since it has just affected me I would make a warning that if the SSD relay fails and short circuits then the heated bed supply is switched on 100% and not controllable by the Duet. Yesterday my SSD failed and I found the 300mm diameter hotbed heated by my 240v supply to "240 degrees" (maybe it was more than that depending on the thermistor accuracy ). The Duet recognised it as a heating error (temp on the PanelDue was in purple) and no voltage was present on the SSD input. A new SSD fixed the problem, but I am going to put a further safety switch off system into place. Am researching this so looking at either a separate independent system apart from the Duet that will cutoff the 240v supply over a certain temperature, a relay controlled by the Duet to switch the heatbed 240v off when the Duet senses the heatbed error, a thermal fuse on the 240v line next to the heatbed that blows on high temperatures…...

Not sure how to switch the relay from the Duet which would be fairly simple. ..?via the 5v PSU control.

Best posts made by Paulh

-

RE: Controlling my heated bed and SSR from DuetWifiposted in Duet Hardware and wiring

Latest posts made by Paulh

-

RE: New Smart effector vs4 problemsposted in Smart effector for delta printers

@Phaedrux

thanks for the replyI am grateful for any suggestion and also from o_lampe.

i am away in the countryside for the weekend but will check again re the operating system but am pretty sure am running 2.03. I have looked at RRF3.4 and will probably upgrade but know changes to the gcodes need to be done too with this. I have not needed to upgrade with the previous effector version 2.My connundrum is that there is also a clear misfit of the heatsink and the effector: the fit is too tight and the effector may be tilted as a result of this, even after tightening (it was very difficult to remove when I diassembled it all). Reaming the hole in the effector would help but I don't want to do this in a new device.

Hence I have at least one hardware issue, maybe more. The hard probing could be from software too... or other.

Since I have a work around already, using a previous version 1 smart effector modified to work with an IR probe, the printer is working so I am not desperate, just disappointed.I have replied to E3d too about this.

I will change to RRF 3.4 soon. -

RE: New Smart effector vs4 problemsposted in Smart effector for delta printers

I submitted this post as requested by E3d for potential return of the effector since it is faulty (this may have been less clear due to the other issue also discussed) .

-

RE: Faulty smart effectors (yes, plural)posted in Smart effector for delta printers

@Phaedrux

I had similar issues with the version 1 , 2 and now version 4 effector the last being straight out of the box : still no reply to my very recent enquiry in the smart effector forum although many reads. I have the same issue as janjoh that after 2-3 years my 2 other effectors (versions 1 and 2) failed as evidenced by the "horrid noise of belt grinding" and the bed being hit very hard on probing. The experience with the new version 4 was not better.

My usage would not be deemed very great although maybe slightly more than janjoh. -

New Smart effector vs4 problemsposted in Smart effector for delta printers

I have been using smart effectors for many years : have had the version 1 and version 2 that worked well. I did have print fan noise affecting the version 2 but did most of the probing with it off. Unfortunately the previous effectors after a good life failed : the vs 1 from PCB track damage and the vs 2 recently due to voltage spike that wiped out the Duet 2 , PT100 daughterboard and the Effector probing. Fortunately I had a standby Duet2 WIFI and PT100 board that were known to work well.

Hence I bought a vs4 smart effector and a new heatsink, cooling fan, heater, hotend block and new PT100 from E3d. I carefully put it together , tightened the hotend onto the effector, tested that it was triggering by tapping the hotend and tried probing.

The result was the effector probing the bed hard when it was slowly lowered onto the bed, and this happened not just at the 1st probe but through the whole cycle and when repeated the hotend tried sometimes to probe off the bed indicating the belt had slipped as a result of the initial probing.The effector indicator LED is blinking correctly (3 on startup due to changed sensitivity), can be reset M672 S131:131 and 5 blinks appropriately then, and does not indicate any errors eg multiple 6 blinks etc, it blinks on tapping the hotend so seems to work OK.

