Dear community,

i already checked a few topics and try to find my answers in the documentations. But unfortunatly i did not get all questions answered. So maybe some of you have a similiar setup or has the knowledge to help me through.

My Setup:

- Killerbee 1510

- 4x Nema 23 Motors

- Duet 3 Mainboard 6HC

My plan is to run the duet in the standalone mode at first. I have setup the cnc already and now next steps are wiring and the correct setup of the mainboard.

So, my main questions go to the RRF, i think the steps afterwards with adding some GCodes to bring the firmware to the cnc mode is clear so far.

- I have four drivers, 1x X, 2x Y and 1x Z ... should i add an extra driver E0 in the configuration?

- The Endstop Pin - i think i will add the same Endstop Pin to both Y-Drivers.

- My Endstops have three cables but the connectors on the board five ... where i have to connect and what i have to choose in the configuration drop down?

- i think the rest on the page I/O Mapping is not important yet.

- On the Motors Page i am completly lost, what are the recommended values for my motors?

- The Endstops i think i can find out, but maybe someone with the same setup knows already the correct configuration.

Maybe i have forgot a few important points, i know that i have a lot of questions. I would be very happy if someone can support me and help me to bring the killerbee to cut

If there is a need of more information, please let me know.

Cheers

Bowski

https://configtool.reprapfirmware.org/Start

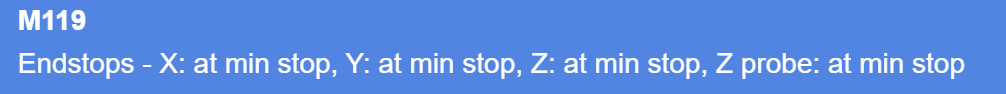

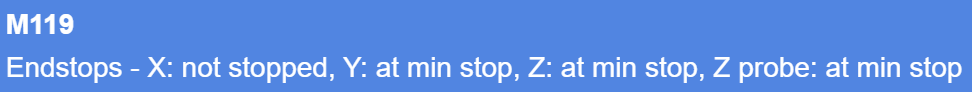

I switched the Endstop of the Y-Axis to Y Positive and inverted the endstops in the configuration.

I switched the Endstop of the Y-Axis to Y Positive and inverted the endstops in the configuration.