Extrusion not always starting correctly?

-

Hi All,

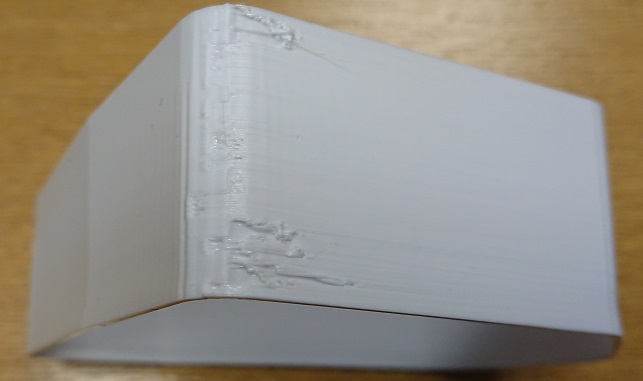

I've a few issues in the picture below but I am most concerned about the messy start to the extrusion tracks on a few of the layers. This is a tall skirt printed to reduce curling on some chunky parts. The main concern I'd like to ask about is the poor start to the extrusion on the occasional layer. Weird thing is it isn't always poor.

Other issues I am aware of is that it does suffer ghosting and issues from the toothed side of the belts running over smooth bearings.

I think it is something to do with one of the following but welcome other's experience before I dive in on the tweaking!

; Filament and Retraction

M207 S1.8 R0.05 F3600 Z0.0 ; Firmware retraction (s = advance retract, r additional advance.

M200 D1.75 ; Set extruder 1 to 1.75mm filament

M572 D0 S0.05 ; Enable pressure advanceMaterial: PETG

Temp: 220C

Speed: 40 or 60mm/s (not sure which slic3r parameter controls skirt speed. Will look at gcode when I get a chance.)

Firmware: 1.21

Hardware: Duet v0.6 -

Didn't see it manifest as severely in today's build but thought the pictured could be a less severe version of it?

Could it be that when I have really severe resonance or vibration the first bit of extrusion doesn't start well?

Edit: 0.2mm layers

-

Another resent occurance with PETG. Running duet ethernet now.

-

What size nozzle are you using?

I have run into this with a 0.8 mmm nozzle on a volcano heater block. The fix is to add add additional unretract volume after retraction. The problem with that is that the effect will vary with the travel distance (time?) between the retraction and the unretraction. Cura has a plugin to make the unretract priming a function of the travel distance, which should fix it.

I also see gaps in extrusion after travel moves without retraction, such as when the nozzle is printing infill. I haven't figured out what to do about that yet.

-

@doctrucker said in Extrusion not always starting correctly?:

I think it is something to do with one of the following but welcome other's experience before I dive in on the tweaking!

; Filament and Retraction

M207 S1.8 R0.05 F3600 Z0.0 ; Firmware retraction (s = advance retract, r additional advance.

M200 D1.75 ; Set extruder 1 to 1.75mm filament

M572 D0 S0.05 ; Enable pressure advanceI've not used firmware retraction, so can't really comment, other than to guess that if the issue were a retraction issue, it would be consistent across layers.

Do you see these issues if you eliminate pressure advance? How about if you use the slicer's retraction and filament settings?

John

-

@mrehorstdmd Sorry for the delay, I hadn't put a follow on this thread! Sounds like this is getting close to a feature request then. I'm using a 0.4mm nozzle on a standard E3D V6 hot end direct driven by a titan. Thanks for tje tip, I'll run a few tests with additional unretract.

-

@johnocfii said in Extrusion not always starting correctly?:

I've not used firmware retraction, so can't really comment, other than to guess that if the issue were a retraction issue, it would be consistent across layers.

Do you see these issues if you eliminate pressure advance? How about if you use the slicer's retraction and filament settings?

John

I'll try running without pressure advance in the next build. I've not got around to tuning it since swapping back from a bowden system and just dropping in values seen on other threads for direct extrusion systems.

I've used firmware retraction since swapping to volumetric extrusion so I don't need to tell both the slicer and the machine exact filament diameters, and I can also rerun old gcode just by updating the machine's filament diameter setting rather than having it set. Personal preference really.

-

I have only used one type of PETG and thats the CF filled version from 3Dxtech and "extra" after retraction is a must. On a Titan Aero or Aqua with .4 nozzle 1mm of retraction with .5-.75 on restart is good. I haven't been able to find the right setup using pressure advance yet so those are the settings without it. I get similar results of starving on restart if I don't use the .5-.75. Just an FYI I also run the bed at 90c (40c enclosure) and 260 on the HE which results in excellent printing and bonding other than that occasional turd that falls off the nozzle