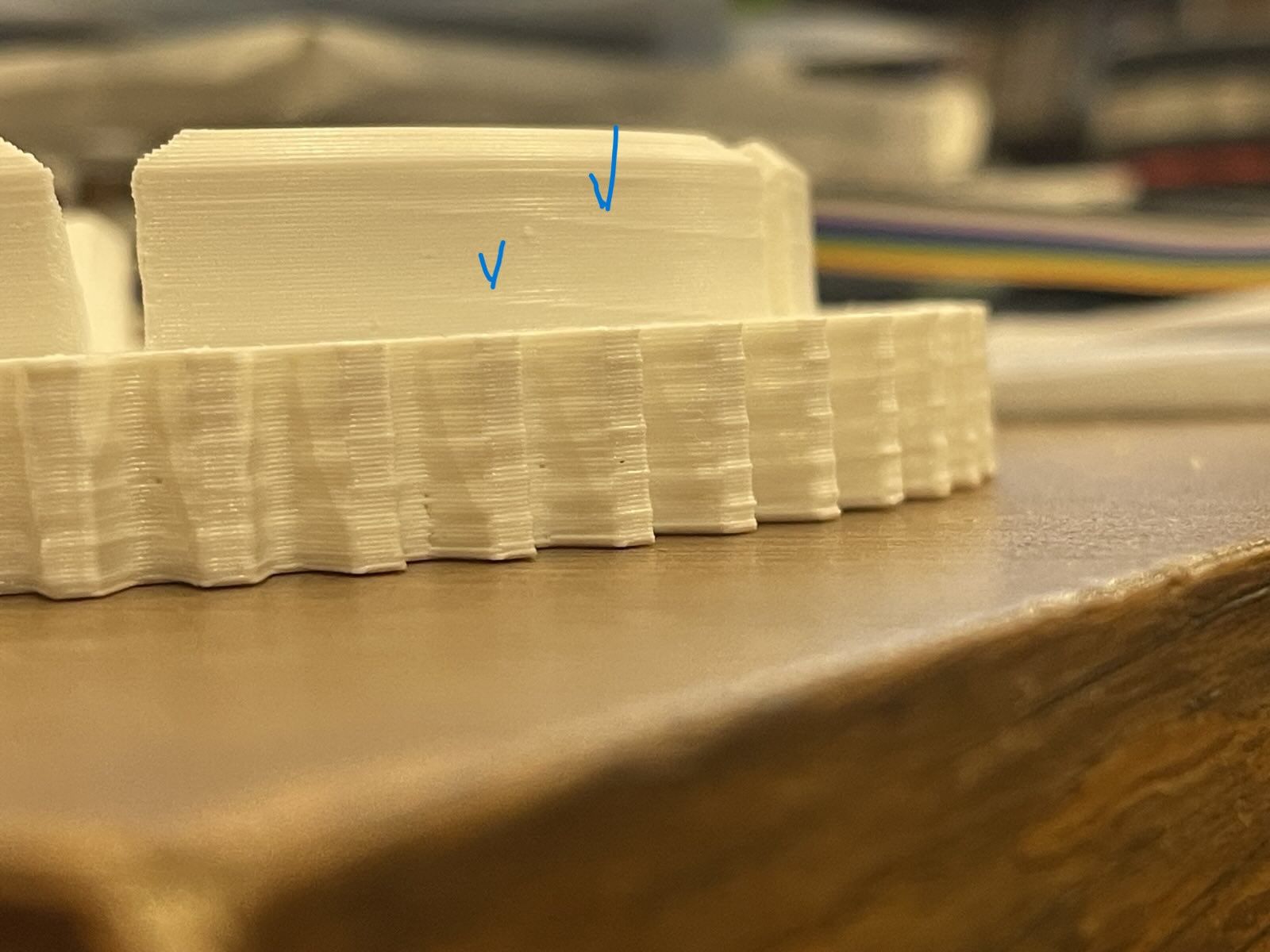

diagonal line on print causing layer shifting?