I tried altering the sensitivity down low to 10 which just falsely triggered even when lowering to the bed and then to 20 and 30 that managed to probe except still having hard strikes, although some appeared to probe softly (which was the aim). Higher setting levels also tried which were worse.

Probe readings from bed.g did not get anywhere near the previous 0.04 or so level that had been previously obtained with the setup. At best .35 was obtained which worsened on reprobing. Often there was nil result due to false triggering before the bed was reached (this happened at all sensitivities of probing). After a few tries with fans on I removed these and the results described here are from a fanless effector.After all this I decided to pull the effector apart : the heatsink was very very firmly attached to the effector after tightening it indicating the clearance was very tight.

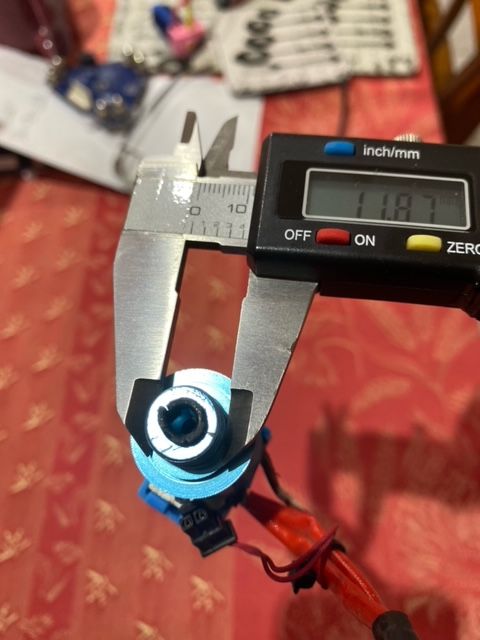

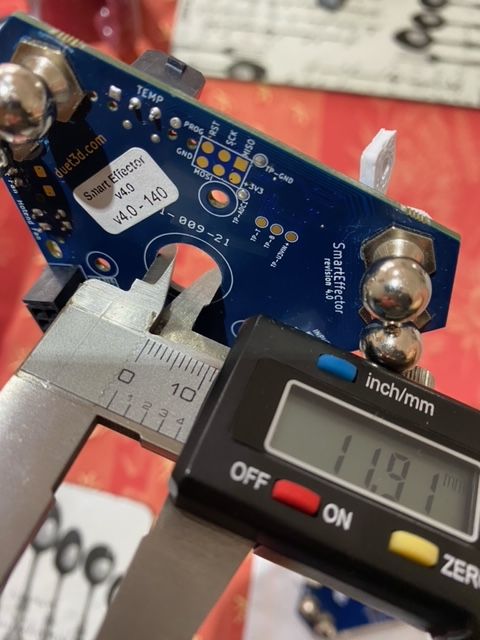

Measurement of the hole vs the heatsink confirmed the tight fit . I compared to my older vs2 effector.

New effector hole 11.93mm diameter , old 12.08mm:

New heatsink width 11.92 diameter , old 11.85mm, clearance better but not wobbly so good fit .

Note these are averages of 4 measurements, and seen as a comparison of diameters rather than very exact measurements.

I am enclosing with this sample measurement photos.The old heatsink does fit the new vs 4 effector firmly and does not have to be forced in like the new one. Obviously the clearance is less tight than the new heatsink on the new effector (expected from the measurements)

I have tried the old heatsink with block etc on the new effector and tightened it well but the effector, with sensitivity setting of 20, is still probing the bed hard but not on every probe point (some are softly probing the base). Hence the probing issue remains the same despite the hope that the poor fit of the heatsink on the effector was the problem.Setup: Duet 2 WIFI running Firmware 2.03, running on DC42 like Delta printer with wide base (allowing 400mm + diameter bed), Hayden Huntley magnetic arms but printing standardly on 300mm bed. The bed being probed is very stable and firmly placed: aluminium supports attached to the delta supports holding 2 x 3mm depth aluminium round plates and on top is a 300mm diameter 5 mm thick glass plate. 10 points of probing was standard. Bed heater and its insulator were removed for the tests with changes in the height setting to account for this since the soft heater and supports have been shown by me to sometimes affect the probing in my experience.

