I mean in the config.g file but as I mentioned I don't think this is a solution!

As T3P3Tony said there could be a tool change in the actual gcode.

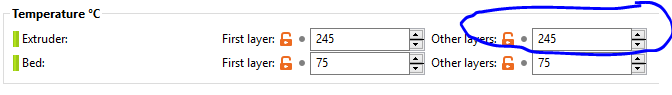

Another problem could be that your customer set the temperatur for the first layer right but changed the temperatur of the other layers. I know this from the prusa slicer:

But then it doesn't make sense that the tool gets deaktivated...