-

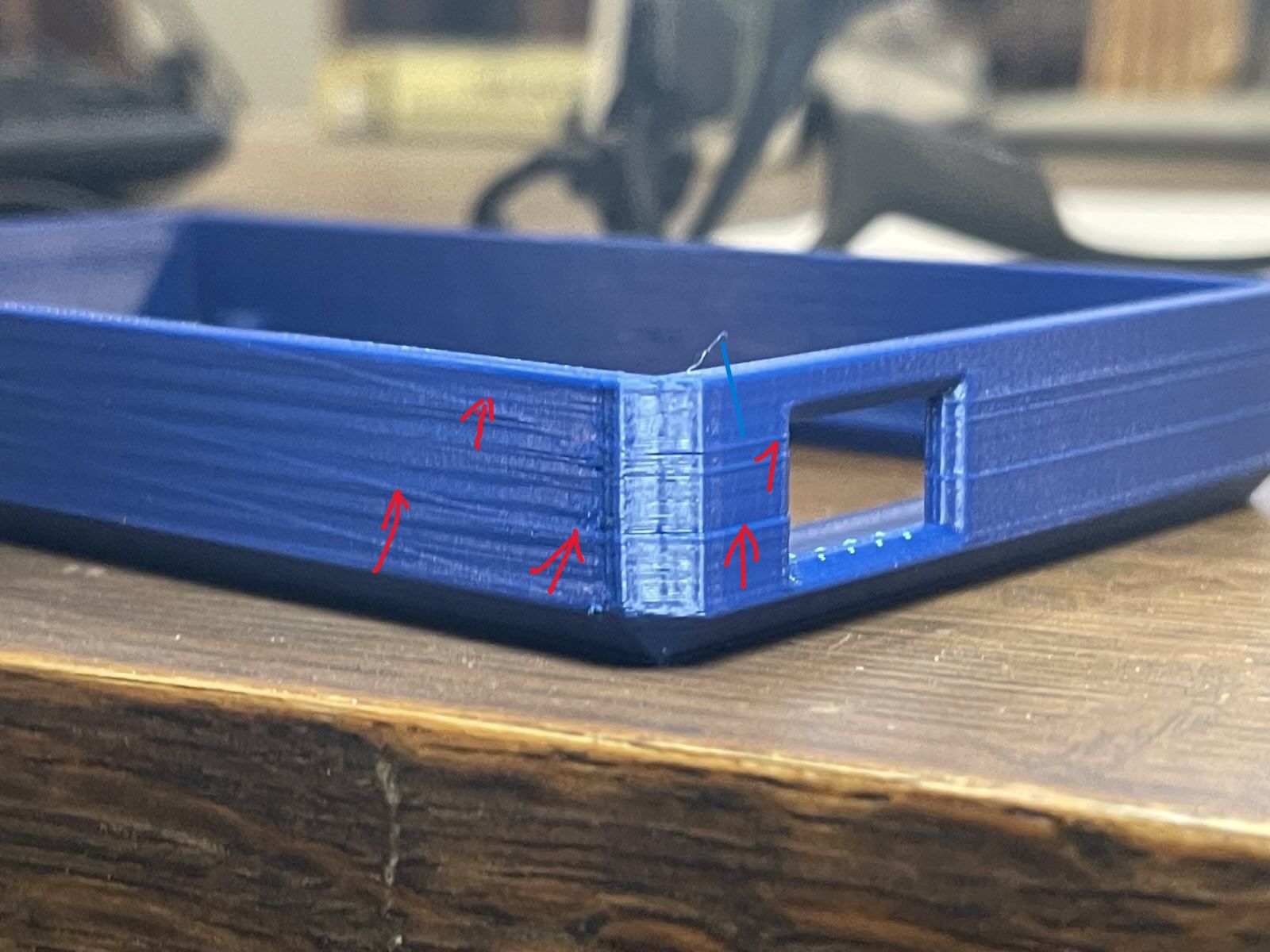

Do you guys have any idea what is causing theses lines. they seem to travel diagonal on the y axes and then leave a small level layer shift only on the x axes. It is on a modded ender 3 with duet 5 mini.

I am not sure whether to blame hardware or software.

