So, sorry for hijacking the sticky Guide thread. I hope that someone can guide me to solve this dilemma

I'm having a strange issue with the Pressure Advance feature, and reading most of the topics here on the forum and trying different values, I am still at a lost and don't know exactly how should I proceed.

My setup is as follows:

Duet Wifi 2 controller, Firmware 2.05.1

Bowden around 250mm in lenght, E3D V6, with simple extruder, no gear reduction.

Printing in ABS, 230°C

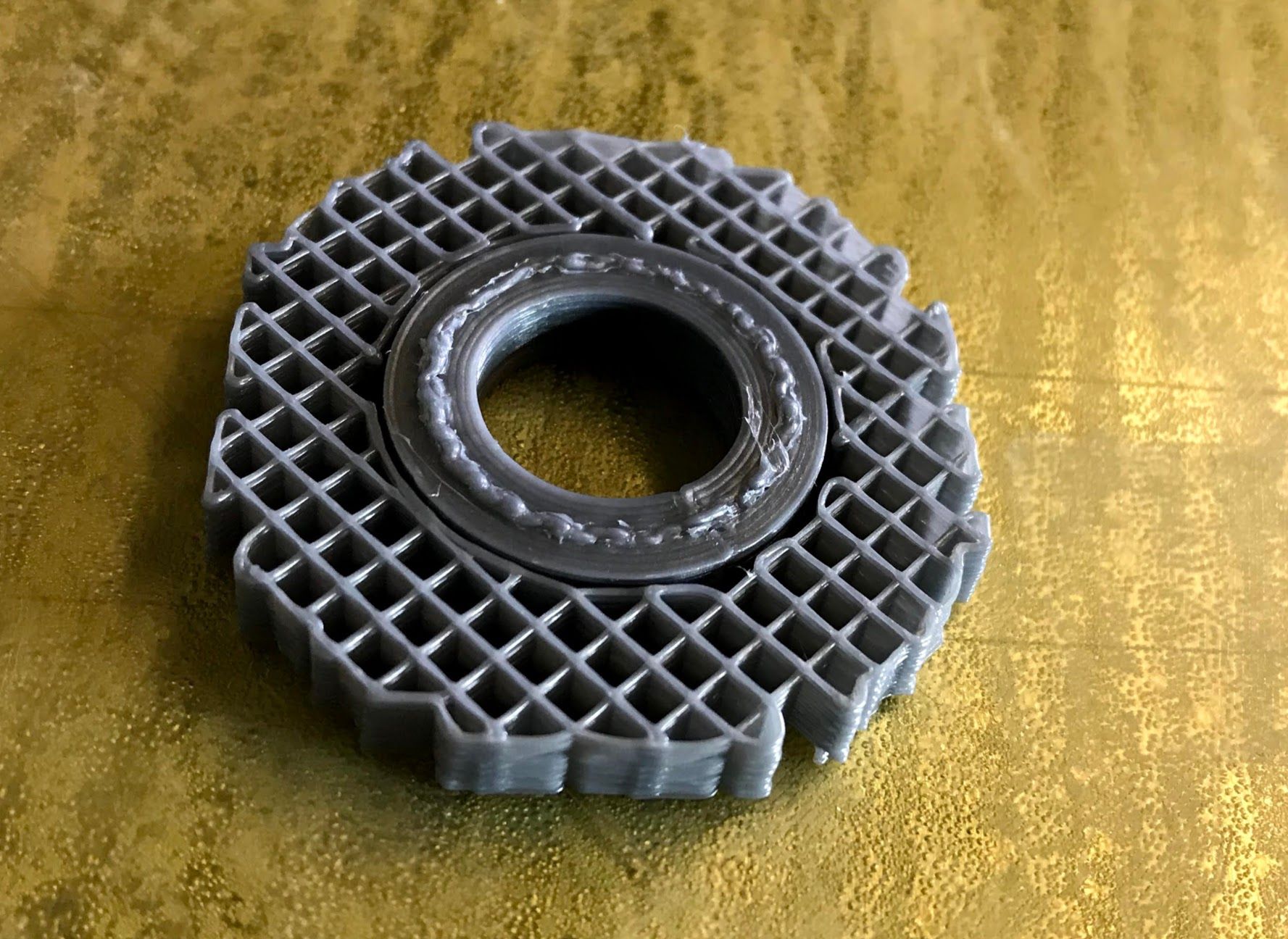

I found my "ideal" pressure advance value to be around 0.35 - 0.4 with sharp corners and start and end lines that are quite consistent in width. In most of my parts, let's say 98% of them, I can find no fault. The rest however, whenever I have a very short travel zig-zag infill, like in the tests presented in the guide thread, I get a huge blob of filament, like I would have the extrusion bumped up to 200%. No matter what value I set, everything above 0.05 will give me this effect, even going up to 0.9 or 1.0 . It will stop and print a normal infill if I disable Pressure Advance completely or the value is extremely low, under 0.05 which will effectively disable it for my setup.

There was another similar topic here and the explanation was that during these short zig-zag moves, the filament does not have the time to compress and decompress in the bowden tube, so for such short moves, the pressure advance should be disabled. I am not sure if anybody found a solution though..

What am I doing wrong here ?

Thanks for the help.