@T3P3Tony It's specifically the servo motor for the extruder that's causing the issue. With the servo driver turned off, there is zero issue.

I'm not convinced the cabling can be improved sufficiently. Looking at the graph for heater 3 and 4 (orange and grey) it's perfectly smooth now. These are running in 4 wire mode and have a deviation of just +-0.1°C.

The issue seems too specific to be random interference. It seems more like the servo signal is messing with the conversion chip within a specific temperature range causing a sort of avering of the value?

Latest posts made by pbulcke

-

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

-

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

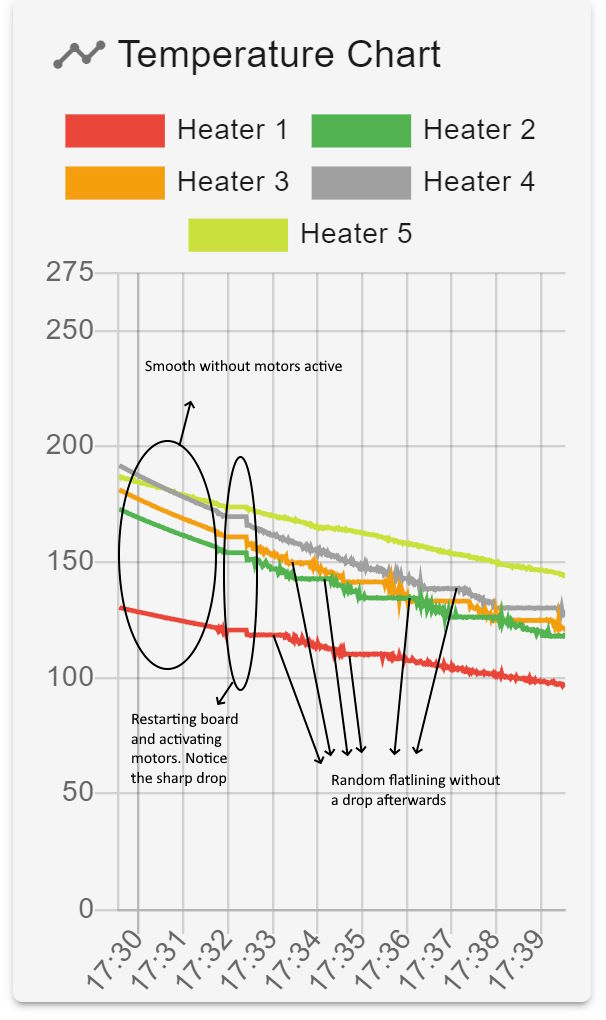

After double checking and adding additional ground points for the shielding of both the servo motor and temperature sensor cables, the noise on the signals has reduced significantly. Heater 4 (grey line) eg looks very smooth.

This clearer graph suddenly shows a very clear picture of the problem:

-

The flatlining happens between 120 and 150°C. This is a problem because heater 1 operates in this window.

-

The duration of a flatline is proportional to the heating/cooling rate. During normal printing with somewhat stable temperatures, this gives a worst case.

-

The flatlining only happens on the pt100 sensors.

This problems keeps getting weirder with no real solution in sight now... Not sure what to do next

-

-

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

@T3P3Tony I only posted a cooldown temperature graph but the issue is the same when heating up and printing! I have lost several prints now due to temperature instability causing flow rate issues.

I will take a look at the change notes for newer RRF versions.

Separaing the wires is not fully possible. They are together in the drag chaines which are several meters each.

Tomorrow I can try several possible solutions but this issue needs to be sorted soon. I use this printer professionally.

Thanks -

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

Below is the M122 report as requested.

Wiring:

In the meantime I checked the grounding of the cable shielding and added extra grounding points. This improved the overall noise but the flatlining issure is still there.

I was also able to determine that the servo drive for the extruder is causing the issue. The other stepper motors give no real interference.

Unplugging the signal cable from the duet to the servo drive made no difference.Next steps I can try are:

-swapping the pt100 daughterboards around and see if the issue remains in both. Perhaps the lower board is messing up the top board?

-installing an extra EMI filter on the power lines to the servo drive. I have an EMI filter on the general input to the printer.Is it correct that this issue is messing with the temperatures the PID's are using and thus causing the temperature fluctuations I'm having?

Have you seen this flatlining before?Thanks in advance. Pieter-Jan

-

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

@droftarts

As you mention, the first flatline is a drop in communication with a perfect flatline. The others still have a very slight signal on them it seems. The duration also differs. Looking at DWC on my phone at the same time as my computer shows the exact same on both.I agree it seems like voltage issue. But it does suprise me that the signal of 2 sensors on the same PT100 daughterboard differ.

All motors have external drivers. 2 are on a 48v psu, the others are 230V directly.

Here is the config file. This wasn't changed for 2 years.

config 22-10-10.gI believe the firmware is RRF 3.1.1, I can check in the next days. Then I can also get an M122 report.

This is probably a hardware issue then since it came on so suddenly?

Thanks, Pieter-Jan -

RE: Temperature flatlining temporarilyposted in Duet Hardware and wiring

@Phaedrux Thanks for the screenshot edit

The PT100's are 4 wire but I run them in 2 wire mode.

Even with better cables the interference caused a 2000C reading in 4 wire mode.

The normal interference (+-1°C) has never been a problem for stable operation. -

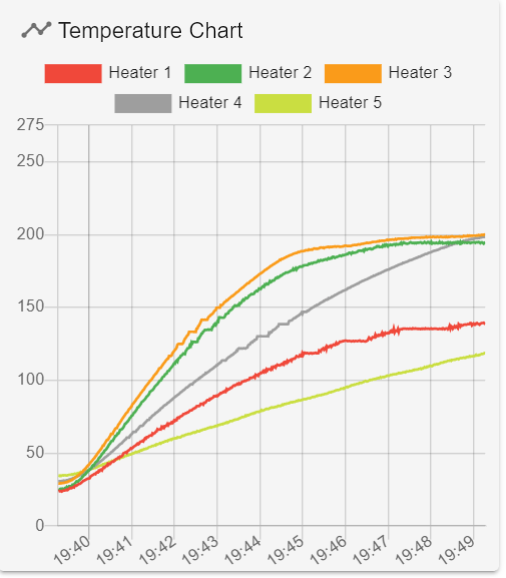

Temperature flatlining temporarilyposted in Duet Hardware and wiring

Hi I'm running a big screw extruder controllerd by a Duet 2 for 3 years now and recently the PID controller is misbehaving randomly. After spending way too much time attempting to retune the PID parameters, I noticed strange temperature behaviour.

Heaters 1-4 are PT100's on 2 daughterboards. Heater 5 is a thermistor connected directly to the duet. Heaters 1-4 randomly flat line for a about 1 minute.

On the attached image the behaviour is visible whilst cooling down. It only happens when the motors are active. These give some interference despite all the hardware precautions. The constant small jitter has always been there and was never a problem.

The temperature occasionally stays stable even though it is cooling down. The same happens when heating up. I believe this false temperature reading is feeding to the PID, messing it up.

The strangest part is this false temperature is then smoothly corrected for, it's not jumping directly to the true value.

How could this be explained and corrected? Thanks!