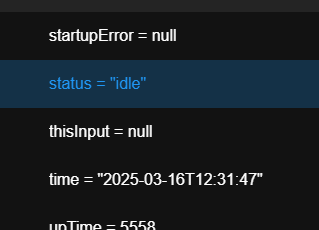

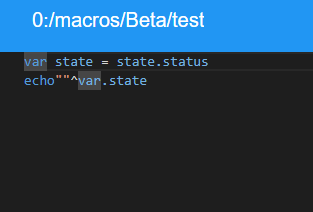

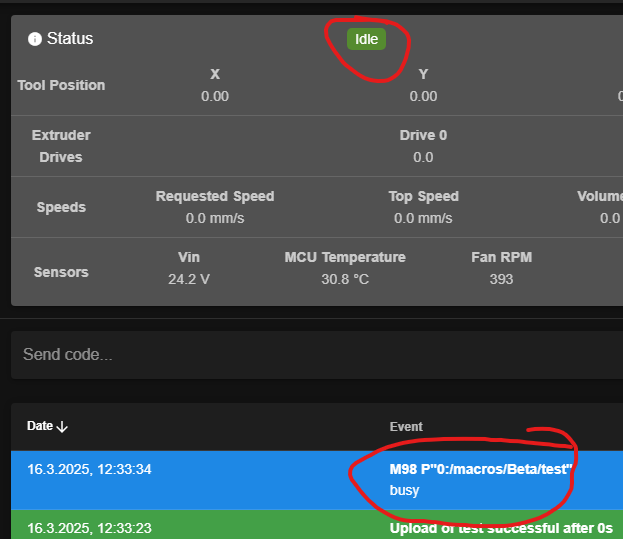

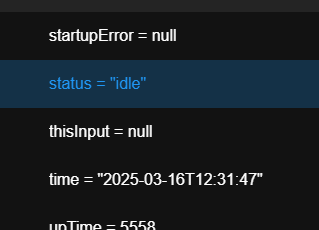

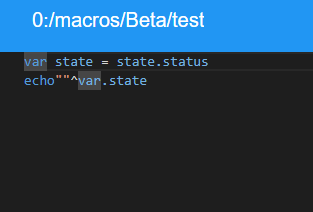

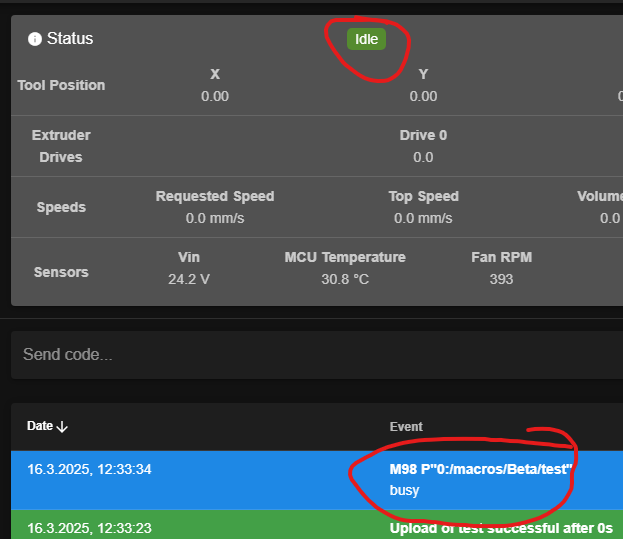

In dwc, state.status is displayed as idle as well as in the object model. However, busy is displayed when I query state.status via meta commands.

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-rc.1 (2025-02-28 14:59:42) running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: 9458S-K296U-D65J0-40KMW-LM03Z-R6DMH

Used output buffers: 1 of 40 (29 max)

=== RTOS ===

Static ram: 94764

Dynamic ram: 95596 of which 392 recycled

Never used RAM 50716, free system stack 188 words

Tasks: NETWORK(1,nWait 7,16.2%,173) HEAT(3,nWait 6,0.0%,350) Move(4,nWait 6,0.0%,353) TMC(4,nWait 6,0.8%,99) CanReceiv(6,nWait 1,0.1%,771) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,348) MAIN(1,running,82.0%,402) IDLE(0,ready,0.1%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,261), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 01:37:25 ago, cause: power up

Last software reset at 2025-03-14 07:38, reason: User, Gcodes spinning, available RAM 49956, slot 1

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00489000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

=== Storage ===

Free file entries: 20

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 6.7ms, write time 92.6ms, max retries 0

=== Move ===

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00

No step interrupt scheduled

Driver 0: standstill, SG min 0, r/w errs 0/0, ifcnt 14, reads/writes 45469/14, timeouts 0, DMA errs 0, CC errs 0

Driver 1: standstill, SG min 0, r/w errs 0/0, ifcnt 10, reads/writes 45473/10, timeouts 0, DMA errs 0, CC errs 0

Driver 2: standstill, SG min 0, r/w errs 0/0, ifcnt 10, reads/writes 45472/10, timeouts 0, DMA errs 0, CC errs 0

Driver 3: standstill, SG min 0, r/w errs 0/0, ifcnt 10, reads/writes 45472/10, timeouts 0, DMA errs 0, CC errs 0

Driver 4: standstill, SG min 0, r/w errs 0/0, ifcnt 10, reads/writes 45473/10, timeouts 0, DMA errs 0, CC errs 0

Driver 5: not present

Driver 6: not present

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== CAN ===

Messages queued 51122, received 303963, lost 0, ignored 0, errs 619, boc 0

Longest wait 2ms for reply type 6062, peak Tx sync delay 959, free buffers 26 (min 25), ts 27703/27702/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 205.88ms; fastest: 0.00ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.2.1

Module reset reason: Power up, Vcc 3.40, flash size 2097152, free heap 39188

MAC address f0:08:d1:03:80:57

IP address 192.168.178.65

Signal strength -45dBm, channel 6, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0