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Wed Oct 12 2022 17:23:19 GMT-0500 (Central Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 3 Ultra" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes b M569 P0.4 S0 ; physical drive 0.4 goes backwards M671 X-50:270 Y0:0 S10 ; define dual driven z-axis M584 X0.4 Y0.1 Z0.0:0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.6755 Y80.00 Z400 E406.86275 ; set steps per mm M566 X400 Y400 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E3600.00 ; set maximum speeds (mm/min) M201 X500 Y500 Z200.00 E500 ; set accelerations (mm/s^2) M906 X1300 Y1400 Z700 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X205 Y220 Z260 S0 ; set axis maxima M206 X0 Y20 Z0 ; Endstops M574 X1 S1 P"io5.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io5.in M574 Y1 S1 P"io6.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io6.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y-20.701 Z3.895 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X10:200 Y10:210 s60:60 ; define me ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S180 ; set temperature limit for heater 0 to 180C M308 S1 P"temp1" Y"pt1000" ; configure sensor 1 as PT1000 on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S450 ; set temperature limit for heater 1 to 450C M308 S2 P"temp2" Y"thermistor" T100000 B4092 ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out2" T2 ; create chamber heater output on out2 and map it to sensor 2 M307 H2 B1 S50 ; enable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S100 ; set temperature limit for heater 2 to 100C ; Fans M950 F0 C"out3" Q150 ; create fan 0 on pin out3 and set its frequency M106 P0 C"part fan " S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"hotend fan" S1 H1:2:0 T45 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"mother bourd" S1 H1:2:0 T45 ; set fan 2 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Copperhead" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S22 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool M955 P0 C"spi.cs2+spi.cs1" ; all wires connected to temp DB connector, no temperature daughterboard M572 D0 S.6 M556 S100 X-0.2 ;skew adjust ;M593 P"EI3" F40 ; use ZVD input shaping to cancel ringing at 40.5Hz M376 H10 M304 P32.8 I.706 D111.9 M575 P1 S1 B57600;screen code -

What is your extruder setup like?

-

My go-to place to start debugging this kind of thing is the slicer. For the diagonal lines, is there something happening on every layer, but at a different location? I use PrusaSlicer and it has the ability to show you the exact path it's creating for the gcode on each layer. I can often see something like a seam, or the first part of a line on a new layer, or maybe a scarf joint (latest Prusa feature). Sometimes it's something on a line that's not the outer perimeter.

In your gear picture, it looks like you have some X an Y shifting of the print bed as a function of the Z position. This can make the repeating waviness. I had a problem like this on my home built printer and I found some wobble in the Z-lead screws was pushing my bed around. I added something called an "oldham coupling" ( https://www.amazon.com/gp/product/B0C55RRFF6 ) which allows the lead screws to wobble some without imparting any X or Y forces. It solved the Z-related movement for me.

-

@Phaedrux

It is a bmg with Bowden. -

@mikeabuilder

If forgot to say it only happens on larger models so I think the z axes can be ruled out.

I use cura so maybe i should try Prusa slicer. Thanks for your ideas! -

Try printing a cone shape. I think it will show it exagerated.

-

@53581

Bang-bang control on the bed could cause kind of stripes.

As far as i can see, your config. may have been created for an older firmware. The heater parameters have changed with 3.4.

I don't know if that really makes a difference.

But I would change to PWM-control and autotune the bed heater and the tool.

Please also post the content of config-override.g as the parameters should be stored there..... -

@DIY-O-Sphere I did not even realize I had bang bang on the bed! That would fit with the idea that the layer time effects it. I printed that gear in vase mode, and it was very good. I also tried a Prusa slicer, no change.

-

@DIY-O-Sphere - Can you post the gcode file for the gear?

-

This post is deleted! -

I opened the gcode file in PrusaSlicer and I don't see anything that looks like it would cause those shifts. The layer thickness is .3mm and each layer in the gcode is following the same path, with a variation in the 3rd decimal. This means I don't think there is anything coming in from the slicer X and Y positions or extrusion rate.

