@deckingman Oh, and regarding cooling... I'm currently using a 120mm PC fan... but about to upgrade that to compressed air instead

Latest posts made by GHJENG

-

RE: Using 3HC for a Multi-Heater, Multi-Motor Extruder :) ???posted in Duet Hardware and wiring

-

RE: Using 3HC for a Multi-Heater, Multi-Motor Extruder :) ???posted in Duet Hardware and wiring

@deckingman Thanks very much for taking the time to look in

I've spent my afternoon marveling at the content on your blog. Very impressive stuff!

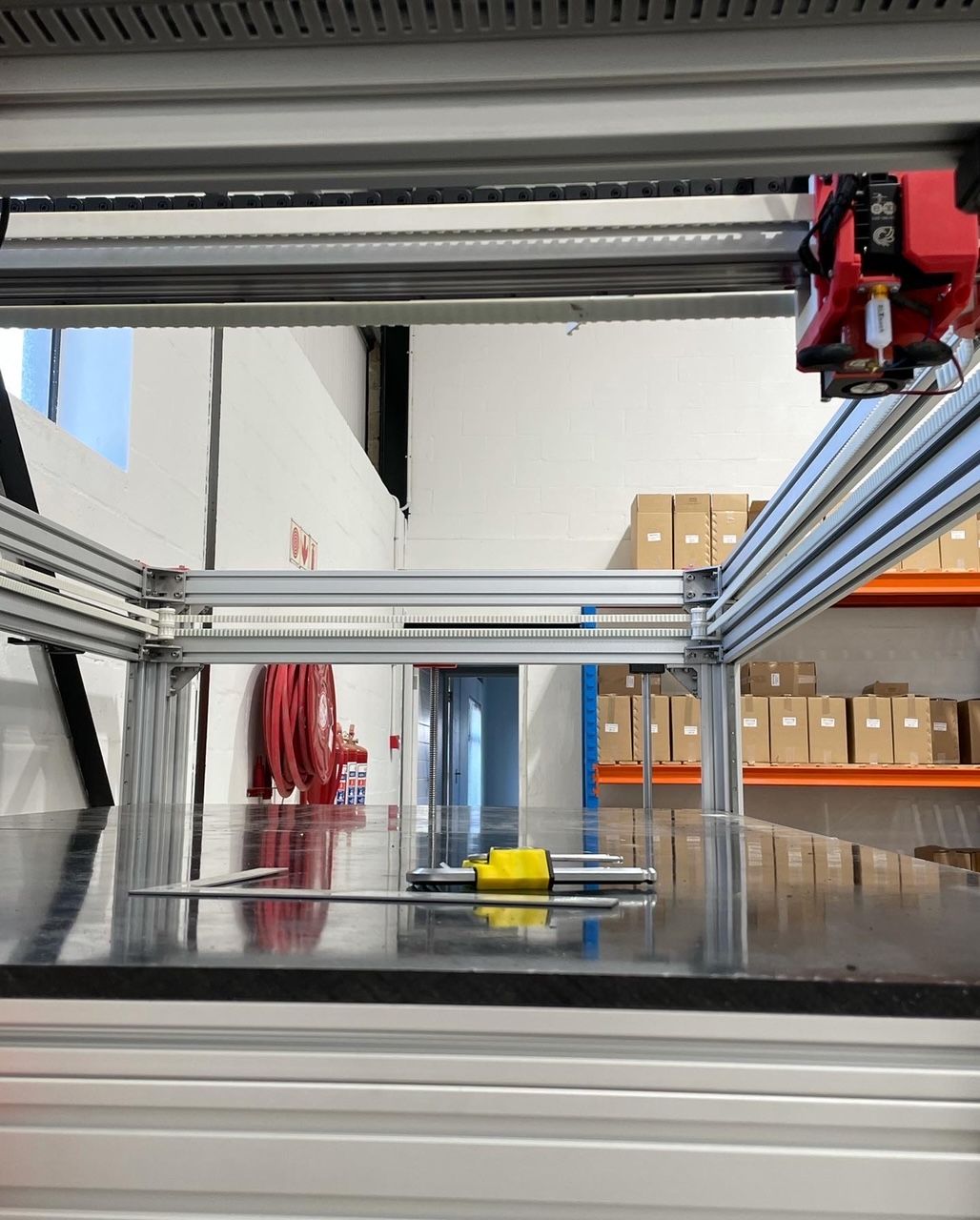

The reason that I'm looking into this is that I've built a 2000mm x 1000mm x 1000mm CoreXY printer. I'm currently running an E3D Hemera with a 110m3/s Supervolcano hot-end. (The largest non-pellet hot-end which I'm aware of?) But, I've discovered that I should have done some more boundary calculations before I plunged into this.

My issue is that my build volume is a total of 2 Billion mm3, and my "Huge" hot-end at 110mm3/s will take 18.9 DAYS to fill only 50% of this volume.

I've been looking at the pellet extruders, but they're still prohibitively expensive, ranging from $4500 to $15000. Instead, I'm looking at combining three heater cartridges from the SuperVolcano into a new heater block design and either three NEMA17 direct drive Hemeras, or a single custom made NEMA23 extruder, with three dual gear filament drives... into the same heater block, with a custom 2mm-5mm nozzle. This then got me thinking about the multiple colours at the same time.

