Hello handicraft friends!

Yes, I am also one of those people who want to make their own 3D-printer/or have made their own. My project took about 1 year from the first idea to the almost finished device, which is now standing in front of me. There were also some breaks and restarts.

A few key data about the printer:

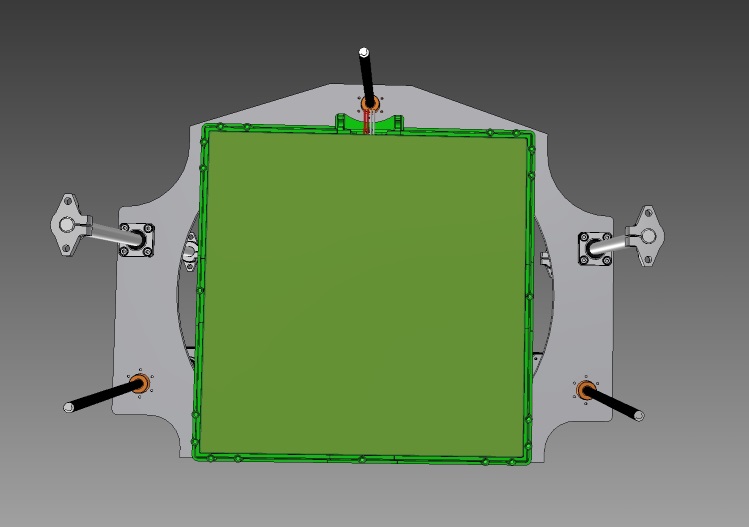

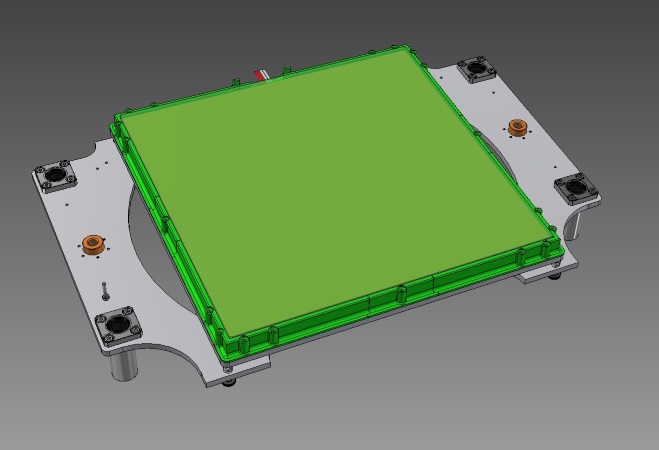

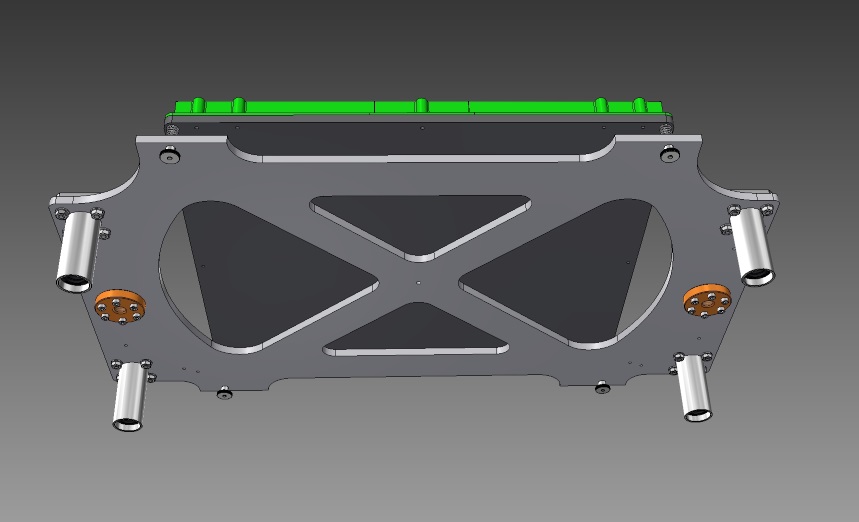

Aluminium frame, CoreXY, print volume 300x300x350mm, Duet Wifi Board, 2x360 Watt power supply (one for heating bed only), Dualprint (with one Y-Splitter), BL Touch bed sensor, filament sensors, two Bulldog extruders, E3D v6 HotEnd, 24 Volt board tension,…

Here are a few pictures of my construction, looks in real on almost so!

In the meantime, the device has been running very satisfactorily for a few weeks.

But as a developer you are never really satisfied with what you have created.

My biggest worry is about the software I've adapted for this printer.

It's all working, but is it all right? that question tortures me!

So my question, is there anyone who can take a look at my. g files?

BerTiNax

(Sorry for this english, it was translated with DeepL)