5 differnt windows pc all confirmed ports working and used same cable to program other devices . no issues but this on cant get a port , going try a linux and mac next

device manager no chime or anything in device manager will try powered hub next

Best posts made by morf33

-

RE: duet 2 wifi , erased no port after erase .posted in Firmware installation

Latest posts made by morf33

-

cura building a speed testposted in General Discussion

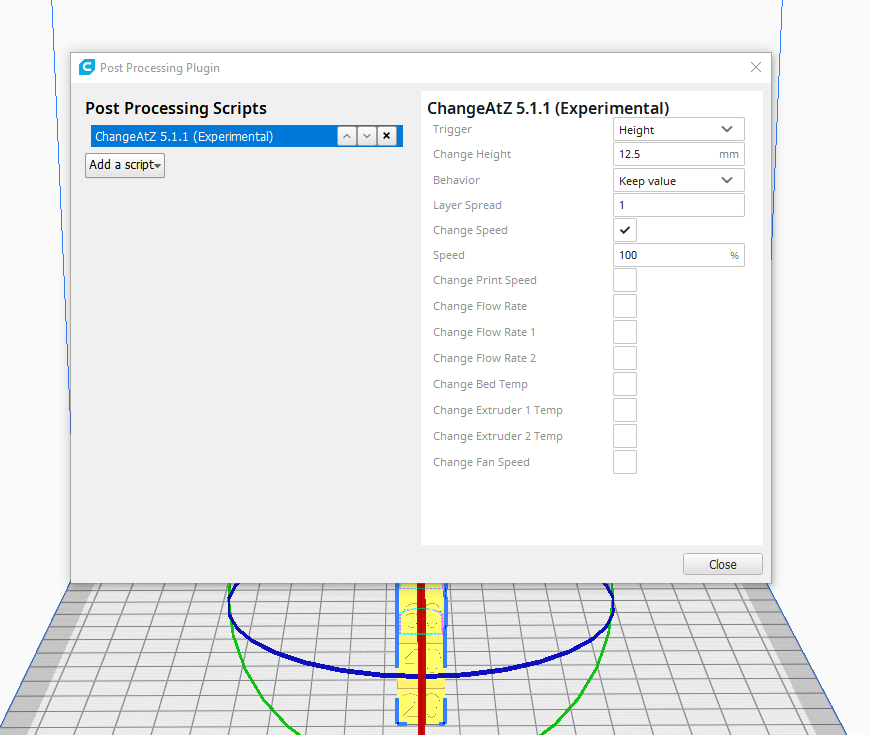

ok i am really new to 3d printing and i searched a lot for building a speed test

i been using cura , and i found plenty of speed test on a site but i wanted to put a brim on the speed test now i am trying to build the speed test in cura but i know to go to processing post script but i am not sure what to put for speed to chance every 12.5

do i start at speed 100% ad then click change print speed or speed ? what should i put for it to change speed every 12.5 mm

-

RE: mesh bed leveling issueposted in Tuning and tweaking

oki set it to 170 becasue it would try to keep going but i now find out that the y is moving more than it should

10mm is 13mm when it moves so i need to adjust the steps ? -

an8 blv mod duet 2 wifi calibrationposted in General Discussion

good day ok i got a question . i got my duet working bl touch and all i printed a 20mm x 20mm test cube .

sliced in cura . cura shows its right 20 x 20 mm . i do a print and my x and z are good but my y is 25mm

i verified all my motors are the same model and type . so i am 20mm x 25mm x 20mm cube . here is my config file .

should i just change my y steps or should i do something else ?

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E409.00 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X500 Y500 Z500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-10 Y0 Z0 S1 ; set axis minima

M208 X220 Y190 Z240 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-low endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-low endstop for low end on Y via pin ystop

;M574 Z1 S1 P"!zstop" ; configure active-low endstop for low end on Z via pin zstop

M574 Z0 ; configure Z-probe endstop on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T2000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-42 Y-40 Z1.067 ; set Z probe trigger value, offset and trigger height

M557 X15:220 Y15:190 S50 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool

M501

-

RE: mesh bed leveling issueposted in Tuning and tweaking

this is in the bed g file

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time)

M561 ; clear any bed transform

G29 ; probe the bed and enable compensation -

RE: mesh bed leveling issueposted in Tuning and tweaking

were would that info be what files do i need to post ?its the drop down menu for the mesh compensation.

-

RE: mesh bed leveling issueposted in Tuning and tweaking

when you do autohome when it goes thru to do the endstops it will center on the center of the bed after it does the z probe of the bed . when i click mesh it starts in the middle of the bed . how do i get it to start at the corner like it should

-

mesh bed leveling issueposted in Tuning and tweaking

ok i am trying to get the run mesh compensation my printer is 220 x 220 and i have it were it homes in the middle .

when i press the mesh compensation it starts in the middle of the bed and not the top left . what do i need to do to get it to move to the top left for mesh compensation ? no files on my sys for mesh .

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E409.00 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X500 Y500 Z500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-13 Y-3 Z0 S1 ; set axis minima

M208 X200 Y170 Z240 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-low endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-low endstop for low end on Y via pin ystop

;M574 Z1 S1 P"!zstop" ; configure active-low endstop for low end on Z via pin zstop

M574 Z0 ; configure Z-probe endstop on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T2000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y-40 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X55:200 Y55:170 S60 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool_________________________________________________________________________________________________________________________; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-258 Y-235 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-258 Y-235 F360 ; move slowly to X and Y axis endstops once more (second pass)

;G1 H1 Z-245 F360 ; move Z down stopping at the endstop

G90 ; absolute positioning

;G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

G1 X114 Y83 F4000 ; Move probe to middle of bed

G30

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

-

RE: Bl touch issues not homing z with bl touch .posted in Firmware installation

all is good now , thank you all for the assistance

-

RE: Bl touch issues not homing z with bl touch .posted in Firmware installation

now the z wont go down and then the bltouch proble extends then it retracts after a min and gives this error .

G28

Error: Z probe was not triggered during probing move -

RE: Bl touch issues not homing z with bl touch .posted in Firmware installation

wow ok this is back to yesterdays issue . bl touch works now but when homing z , x and y do fine and z goes all the way to the right . upgraded the firmware see below for homeall ,config and firmware version

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-258 Y-235 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-258 Y-235 F360 ; move slowly to X and Y axis endstops once more (second pass)

;G1 H1 Z-245 F360 ; move Z down stopping at the endstop

G90 ; absolute positioning

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

G1 X15.5 Y35 F4000 ; Move probe to middle of bed

G30

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Jul 23 2020 14:47:56 GMT+0300 (Arabian Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E100.00 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X500 Y500 Z500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-33 Y-10 Z0 S1 ; set axis minima

M208 X220 Y220 Z240 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-low endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-low endstop for low end on Y via pin ystop

;M574 Z1 S1 P"!zstop" ; configure active-low endstop for low end on Z via pin zstop

M574 Z0 ; configure Z-probe endstop on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T2000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y-40 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X55:200 Y55:200 S60 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-05-19b2