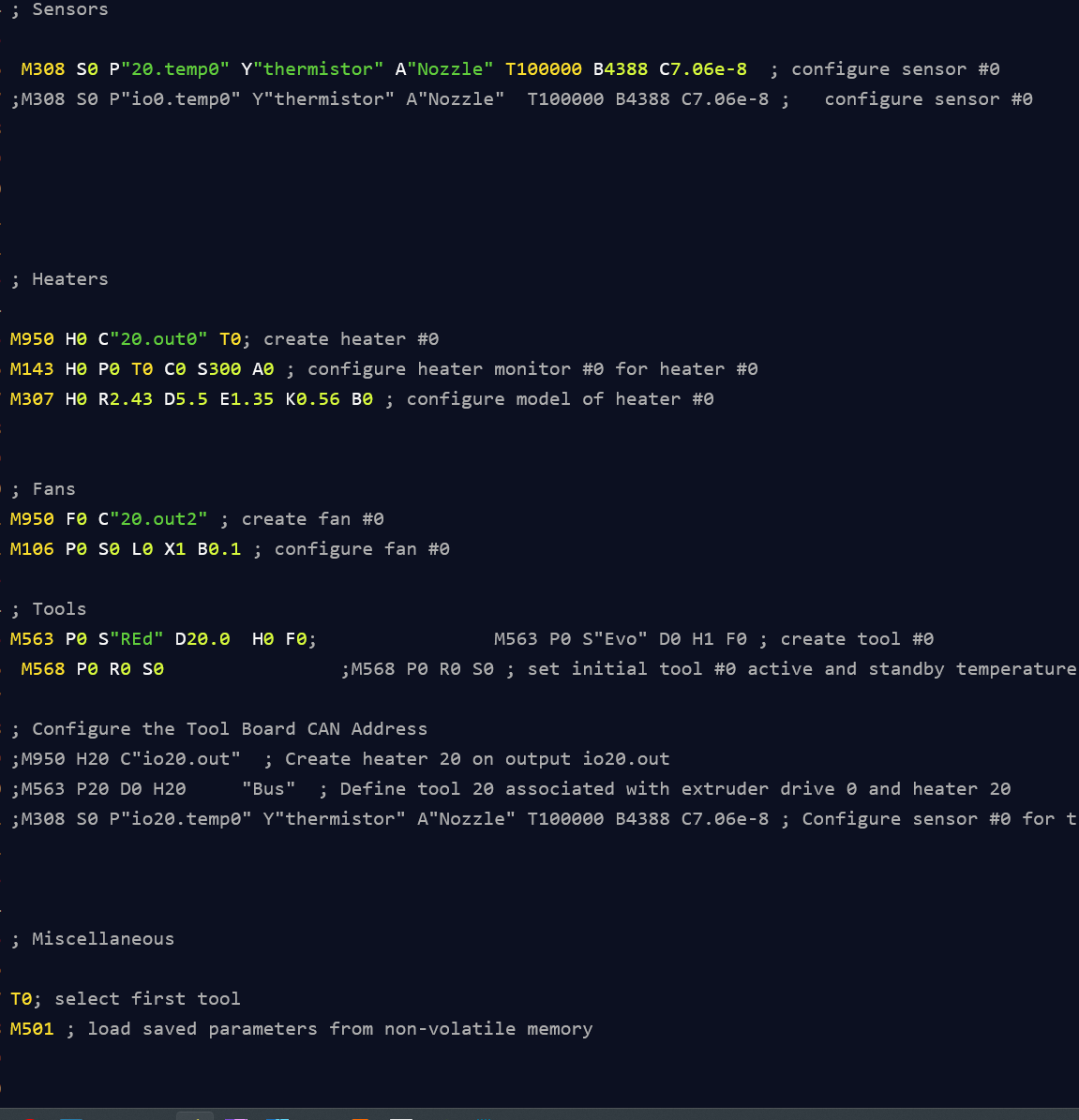

my gdode looks ok , it might be a hardware isssue ```; Configuration file for RepRapFirmware on Duet 3 Mini 5+ WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0-rc.3 on Thu Mar 14 2024 13:43:02 GMT+0000 (Greenwich Mean Time) ; General M550 P"Duet 3" ; set hostname ;M911 S19.8 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; Network M552 S1 M587 S"HeX" P"Spyder30" ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; LED Strips ;M950 E0 C"io1.out" T2 ; configure LED strip #0 ; Smart Drivers M569 P0.0 S0 D3 V3 ; driver 0.0 goes forwards (X axis) M569 P0.1 S0 D3 V3; driver 0.1 goes forwards (Y axis) M569 P0.2 S0 D3 V3; driver 0.2 goes forwards (Z axis) M569 P20.0 S0 D3 V3 ;e ;M569 P0.3 S0 D3 V3 ; driver 0.3 goes forwards (extruder 0) ; Motor Idle Current Reduction M906 I50 ; set motor current idle factor M84 S50 ; set motor current idle timeout ; Axes M584 X0.0 Y0.1 Z0.2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X1000 Y1200 Z1000 ; set axis driver currents M92 X80 Y80 Z400 ; configure steps per mm M208 X0:300 Y0:215 Z-3:160 ; set minimum and maximum axis limits M566 x20 Y10 Z20 ; set maximum instantaneous speed changes (mm/min) M203 X7000 Y6000 Z500 ; set maximum speeds (mm/min) M201 X350 Y300 Z25 ; set accelerations (mm/s^2) ; Extruders M584 E20.0 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M906 E800 ; set extruder driver currents M92 E397 ; configure steps per mm M566 E2000; set maximum instantaneous speed changes (mm/min) M203 E2000; set maximum speeds (mm/min) M201 E1500; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ;---------------------------------------------------------------------------- ; Probes ;M558 K0 P5 C"io2.in" H15 F100 T6000 ; configure analog probe via slot #0 ;G31 P500 X-30 Y-25 Z1 ; set Z probe trigger value, offset and trigger height ; Define probing grid parameters ;M557 X20:290 Y10:300 S100 ; Define a probing grid from X10 to X190 and Y10 to Y190 with a 20mm spacing between points ;---------------------------------------------------------------------------------------------------------- ; Endstops M574 X1 P"!io5.in" S1 ; configure X axis endstop M574 Y1 P"!io6.in" S1 ; configure Y axis endstop M574 Z1 P"!io0.in" S1 ; configure Z axis endstop ; Mesh Bed Compensation ;M557 X25:175 Y25:175 S40:40 ; define grid for mesh bed compensation ; Sensors M308 S0 P"20.temp0" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; configure sensor #0 ;M308 S0 P"io0.temp0" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; configure sensor #0 ; Configure sensor #0 for the nozzle on temp input 0configure sensor #0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; Heaters