I have a toolboard configured as board 2 with three endstops in series, X, Y & Z. I have the Z probe set to use the same endstop. The z-probe can be seen to trigger in DWC when a switch is pressed.

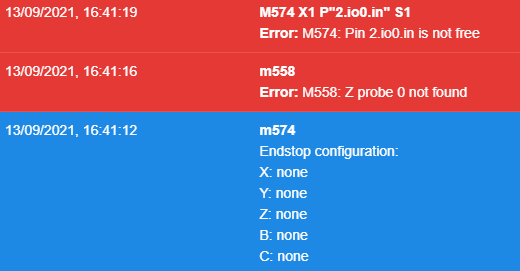

However, when issuing M574 X1 P"2.io0.in" S1 i get an error telling me the pin isn't free.

Error: M574: Pin 2.io0.in is not free

This happens even when the z-probe is not setup with M558 P8 C"2.io0.in" H3 F360 I0 T20000

I have been unable to find out why. I have a similar setup using X & Y endstops on a single toolboard, and that seems to run just fine on a different machine.

What am I doing wrong?

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Vogue" ; set printer name

M667 S1 ; Set CoreXY

; Drives

M569 P0.0 S0 ; X

M569 P0.1 S0 ; Y

M569 P0.2 S0 ; T1

M569 P0.3 S0 ; B

M569 P0.4 S0 ; T0

M569 P0.5 S1 ; Z

M569 P1.0 S1 ; T3

M569 P1.1 S0 ; T2

M569 P1.2 S0 ;

M569 P2.0 S0 ; C

M584 X0.0 Y0.1 Z0.5 E0.4:0.2:1.1:1.0 B0.3 C2.0 ; Drive mapping

M350 E16:16:16 C16 I0 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 B16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z800 B1600 C91.022 E396:396:396:396 ; Set steps per mm

M566 X100 Y100 Z50 C2 B200 E10:10:10:10 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z4000 B3500 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z125 B500 C500 E1000:1000:1000:1000 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 B750 I30 ; Idle motion motors to 30%

M906 E1330:1330:1330 C500 I10 ; Idle extruder motors to 10%

; Axis Limits

M208 X0:350 Y0:300 Z0:300 B0:50 C0:360 S0 ; Set axis maxima & minima

; Endstops

M574 B1 C1 S3 ; Set B C endstops to stall detection

M574 X0 P"nil"

M574 Y0 P"nil"

M574 Z0 P"nil"

; Setup Z-Probe

M558 P8 C"2.io0.in" H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X10:290 Y20:180 S40 ; Define mesh grid

; Heaters

M308 S0 A"Bed" P"temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out3" T0 ; create bed heater output on out2 and map it to sensor 0

M143 H0 S250 ; set temperature limit for heater 0 to 250C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 A"T0" ; define E0 temperature sensor

M950 H1 C"out1" T1 ; Extruder 0 heater

M143 H1 S305 ; Set temperature limit for heater 1 to 300C

M308 S2 P"1.temp1" Y"thermistor" T100000 B4725 C7.06e-8 A"T1" ; define E1 temperature sensor

M950 H2 C"1.out1" T2 ; Extruder 1 heater

M143 H2 S305 ; Set temperature limit for heater 2 to 300C

M308 S3 P"1.temp0" Y"thermistor" T100000 B4725 C7.06e-8 A"T2" ; define E2 temperature sensor

M950 H3 C"1.out2" T3 ; Extruder 2 heater

M143 H3 S305 ; Set temperature limit for heater 3 to 300C

M308 S4 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 A"T3" ; define E3 temperature sensor

M950 H4 C"out2" T4 ; Extruder 4 heater

M143 H4 S305 ; Set temperature limit for heater 4 to 300C

; Fans

M950 F0 C"out7" ; T0 Hotend Fan

M950 F1 C"1.out7" ; T1 Hotend Fan

M950 F2 C"out8" ; T3 Hotend Fan

M950 F3 C"1.out8" ; T4 Hotend Fan

M950 F4 C"out4" ; T0 Part Cooling Fan

M950 F5 C"1.out4" ; T1 Part Cooling Fan

M950 F6 C"out5" ; T3 Part Cooling Fan

M950 F7 C"1.out5" ; T4 Part Cooling Fan

M106 P0 T65 S255 H1 ; T0 HotEnd Fan

M106 P1 T65 S255 H2 ; T2 HotEnd Fan

M106 P2 T65 S255 H3 ; T3 HotEnd Fan

M106 P3 T65 S255 H4 ; T4 HotEnd Fan

M106 P4 S0 ; T0 Part Cooling Fan

M106 P5 S0 ; T1 Part Cooling Fan

M106 P6 S0 ; T2 Part Cooling Fan

M106 P7 S0 ; T3 Part Cooling Fan

; Tools

M563 P0 S"T0" D0 H1 F0 F4 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C

M563 P1 S"T1" D1 H2 F1 F5 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0C

M563 P2 S"T2" D2 H3 F2 F6 ; Define tool 2

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0C

M563 P3 S"T3" D3 H4 F3 F7 ; Define tool 3

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C

;Set Hotends to Standby

T0 P0

T1 P0

T2 P0

T3 P0

T-1 P0

; Machine settings

M501 ; Load config-overide.g

M575 P1 S1 B57600 ; Enable LCD

; homex.g

; called to home the x axis

;Set Endstops

M574 Y0 P"nil"

M574 Z0 P"nil"

M574 X1 P"2.io0.in" S1

T-1 ; deselect tool

G91 ; Relative mode

G1 H2 Z5 F5000 ; Lower the bed

G4 P50 ; wait 50msec

G1 H1 X-350 F5000 ; Move X until the switch triggers (first pass)

G4 P250 ; wait 250msec

G1 X5 F5000 ; go back a few mm

G4 P250 ; wait 250msec

G1 H1 X-10 F300 ; Move X until the switch triggers (second pass)

G1 X1 F5000 ; go back a few mm

G90 ; Back to absolute positioning

;Release Endstops

M574 X0 P"nil"

M574 Y0 P"nil"

M574 Z0 P"nil"