One thing I wonder about (because I'm not a spiral vase user) is whether there might be any effect on printing due to the very small Z moves with each new segment extruded. Can your Z stepper resolve the typical .001mm move on each segment? What's the smallest Z step your printer can do? I assume that if a z move is smaller than the printer resolution, RRF will accumulate the Z moves unti a full step (or micro-step) is used to "catch up". But I don't think this is the cause because if it was, then I'd expect to see the sane defect in the same place on every layer.

Which brings me back to the possibility of the bed shifting slightly during printing. I'd look at the defects on opposite X and Y sides to see if the defect shows matching shifts.

And unrelated to the print defects, I think you might want to look at the tooth generator, assuming this is an involute gear profile. The gcode path looks like an involute at the outboard part of the tooth, but has a little kink about half-way to the root of the tooth. It should be a nice rolling path (an involute) .

-

The Ender 3 runs on v-rollers. You might have a flat spot on a roller or some dirt collection on the rails?

If it was real level shifting, you'd also see it on the inside, but it looks OK there. -

"What's the smallest Z step your printer can do?" To be honest I am not sure! they are just stock ender 3 stepper Moters. If it is something mechanical, I am not sure how it is consistent enough to travel up the side of the part like that.

-

@Phaedrux

I think these like pretty good. -

I was thinking something a lot larger/taller than that so you can start to see any repeating patterns.

Try a taller cylinder and conical cylinder in vase mode.

