@oliof I am very sorry that it took me so long to respond to you, but I have not been able to access the printer until today.

As you requested, I will show you the configuration file.

Thank you very much for the help.

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Thu Nov 24 2022 23:03:50 GMT+0100 (hora estándar de Europa central)

; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Estanisleitor 2P" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X239.65 Y240.15 Z2402.00 E427.9:427.9 ; set steps per mm

M566 X900.00 Y900.00 Z400.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z400.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X200.00 Y200.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1700 Y1700 Z1700 E1100:1100 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-39 Y0 Z0 S1 ; set axis minima

M208 X462 Y378 Z419 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

:Z-Probe

M950 S0 C"exp.heater3"

M558 P9 C"^zprobe.in" H3 F300 T6000 ; FW v3 BLTouch connected to Z probe IN pin

G31 P500 X61.2 Y8.4 Z0.64 ; Set Z probe trigger value, offset and trigger height Incrementar el valor = acercar la mesa de impresión.

M557 X24:460 Y11:376 S60 ; Define mesh grid

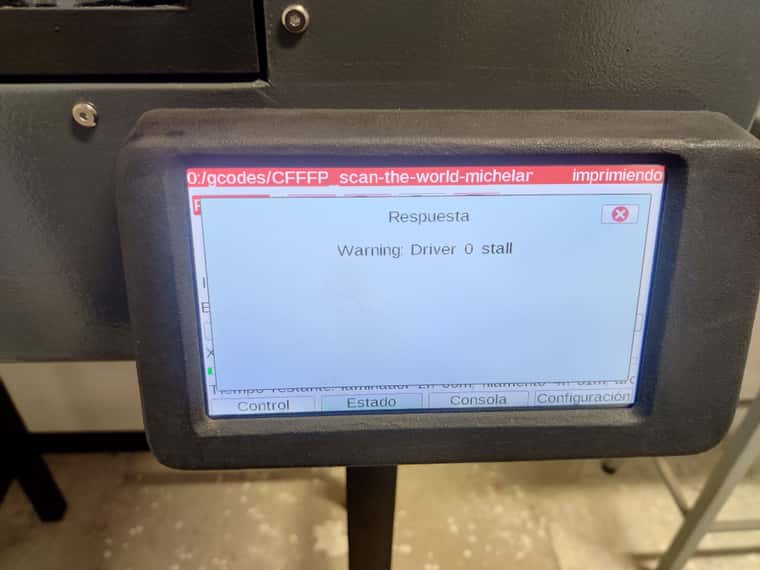

M915 X Y S5 R2

M950 H6 C"nil" ; Disable heaters H3-H7 to free up pins

; Heaters

M308 S0 P"e0temp" Y"pt1000" ; configure sensor 0 as PT1000 on pin e0temp

M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0

M570 H0 P400 T400

M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H0 S420 ; set temperature limit for heater 0 to 450C

M308 S1 P"e1temp" Y"pt1000" ; configure sensor 1 as PT1000 on pin e1temp

M950 H1 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1

M570 H1 P400 T400

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S420 ; set temperature limit for heater 1 to 450C

M308 S2 P"bedtemp" Y"pt1000" R4700 ; configure sensor 2 as PT1000 on pin bedtemp

M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2

M307 H2 B0 S1.00; disable bang-bang mode for the bed heater and set PWM limit

M570 H2 P1200 T90 ; comando añadido porque tarda mucho en calentar la cama y daba error

M140 H2 ; map heated bed to heater 2

M143 H2 S130 ; set temperature limit for heater 2 to 180C

Cámara

M308 S3 P"e3temp" Y"pt1000" R4700 ; configure sensor 3 as PT1000 on pin duex.e2temp

M950 H4 C"exp.heater4" T3 ; create chamber heater output on duex.e3heat and map it to sensor 3

M307 H4 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M570 H4 P4200 T110

M141 H4 ; map chamber to heater 3

M143 H4 S70 ; set temperature limit for heater 3 to 90C

Ventiladores

Ventilador de pieza

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Ventilador De Pieza" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

Bomba de agua y ventilador radiador

M308 S4 P"e4temp" Y"pt1000" R4700 ; configure sensor 4 as PT1000 on pin duex.e5temp

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"Ventilador De Cabezal" T60 H4 X1 ; set fan 1 name and value. Thermostatic control is turned on

Ventilador Filtro Cámara

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"Ventilador De Cámara" T60 H3 X1 ; set fan 2 name and value. Thermostatic control is turned on

Ventilador Cabezal soplador

M308 S5 P"e5temp" Y"pt1000" R4700 ; configure sensor 5 as PT1000 on pin duex.e6temp

M308 S6 P"e6temp" Y"pt1000" R4700 ; configure sensor 6 as PT1000 on pin duex.e7temp

M950 F3 C"exp.heater7" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P3 C"Soplador Cabezal" T40 H5:6 X1 ; set fan 1 name and value. Thermostatic control is turned on

Bomba Aire MotorY

M308 S7 P"e2temp" Y"pt1000" R4700 ; configure sensor 6 as PT1000 on pin duex.e7temp

M950 F4 C"exp.heater5" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P4 C"Bomba Aire MotorY" T50 H7 X1 ; set fan 1 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"Material Base" D0 H0 F1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Soporte" D1 H1 F1 ; define tool 1

G10 P1 X38 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

M591 D0 P2 C"e0stop" S1 ; Final de Filamento extrusor 0

M591 D0 P2 C"e1stop" S1 ; Final de Filamento extrusor 1

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined