Yet another cast aluminum plate topic...

-

@wyvern said in Yet another cast aluminum plate topic...:

My question now is do I use the 8 mounting holes that was stock, or just 4?

The FT5 mounting holes are trying to make up for a flimsy bed. With a stiff bed a 3 point system is ideal. Don't worry about drilling accuracy, it really won't matter as long as you're in the ballpark. It's far easier to get 3 points level than 4 points.

-

I'm thinking of forgoing the counter sunk holes, I think using them may cause things to be over restrained when it heats up.

Instead I'm thinking of using slightly oversize holes and aluminum washers (the washers are countersunk and the bottoms are flat) so long as tension and weight are enough to keep it from wriggling around.

-

@wyvern I've done a 3 point countersunk mount on mine. It's not up to the level of a kinematic mount, but it hasn't seemed to have a noticeable impact on first layer printing.

Originally I had intended to have two of the holes along the side to keep the pivot point along the center of the bed, but then there was a bit of instability, so I went with two corners and the opposite center. I was also going to use bolts with round heads to allow for some adjustment, but the screws were expensive and when the M4 bolts worked fine I didn't bother.

One corner is set static as reference, and the other two are pitch and roll.

Drilling wasn't too bad. It just took some patience. I used progressively larger bits and slowly reamed out the holes. I used a drop of oil each time which helped keep the chips from getting everywhere if nothing else.

-

I see. The stock setup on mine is a tapered screw and countersunk hole, so they fit flush- but it's unnecessary when the nozzle doesn't come anywhere near them.

I haven't worked with this type of Aluminum, it's supposed to be easier to work with than Mic6, I have a really nice IR hand drill, or, access to a really tired POS drill press, I just hate drilling crooked holes.

Is it really that hard of an alloy?

-

@wyvern I just used a hand drill. I oversized the holes slightly to give the bolt heads some space to self adjust. I used a piece of tape to judge the depth of the hole to leave 1mm at the bottom. I didn't find the MIC6 hard to drill.

-

Ok good, I've drilled through some serious steel that might as well been diamond, nightmare fuel when you only have one shot to do it right.

I will just pick up some new bits.

Looking forward to a bed that's flat, my machine is unusable ATM.

-

@wyvern ATP-5 is harder than MIC-6, I'd say take your time, use lubricant when drilling and as mentioned use stepped sizes. I'm going with a kinematic mount for mine, at least I'm going to try to. My plate is a bit thicker so I have a little more material to work with.

Clinton Aluminum has good article online that discusses the differences between ATP-5 and MIC-6 but the forum marked it as spam for some reason.

-

Thanks,

I was reading that last night, but half asleep.

If I'm reading specs correctly, Mic6 is stiffer, and slightly more conductive.

ATP is slightly more elastic, less prone to taking a set and grows slightly less than Mic6 under heat. -

@wyvern that's kind of what I got from it as well, along with the ATP being a little harder. Given the sizes we're dealing with I don't think the nominal difference in stiffness will have an impact.

-

So the next question, 1/4" glass on top of the 3/8" cast aluminium or something like BuildTak or PEI directly on the aluminum? The glass seems flat but when I apply glue I can feel ripples in it. I haven't actually done anything with the cast plate yet, the heater should be here tomorrow, but the surface feels smooth.

-

@TLeTourneau, you will find different opinions on that. I prefer to use a removable glass plate so that I can swap print beds easily. The main benefit is that if a print sticks too well to the bed, I can put the bed+print in the fridge or freezer to help it to come free. Also I can swap plates and start a new print after one has finished, without waiting for the bed to cool down (which can take a while if you are using a thick aluminium plate). Finally, I can experiment with different print surfaces (plain glass, PEI, PrintBite etc.) on top of the glass plates.

The disadvantages of using glass on top is that you need to have space at these margin for bed clips (which loses a little print area unless you included a margin in your bed design), and the temperature on top of the glass will be lower than on the aluminium by 5 to 10C.

If you do use glass then I suggest 4mm thick not quarter inch. Ordinary float glass is usually flatter than toughened glass.

-

Because you use cast aluminium there is no need for a glass on top in my opinion (that just increases the heat up time and weight)

-

@tletourneau You'll get dozens of different opinions on this. IMO, there is no right or wrong - it's just personal preference. Like DC42, I prefer the removable glass option and for the same reasons. I use 6mm thick float glass (1/4 inch) because my bed is on the large side, and it's fine. Just allow for the top surface of the glass to be about 2 deg C less than the aluminium under it.

Edit. Because aluminium is a soft metal, it's not too difficult to scratch or dent it. Especially if you print directly on to it and resort to using a scraper or some such to remove a part. So I'd highly recommend that you put something on top of it, whether that be semi-permanent of easily removable.

-

@deckingman

I will use a magnetic printbed like Ziflex or easy-peelzy (but they are not that good for ABS because of temperature resistance of the magnets)

I backed them back on kickstarter but didn't receive my item yet

EDIT: Ziflex can be heated up to 100°C before loosing its power. -

Well the plate and heater are installed, now to run a mesh and see what it looks like. Here are some pictures.

Here's the cast aluminum plate:

Here is a view of the frame I made to mount the plate:

Here is the front with the plate on the mount:

Here is a closer look at the front mount:

Here is the rear left mount:

And the rear right mount:

I also installed linear rails on the X and Y axis's:

I just thought I'd share.

-

@tletourneau run a detailed G29, let's see how flat that sucker is.

-

Well this is strange to me, any thoughts on how to adjust this?

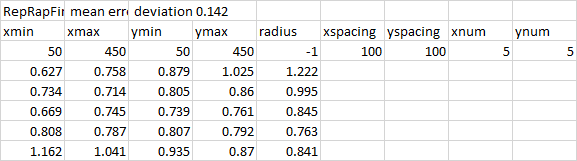

Here is the CSV data:

RepRapFirmware height map file v2 mean error 0.847 deviation 0.142 xmin xmax ymin ymax radius xspacing yspacing xnum ynum 50 450 50 450 -1 100 100 5 5 0.627 0.758 0.879 1.025 1.222 0.734 0.714 0.805 0.86 0.995 0.669 0.745 0.739 0.761 0.845 0.808 0.787 0.807 0.792 0.763 1.162 1.041 0.935 0.87 0.841This is using a BLTouch, the Z-probe settings are:

; Z-Probe ; BLTouch M574 Z1 S2 ; Set endstops controlled by probe M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch M558 P9 H5 F100 T6000 A10 R0.3 S0.01 B1 ; Set Z probe type to bltouch and the dive height + speeds G31 P25 X59 Y-12 Z.92 ; Set Z probe trigger value, offset and trigger height M557 X50:450 Y50:450 S150 ; Define mesh grid -

Did you remeasure your z offset and manually level the bed first?

-

Thanks for the reply! I did measure my Z offset using the method in the wiki. I thought I leveled my bed... I'll level it again to be sure and run it again.

-

@tletourneau

Dat thicc boiIs that 1/2 inch?