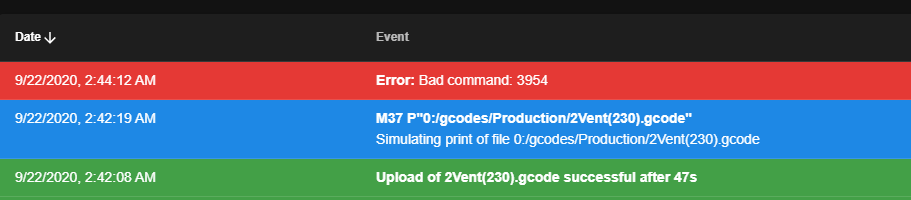

Alright, I'm at my wits end. Is there a bug with pressure advance?

Board: Duet Maestro 1.0 (duetmaestro100)

Firmware: RepRapFirmware for Duet 2 Maestro 2.05.1 (2020-02-09b1)

Yes old firmware, just haven't felt like learning new firmware mid-build and it does everything I need.

Anyway, here's the problem:

Tuned e-steps, no problem. Tuned flow % in slicer, no problem (94.3%). Decided to tune pressure advance, did that (~300mm Bowden, landed on S0.4 for the PETG I usually print).

So then I do a quick print, and it fails. Nozzle caught the print, shifted the bed. Don't think twice about it, made sure I had z-hop, slowed it down, reprinted. Print finishes, but it's pretty ugly. Top surfaces clearly show overextrusion, and (it's the tolerance test piece from the Cura plugin) all the cylinders are welded into the part.

I had already printed this before tuning pressure advance, everything was free except the 0.2 (aka, 0.1mm wall to wall clearance)).

Odd.

Checked slicer settings, all fine.

Decided to print my flow % tuning model (Made a piece where the perimeter length = 1 full rotation of filament drive gear).

With no pressure advance, the walls come out 0.39-0.42. With pressure advance they come out 0.42-0.45.

So ~7.5% overextrusion. Very odd, but also didn't really match the tolerance piece over-extrusion. It was visually worse, and the dimensions of the part went from 60x12 (+/-0.05) to 60.3x12.3.

I re-sliced the part to have only bottom surfaces and 3 walls. Printed with no pressure advance, 1.2mm walls. Printed with pressure advance, 1.5mm walls!! And that matches the 0.3mm the model grew.

Just to validate, I re-sliced with flow at 72%. No pressure advance, the part barely stays together it's so under-extruded. With pressure advance, the model prints perfect. The cylinders are less oval by a couple dozen micron, everything is dimensionally accurate, and even the 0.2 is free.

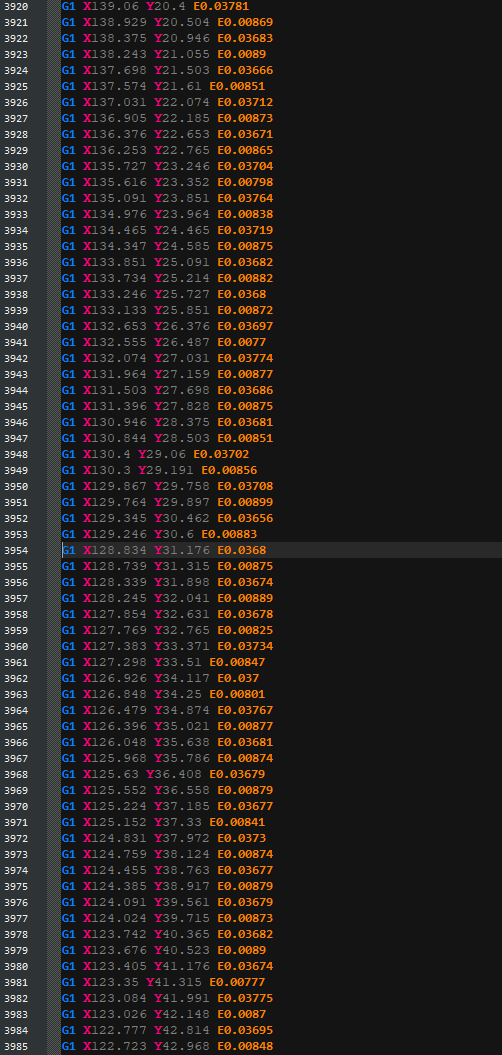

So the only thing that comes to mind is the pressure advance implementation has a massive bug. And it wouldn't be that bad if it was consistent. But since the overextrusion is varying between ~7% and ~25%, I have no option but to keep it off.

Anyone ever seen this behavior or have any thoughts (besides fiddling with firmware versions)?