Hey guys,

after countless hours and multiple iterations, I would like to present to you the D-PATCH (Delta Printer with automatic tool changing). To my knowledge there is no Delta Printer available with tool-changing. I have been working on it for over 2 years (started in March 2018) and I am proud, that it is now a reality.

As you can see it’s not completely finished yet, because the actual tool changer is missing, but is in the making. A prototype is existing already.

Stats about the Printer:

Print volume: 300x300mm

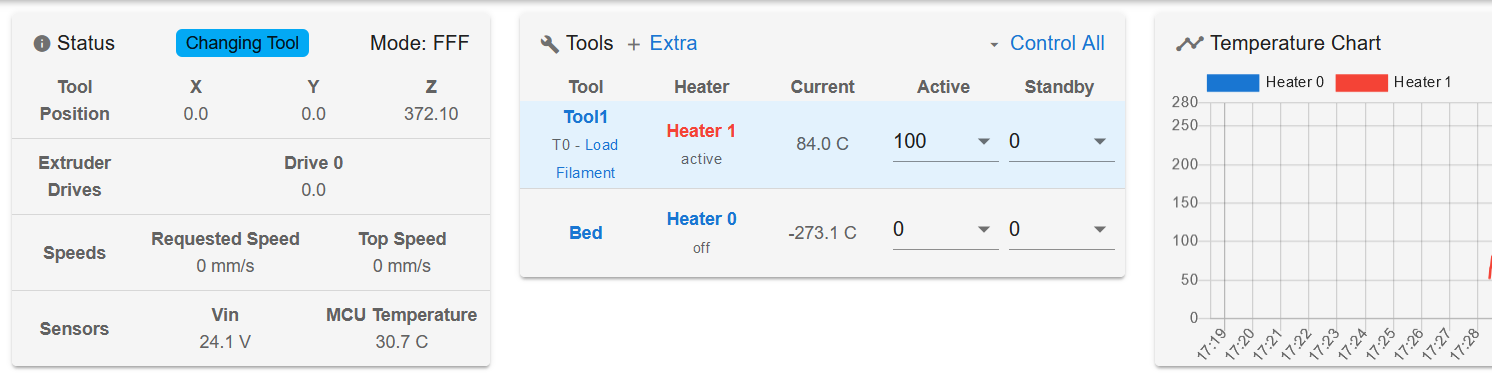

Available tools: 5 (for now)

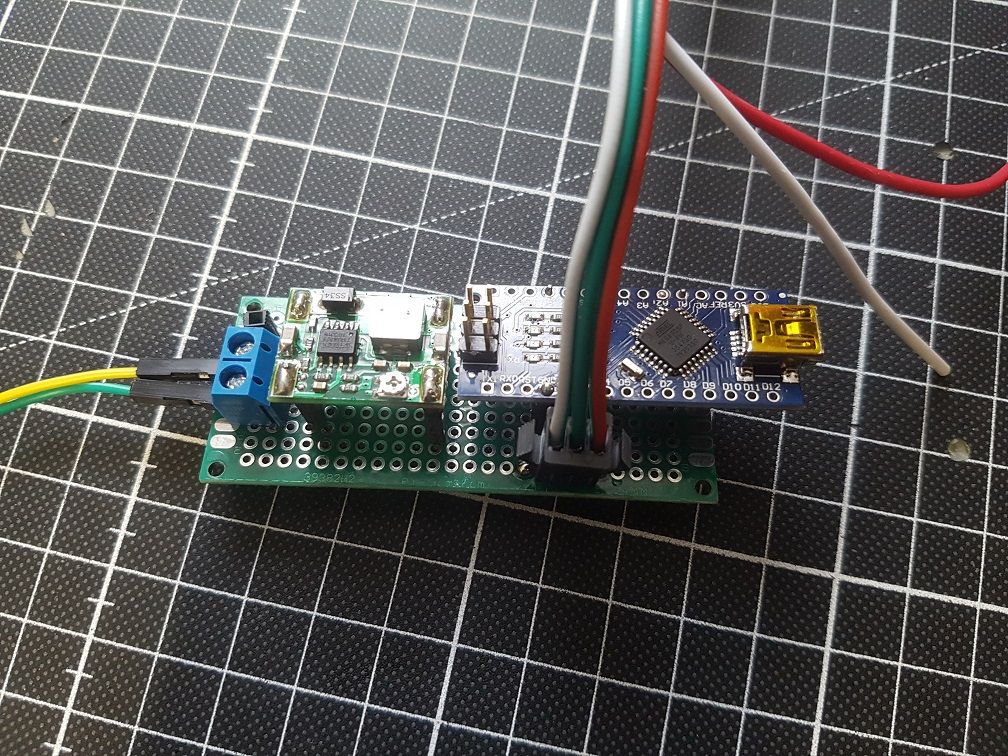

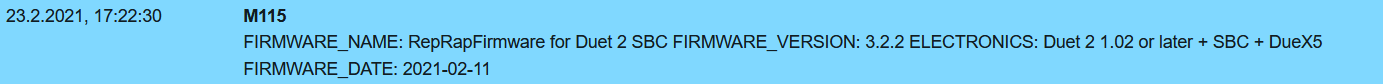

Board: Duet 2 Wifi + Duex 5

Power Supply: 24V 13A Meanwell

Security: Circuit breaker + RCD +Emergency Stop

Bed: milled aluminium bed with 600W mains heater switched with SSR

Print surface: Magnetic bed

Tool-Changing: Automatic and Manual

Control: PanelDue

I will updated the tread when I make more progress.

I'm really curious about your opinions and please let me know if you have any questions.