-

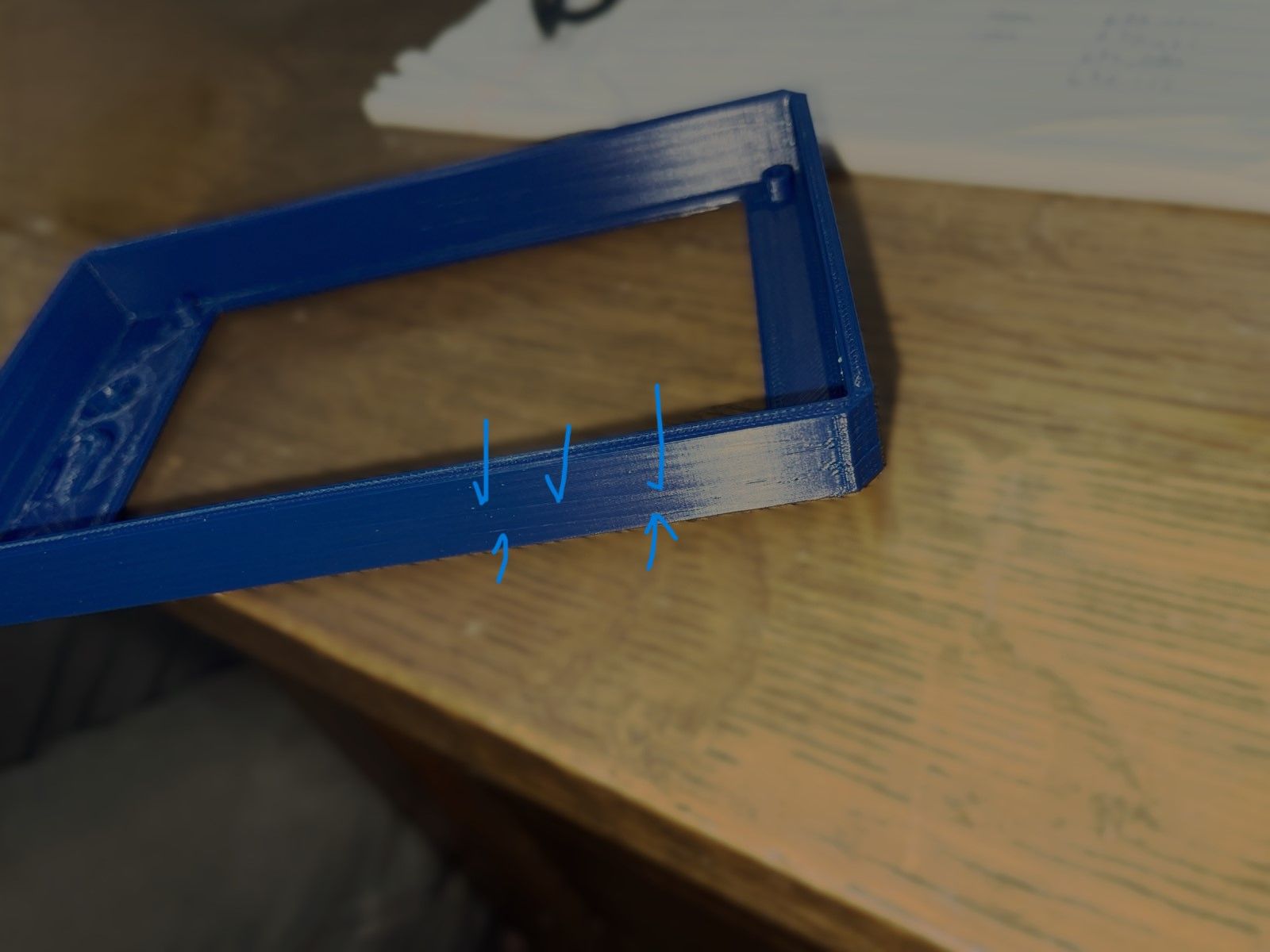

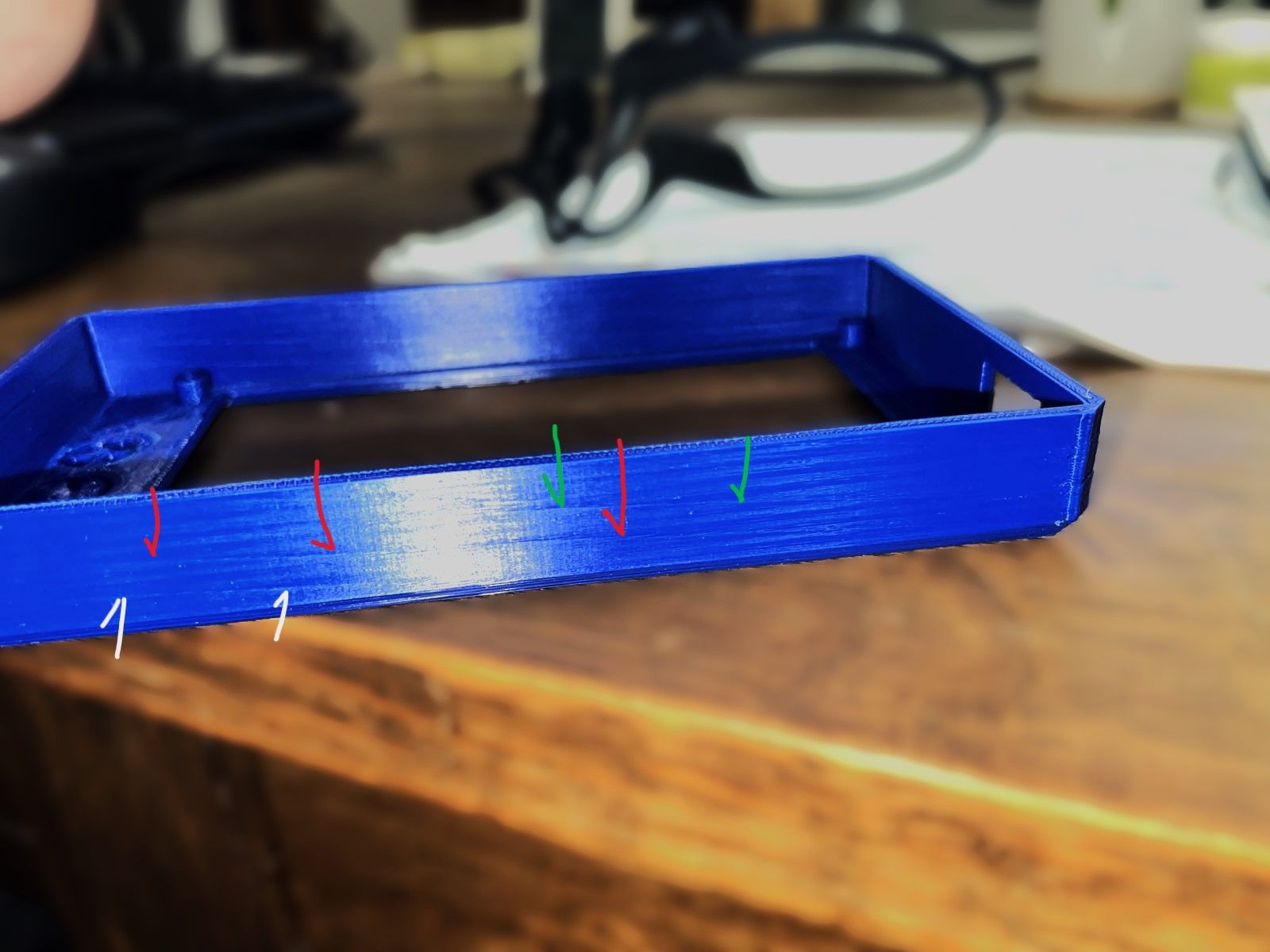

After more testing I Think I am getting z binding on both sides. This would explain why the artifacts do not travel straight through the part but rather make separate patterns on the wall closest to their respective sides while leaving the center looking ok.

