Z offset using probe . getting it right . help needed

-

Sorry everyone , i have 2 threads open . but i only come on here when ive been trying myself to figure out for hours

it seems there are lots of offset options

its a hall , ( metal bed detect probe ) . im also using it as the home z endstop .

its about 2mm up from nozzle

so i dont know what is the best M-code to use . i carnt seem to get a good offest without the point data flying off the grid..

either way , high or lowM106 P1 S230 ; Turn on fan 0 at full speed M307 H0 R2.430 K0.560:0.000 D5.50 E1.35 S1.00 B0 V0.0 M307 H1 R0.130 K0.150:0.000 D10.00 E1.35 S1.00 B1 M558 K0 P8 C"20.io0.in" H2 F200000 T1000 ; configure metal proximity sensor via slot #0 G31 P500 X20 Y-20 Z5 M851 Z3.1 ; Set Z probe offset .. M109 S0 T0 M593 F40 ; impit shaper , F= HZ ; Z probe parameters ;G31 K0 P500 X20.0 Y-15.0 Z3 ;G10 P0 L20 X0 Y0 Z10.1 ; HIGHER = DOWN . LOW = UP -

@Richard-F I wouldn't mess around M581 just set the offset correctly using G31

-

@Richard-F does this not work for you? https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing

Ian

-

@droftarts thanks IAN , i will look at that "duet doc " Me having dyslexia , it's hard to take in information from text . But i will try my best

-

@Richard-F The important concept about Z-offset is that it the same for every location on the bed of your printer. It's purpose is to tell the firmware the distance between the nozzle and the bed when the Z-probe "triggers". This way, when your slicer tells the printer to go to something like Z=.2mm for the first layer, it will know where that is.

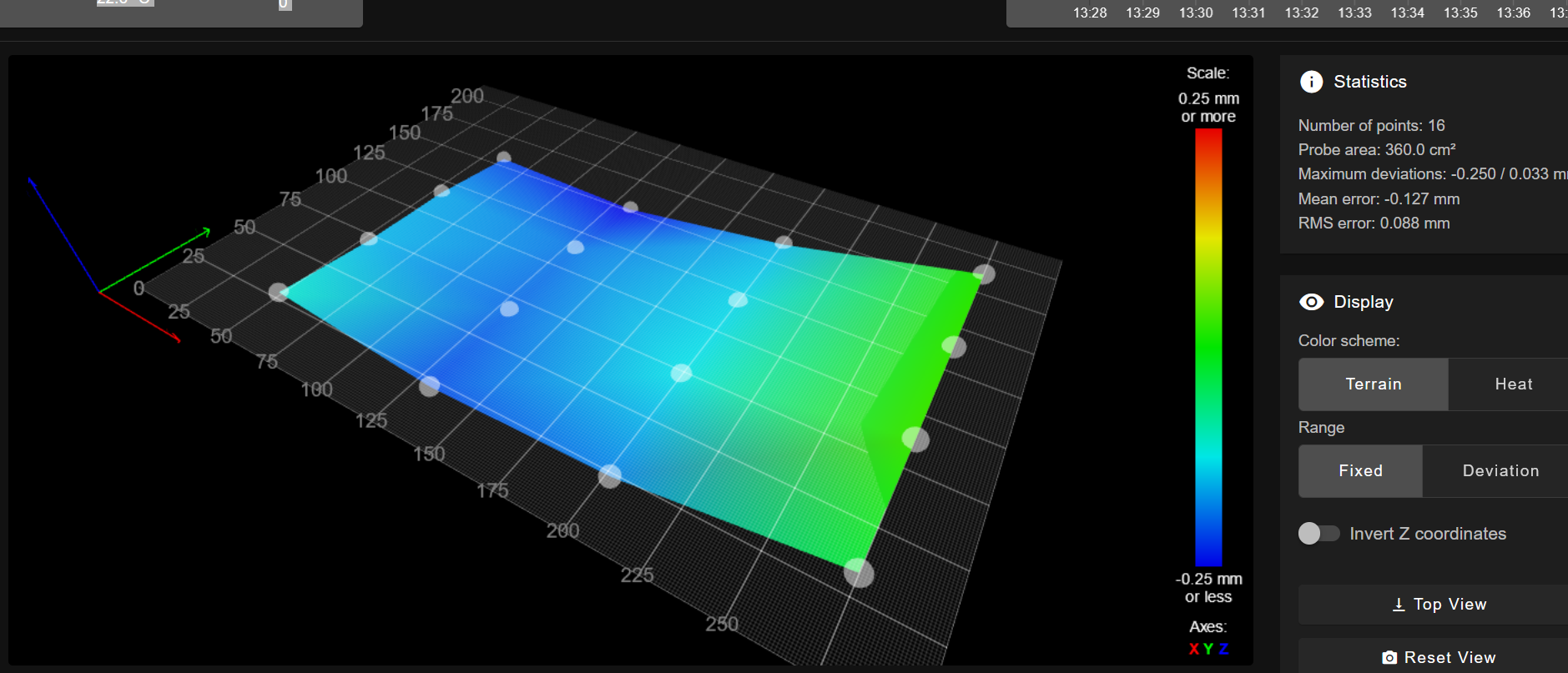

The picture you included is a visual representation of how flat and level your print surface is. The probe measures the distance to the bed at multiple locations (16 places, in your picture). Once the mesh has been created, the firmware will use the data to make small adjustments in Z to keep the tool at the right height above the bed.