E3D Roto + Duet Roto Toolboard - Stepper motor stalling

-

@elmoret Can confirm, E3D testing is always a "worst case" recommendation. The max motor amperage is only if they are pushing ultra high flow high pressure, in a 50+C heated chamber, for extreme lengths of time.

You may want to raise your amperage as that would give you more force available. -

@elmoret This problem started while printing ABS but I have since reverted to testing with PLA with the same results, the motor keeps stalling after 15-20 minutes of printing when coming from a cold start and sooner on later prints.

@Notepad I have also tested with the absolute max current E3D recomends, 0.6A peak with the same result, I think anything beyond that might risk damaging the coils.

I will open a case with E3D to be sure the motor is not damaged at this point.

-

the motor keeps stalling after 15-20 minutes of printing when coming from a cold start and sooner on later prints.

Looks like a classical heat creep. Initially, this might have happened at high temperatures when printing ABS. Then, with PLA, remainders of the ABS can partially block the filament path so that the melt zone expands upwards…

Have fought with that before, cleaning the filament path had only a temporary effect. In the end, I had to swap both the nozzle and heat barrier. Finally, I improved the cooling (of the cold end of my hot end

), which was the root cause of my problem.

), which was the root cause of my problem. -

@infiniteloop I hadn't thought of that, I will try a fresh nozzle and upgrade the fan, thanks for the suggestion

-

@infiniteloop I managed to try a fresh 0.4 nozzle and replaced the original extruder cooling fan with an slightly bigger one, still not working.

Also, I saw on the TMC2240 datasheet that Spreadcycle can compensate to some degree for the back EMF coming from the stepper, switched to that mode but didn't work as well

More ideas are appreciated before I take the leap and go for an smart orbiter.

-

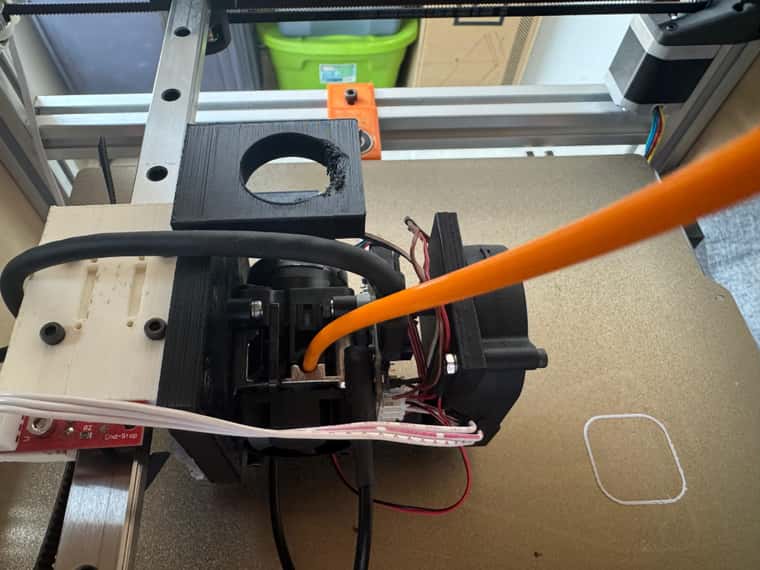

Can you share some photos of the extruder setup to help with context?

-

@Phaedrux For sure

-

No sock on the nozzle?

How are you cooling the Roto's heatsink? Looks quite boxed in there.

-

@elmoret this particular nozzle didn't have a sock. The heatsink fan can be seen in the third picture from top to bottom

-

I managed to try a fresh 0.4 nozzle and replaced the original extruder cooling fan with an slightly bigger one, still not working.

So you didn’t touch the heat break? From you photos, I cant’t get a clue. Could you describe the setup? I mean, is it all-metal, has it a PTFE tube all down to the nozzle …

-

@arturolaz All genuine E3D nozzles have socks. And yes, I can see the fan, I can also see that the area around the heatsink, that the exhaust air would be flowing through, is pretty blocked.

-

@infiniteloop No, I didn’t touch the heatbreak as this is a Revo nozzle there is no PTFE tube inside just the nozzle tightened all the way in into the Roto extruder. The PTFE tube coming from the top barely gets inside the assembly without reaching the hobbed gears.

@elmoret it is a nozzle from the early beta testing of the revo system when those were shipped without sock, so, for your point, it is genuine. There is no air path blocked aside from the front where the toolboard is supposed to be installed and the back for the mounting system, did you mean that?