@T3P3Tony This is only semi-on-topic because I have a 713-maker effector plate on my Rostock Max v2, not a Smart Effector.

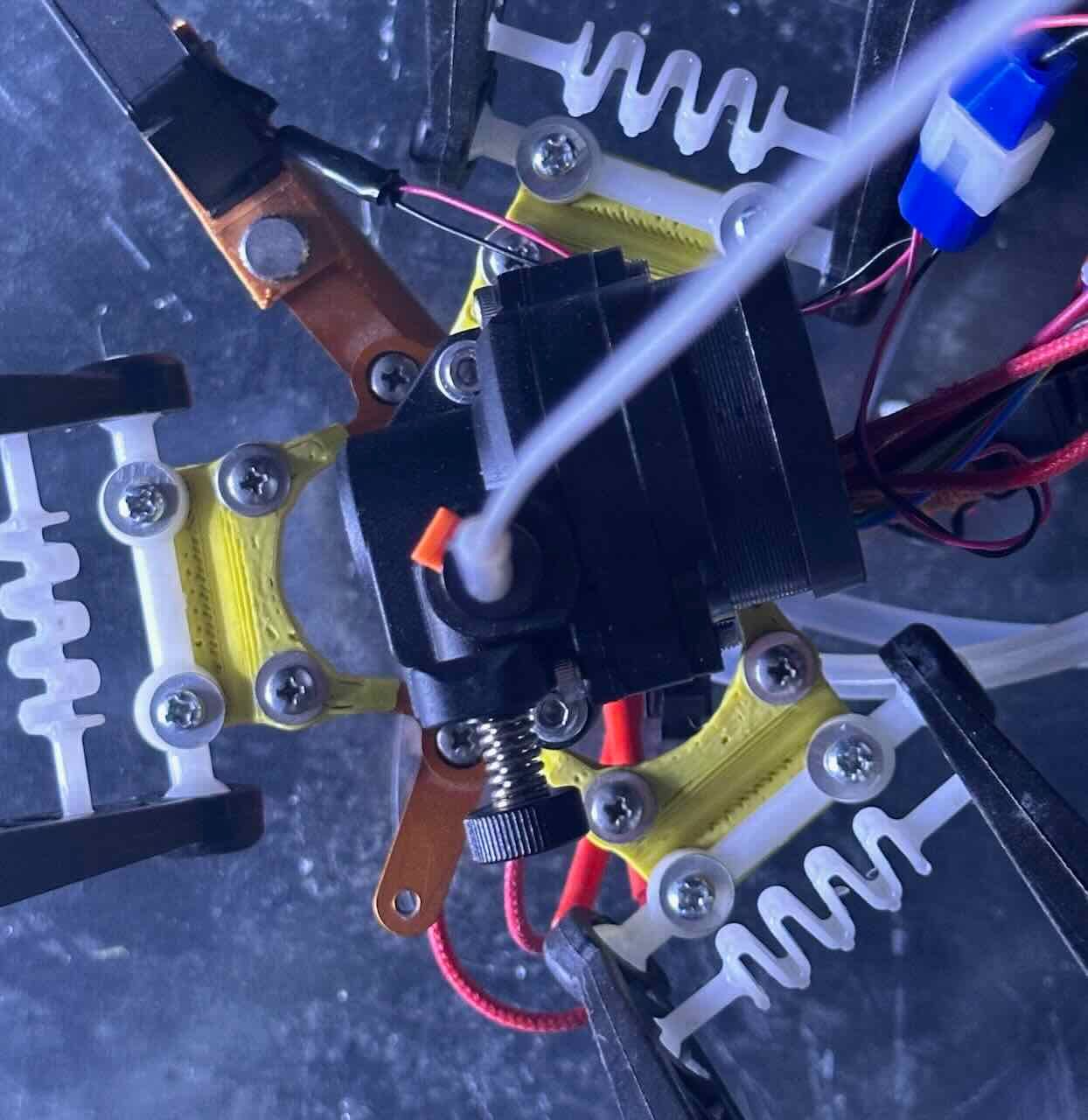

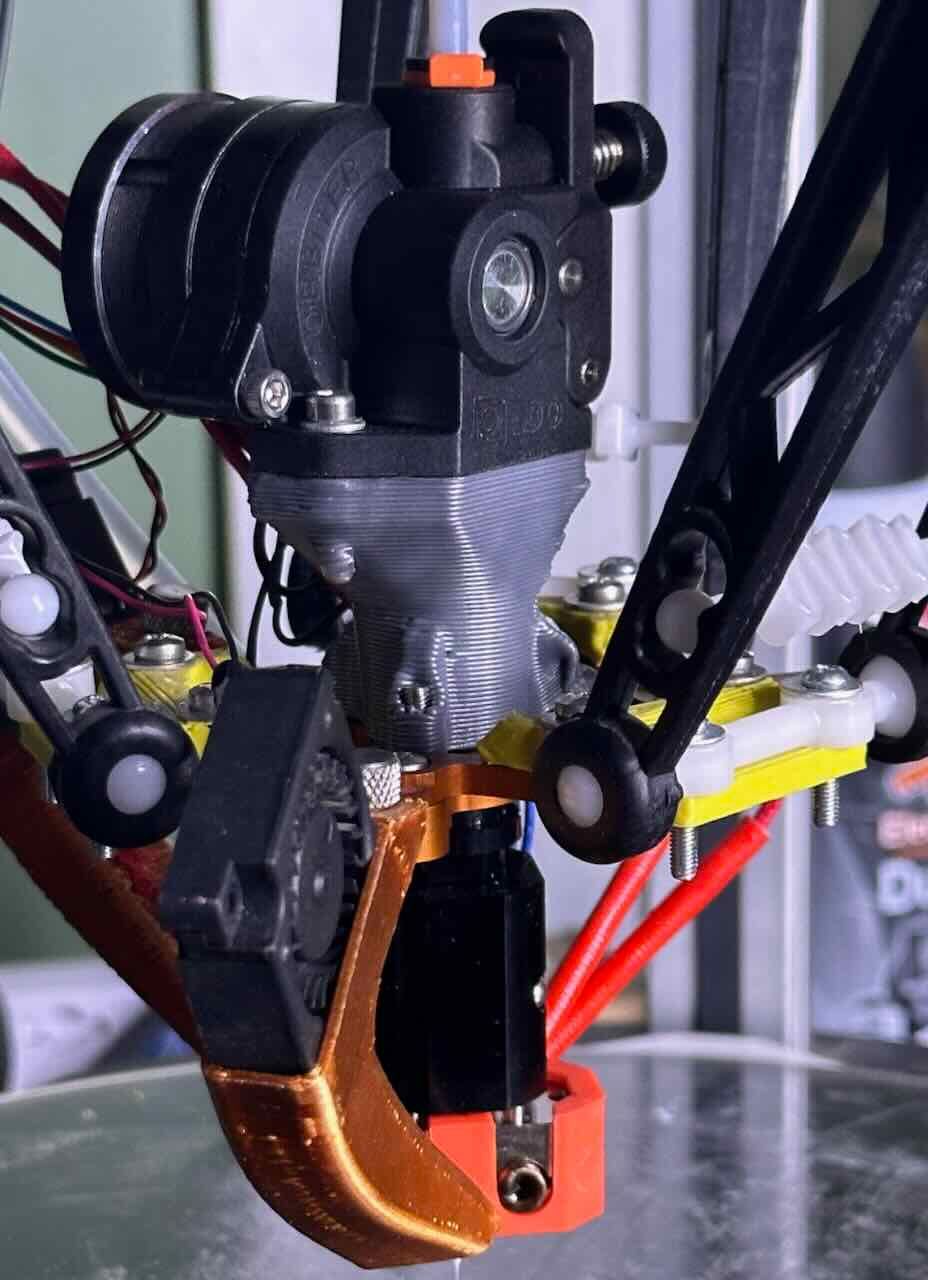

But I have cobbled together a real-world implementation of an LDO Orbiter V2.0 on that effector. My solution was to rotate (20º) and raise the extruder (25mm) to clear the arms. A short length of bowden tubing within the extender keeps the filament guided between motor and extruder. It turned out that this arrangement cut down on the build envelope more than desired (allowed the motor to hit the arms at the top extreme of the plate) so I moved all of the effector's arm attachment points outward by 13mm (increasing the size of the effector plate).

Raising and rotating the motor might have deleterious effects on momentum/vibration/tilt that outweigh the fact that it allows for a slightly smaller effector plate that still fits the motor between the arms. But it's working for me for the moment.