M950 H0 C"20.out0" T0; create heater #0 M143 H0 P0 T0 C0 S300 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #0 ; Fans M950 F0 C"20.out2" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 ; Tools M563 P0 S"REd" D0 H0 F0; M563 P0 S"Evo" D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ;M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ;M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Configure the Tool Board CAN Address ;M950 H20 C"io20.out" ; Create heater 20 on output io20.out ;M563 P20 D0 H20 "Bus" ; Define tool 20 associated with extruder drive 0 and heater 20 ;M308 S0 P"io20.temp0" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; Configure sensor #0 for the nozzle on temp input 0 ; Miscellaneous T0; select first tool M501 ; load saved parameters from non-volatile memory -

@Richard-F said in Can this be fixed ?:

it might be a hardware isssue

It hasn't been so far! How are you trying to test the motor? Are the Extrude and Retract buttons greyed out on DWC? The tool needs to be active, and the hot end has to be up to temperature. You can 'cold extrude' (ie test without filament) by sending

M302 P1(see https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m302-allow-cold-extrudes)If that doesn't work, check the wiring of the stepper motor to the connector. Check the motor phases are in pairs, and that the pairs are next to each other when the connect to the toolboard, see https://docs.duet3d.com/en/User_manual/Connecting_hardware/Motors_connecting

Ian

-

@droftarts thanks ian , i can turn heater on , and im using dwc extrude . button , no signs of life , i have the wires connected correct and test phase pairs . i dont know if theres a way of get info from the driver to see if thats damaged .

or i might just have to run a wire back to the mini 5ive been at it for 20 hours now . lol

-

@Richard-F Your extruder config:

; Extruders ... M566 E2000; set maximum instantaneous speed changes (mm/min) M203 E2000; set maximum speeds (mm/min) M201 E1500; set accelerations (mm/s^2)I have a Hemera (with V6, not Revo) and my extruder settings are very different. I think M566 E2000 is way too fast, and could be causing the motor to stall before it even gets a chance to move. M201 acceleration is rather high too. Have you used these values before?

Here's mine, which has been printing fine recently, albeit not very fast (mostly up to 60mm/s):

; Extruders ... M566 E300 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E600 ; set accelerations (mm/s^2)Ian

-

@droftarts thanks ian , I've used your values , yes it was working fine from the mainboard , i guess the lower values give the gears less stress

-

@Richard-F So it's working now?