M558 P8 R0.4 F120 ; for smart effector to initial setup . Slow speed probing as used previously. This has been standard for my probing in past.

G31 P100 X0 Y0 Z-0.1 ; for setup initiallyM350 X16 Y16 Z16 E16 I0; microstepping

In summary the effector bought on initial set up appeared initially to be Ok , and sometimes gently probes the bed as it should but unfortunately more often than not heavily probes the bed (the movement of the bed can be seen and the effector seems to distort too), even on different settings. It is unreliable and poor results are obtained even when probing seems to work. The poor fitting of the heatsink to the effector is of concern but is probably not the cause of the probing problems (it may be adding to them though).

Thinking back to years ago the issues are similar to my version 1 when the PCB traces were probably damaged and probing became unreliable. My version 2 has worked well and reliably until being wiped out by the voltage spike recently. Hence my settings seemed Ok.

In my opinion a replacement of the effector is probably needed. The poor fitting of the heatsink with the effector needs to be addressed also.

Many thanks

Paul

E3d have been told about this too: my recent note to them is below.

Notes to E3d re photos:

here are some images of the caliper measuring the heatsinks and effector as requested: an old one bought through Duet3d with version 2 smart effector from March 2020 and the recent one from you with version 3 smart effector. As far as I am aware the old heatsink was made by E3d too or at least designed by E3d. The new heatsink is more blue in colour.The pointy part of the calipers is measuring the base of the "thread" that inserts into the PCB on the smart effector and the thicker part of the caliper is measuring the thread itself width that the nut screws onto.

In fact the heatsink difference of the part inserted into the PCB is only very marginally larger than the 2020 one. However even your recent heatsink is a very firm fit into the version 2 smart effector in comparison to the older 2020 heatsink indicating that even the slight increase increase in size is noticeable in the fit to the older smart effector too.

The obvious big difference in measurement is the smart effector hole width which is of the order 0.1mm different between the 2 effectors according to me.. In addition the heatsink threads seem very similar width but the actual thread itself is a different screw type than the 2020 version. Hence the nuts are not interchangeable which really is not an issue.

I suggest in addition you try your heatsinks in stock with the smart effector in stock to see if you have the same issues as I have since it will be an ongoing issue for anyone buying the same things eg a heatsink with the smart effector.

-

RE: Controlling my heated bed and SSR from DuetWifiposted in Duet Hardware and wiring

SSD that failed was bought from ebay:

Solid State Relay Module SSR-25DA 25A /250V 3-32V DC Input 24-380VAC Output GT

"futek" brand

( 182110092170 goodgadgetsa )

Planning to put Thermal cutout under the heatbed, in series with the 240V supply to the bed.

The cork insulation worked well and worthwhile. Limiting the maximal temperature by choosing appropriate heater wattage sounds wise to me but is only known after it is fitted. -

RE: Controlling my heated bed and SSR from DuetWifiposted in Duet Hardware and wiring

since it has just affected me I would make a warning that if the SSD relay fails and short circuits then the heated bed supply is switched on 100% and not controllable by the Duet. Yesterday my SSD failed and I found the 300mm diameter hotbed heated by my 240v supply to "240 degrees" (maybe it was more than that depending on the thermistor accuracy ). The Duet recognised it as a heating error (temp on the PanelDue was in purple) and no voltage was present on the SSD input. A new SSD fixed the problem, but I am going to put a further safety switch off system into place. Am researching this so looking at either a separate independent system apart from the Duet that will cutoff the 240v supply over a certain temperature, a relay controlled by the Duet to switch the heatbed 240v off when the Duet senses the heatbed error, a thermal fuse on the 240v line next to the heatbed that blows on high temperatures…...

Not sure how to switch the relay from the Duet which would be fairly simple. ..?via the 5v PSU control.