However, what I'm really after is just massive volume flow. I'm aiming for 400mm3/s to 500mm3/sec.

I've learnt a huge amount about the configuration from your blog post, so thanks very much for documenting and explaining it so well.In terms of filament consumption, I fortunately own a production line and have an abundance of the out-of-spec colour reels (from between production colour changes) to feed the monster with

Perfectly within dimensional spec... just not colour.

Perfectly within dimensional spec... just not colour.

-

RE: Using 3HC for a Multi-Heater, Multi-Motor Extruder :) ???posted in Duet Hardware and wiring

Thanks for the replies guys.

I have no idea how I haven’t stumbled across this yet… let me go check what you’ve pointed me to quickly….

-

Using 3HC for a Multi-Heater, Multi-Motor Extruder :) ???posted in Duet Hardware and wiring

Just dropping this here for @dc42 to hopefully see...

I've had a mad thought that I want to develop, and the 3HC looks perfect to achieve it, but there are a couple practical barriers.

I either want to take three hemera extruders, plus supervolcano hot ends and route all three filament outputs into an "accumulator" for the melt which then pushes out of a custom 2mm nozzle...

OR

I want to use a single NEMA23 stepper, with a custom geared extruder and feed it through a new heater block which uses three 80W cartridge heaters and sensors.

The first option would give crazy options for G-Code colour combinations by varying extruder speeds (Each one having its own colour (R,B,Y) for example... as well as creating a flow rate of around 330mm3/s.

The second option would be a neat and compact high-flow solution that would get to huge material flow rates using standard filament and not pellet feed which requires custom extruder screws, etc.

So my question to you @dc42 is whether I would be able to "group" the heaters, temp sensors and extruder motors for Option 1 into a single E0 in the config file for easy use in G-Code? And similarly, could I group the heaters and temp sensors into a single "hotend" which uses a single extruder motor (Nema23).

Food for thought. Im frothing to develop both options and push both your and E3Ds kit to the limit... but cant quite see the route forward on the software side yet.

Any help or advice would be a huge win.

Thanks in advance

-

RE: RRF3.4 Dual Z-Axis with 1XD expansion - Height Drift/Mismatchposted in Tuning and tweaking

Thanks very much. I ran out of time to get back to the factory today but will do all of the relevant swaps tomorrow and feed back on this thread

Excited to resolve this and try to print some large carbon fibre layup tooling

-

RE: RRF3.4 Dual Z-Axis with 1XD expansion - Height Drift/Mismatchposted in Tuning and tweaking

Hi Dave, that was a ridiculously fast reply

I have verified each of the boards with M115, yes.

I’m still busy commissioning so haven’t managed to run a first print yet. I’ve got the bed to within 0.5mm corner to corner… so I have only seen the drift during a G29 so far. If I run G29, then look at the height map on the Z2 side of the bed, then run another G29 immediately after, I can see on the subsequent height map that it’s dropped about 0.5mm at Z2. (Verified this with a physical measurement too.)

I haven’t tried swapping the motors and their addresses yet… I can possibly go to the factory to try this a bit later this afternoon. I see what you’re getting at there. I have checked the mechanics quite conclusively, but I’ll do what you suggest in order to rule a line through it.

Anything else that I should be checking at the same time?

Kind regards

-

RRF3.4 Dual Z-Axis with 1XD expansion - Height Drift/Mismatchposted in Tuning and tweaking

Hi,

Thanks for developing an amazing product!

I have a 3HC main board connected to RPi4 SBC. I’ve just ‘updated’ and ‘upgraded’ the main firmware, plus all the expansion board firmware to 3.4, via the stable link. The update ran flawlessly on all the boards.

I have the SBC and 3HC connected to four (4) 1XD expansion boards and a 1LC tool board via CANBus. That are physically daisy-chained in this order… X-Y-Z1-Z2… then into the 1LC with termination resistor.

I am using 48V leadshine external stepper drives (the ubiquitous black ones). I have set all the timing to 25;25;25;25 for fault-finding purposes… still the same issue with height drift on Z2. Strangely the Z1 axis doesn’t drift.

The machine I’ve built is a big 2000mm x 1200mm x 1200mm (X-Y-Z) Core-XY printer, with a Hemera hot end and super volcano nozzle.

The CANBus connections in the panel are unsheilded, but twisted pair runs, less than 300mm long. The main CANBus cable to the tool head is an industrial spec profibus cable with terminated shield.

I know you’ll want to see my config file, but I don’t have the machine on WiFi yet and haven’t had a gap to grab a flash drive to save it out. However, everything about the machine works great, other than Z2 progressively drifting lower during G29 bed mapping.

I have checked all mechanical joints and connections of pulleys to shafts, etc. And everything is solid. I have also set the currents high enough and speeds low enough that there are no skipped steps due to under-torque. I read in a previous post that RRF3.3 had a drift issue due to CANBus latency, but that RRF3.4 had sorted this out… so I’m a bit clueless now as to why the drift is still there after the update?

Any help or advice would be much appreciated.

Thanks!