Ian

-

@droftarts no , i can put my ear next to the motor and nothing . if my gcode looks good , next ill solder stepper wires onto the tool board , no luck there ill just have to use the driver from the main board . Maybe one of the duet guys knows of a command to check driver for errors .. anyway im of to bed, I've been up all night .. Just when you think it will be a simple job lol

thanks for your help Ian

-

@Richard-F Check the firmware version on the mainboard and toolboard, they need to be the same. Send

M122andM122 B20and post the responses.Ian

-

@droftarts said in Can this be fixed ?:

M122

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.0-rc.3 (2024-01-24 17:56:48) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: LZWJ4-8096U-D65J0-40KML-2N03Z-7ZUUZ Used output buffers: 1 of 40 (19 max) Error in macro line 11 while starting up: Failed to add SSID to remembered list: WiFi module is disabled === RTOS === Static ram: 103200 Dynamic ram: 120308 of which 0 recycled Never used RAM 15052, free system stack 202 words Tasks: NETWORK(2,nWait 7,14.9%,204) HEAT(3,nWait 6,0.0%,372) Move(4,nWait 6,0.0%,243) CanReceiv(6,nWait 1,0.0%,796) CanSender(5,nWait 7,0.0%,337) CanClock(7,delaying,0.0%,349) TMC(4,nWait 6,0.8%,102) MAIN(1,running,83.3%,427) IDLE(0,ready,0.0%,30) AIN(4,delaying,0.8%,260), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:15:51 ago, cause: power up Last software reset at 2024-04-16 15:47, reason: User, Gcodes spinning, available RAM 15076, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 MCU revision 3, ADC conversions started 951995, completed 951995, timed out 0, errs 0 MCU temperature: min 21.8, current 32.2, max 32.4 Supply voltage: min 23.5, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/76/0, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 50067, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 15, reads 50066, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 50067, writes 14, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 10, reads 50070, writes 10, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x6f Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 10, reads 50072, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-04-16 16:33:42 Cache data hit count 1770644905 Slowest loop: 35.35ms; fastest: 0.16ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.8ms, write time 29.7ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 331672ms, bed compensation in use: none, height map offset 0.000, max steps late 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 9, completed 9, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 3], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000803 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 4806, received 11456, lost 0, errs 1, boc 0 Longest wait 2ms for reply type 6053, peak Tx sync delay 471, free buffers 26 (min 25), ts 4760/4759/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 43.91ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 -

@Richard-F can you grab an output of

M122 B20as well? -

M122 b20 Diagnostics for board 20: Duet TOOL1LC firmware version 3.3RC2 (2021-05-11 14:59:50) Bootloader ID: SAMC21 bootloader version 2.8 (2023-07-25) Never used RAM 3292, free system stack 0 words Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.2%,81) CanAsync(notifyWait,0.0%,66) CanRecv(notifyWait,0.0%,79) CanClock(notifyWait,0.0%,66) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,2.8%,57) MAIN(running,92.0%,349) IDLE(ready,0.0%,26) AIN(delaying,4.9%,62), total 100.0% Last reset 00:01:59 ago, cause: software Last software reset at 2024-04-16 16:33, reason: AssertionFailed, available RAM 3292, slot 0 Software reset code 0x0120 ICSR 0x00000000 SP 0x20004094 Task x> Freestk 136 ok Stack: 00000544 00023174 00019cb5 20003044 00016e33 20003044 00016505 200071c8 00000001 00000001 0000828d 200071c8 200071c8 00000000 20000f50 00000020 00011311 200071c8 00008611 200071d8 000ed7d1 000ed7d1 434d0b16 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 Driver 0: position 0, 397.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 32, reads 59584, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 10, peak Rx sync delay 632, resyncs 1, no step interrupt scheduled VIN: 24.2V MCU temperature: min 42.6C, current 42.6C, max 44.4C Ticks since heat task active 227, ADC conversions started 119222, completed 119220, timed out 0, errs 0 Last sensors broadcast 0x00000001 found 1 232 ticks ago, loop time 0 CAN messages queued 1470, send timeouts 0, received 619, lost 0, free buffers 36, min 36, error reg 0 dup 0, oos 0, bm 0, wbm 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 0, other errors 0 -

@Richard-F said in Can this be fixed ?:

Duet TOOL1LC firmware version 3.3RC2 (2021-05-11 14:59:50)

That'll be it! Upload the 1LC firmware from the 3.5.0-rc3 release. Or the zip package rc4 release to update everything to that: https://github.com/Duet3D/RepRapFirmware/releases/tag/3.5.0-rc.4

Edit: Strange that it has a later bootloader version than firmware version:

Bootloader ID: SAMC21 bootloader version 2.8 (2023-07-25)

Ian

-

@droftarts yes i download the bootloader earlier , im not all that sure what all the different files are

is it the bin file i need ?