-

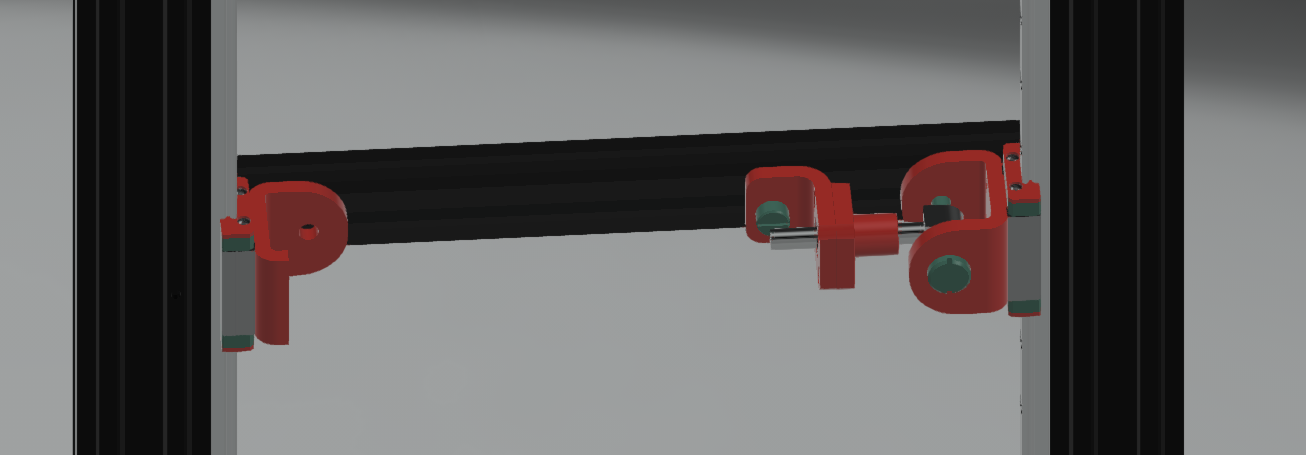

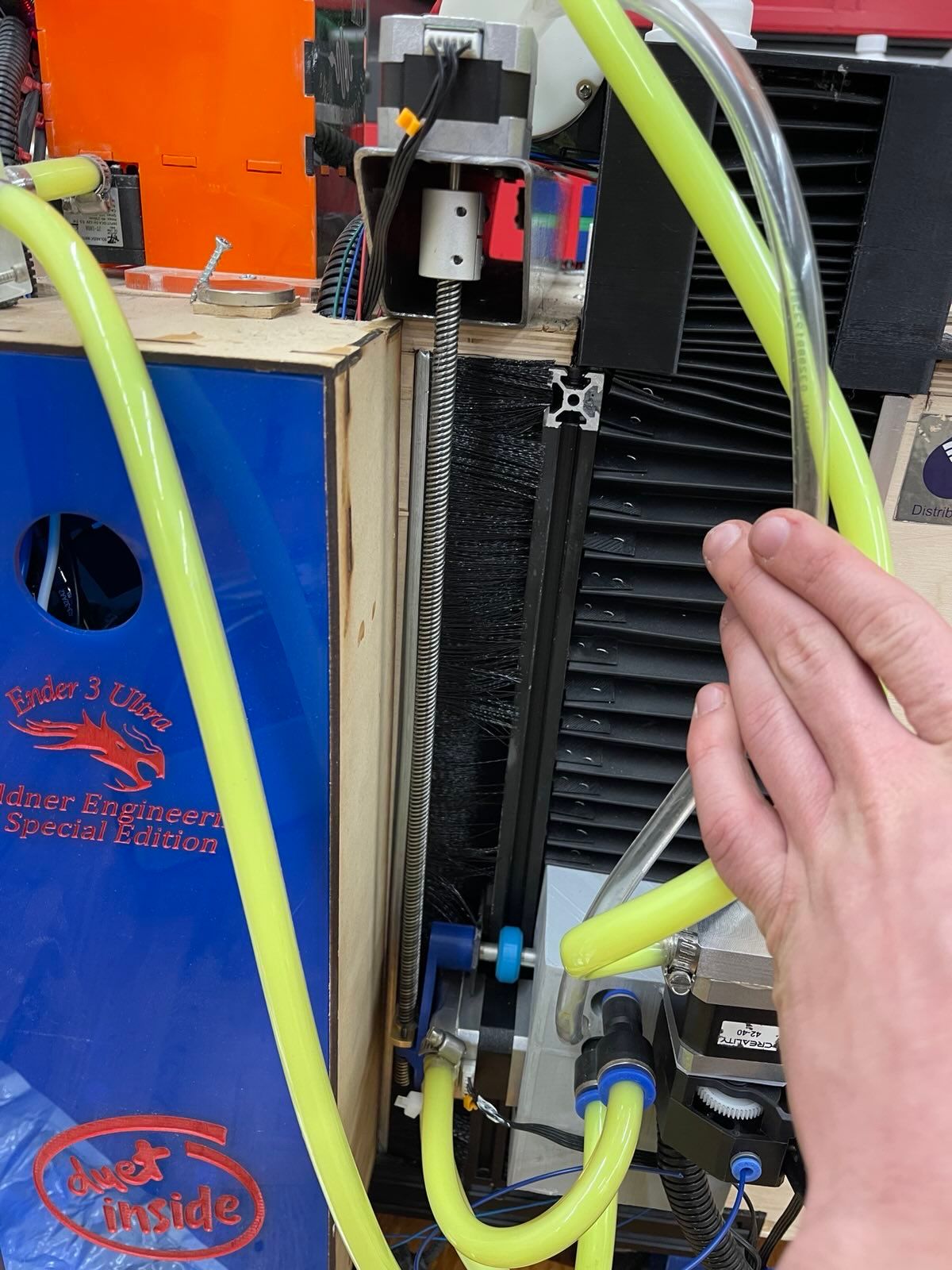

So the way I have my z steppers hooked up the whole x axes hangs on it rather than pushing on it, does this make a difference?

this is how I plan to fix it I will a add linear bearings for the blue lines and then somehow mount the linear bearing cars to the x in a way that it can pivot so it can move independently.

this is how I plan to fix it I will a add linear bearings for the blue lines and then somehow mount the linear bearing cars to the x in a way that it can pivot so it can move independently. -

@53581 said in diagonal line on print causing layer shifting?:

a add linear bearings for the blue lines and then somehow mount the linear bearing cars to the x in a way that it can pivot so it can move independently.

To avoid axis' binding, you need to fix one side while the other side can "float" in one direction to compensate thermal expansion.

-

@o_lampe I have been wondering about a core xz mod for it.

However I do not want to lose auto tramming Z! Do you have any thoughts on that?

However I do not want to lose auto tramming Z! Do you have any thoughts on that? -

@o_lampe Something like this?