@zapta For those who may be curious how this turned out, I was not able to discern what type of component I needed to replace. I did the manual check

for zener diodes and that test did not show a zener diode. The T7 tester I bought for this is also confused. It has shown IGBT, PD mos, dual diodes and cross connected diodes. It's not consistent at all with this one component. I asked a person I know that use to repair tv's and he said it could be a custom part made just for that company. This might explain why the markings don't

show up anywhere. Anyway, I found my receipt and the company replaced the faulty unit. Thanks to everyone that chimed in, I promise not to burden the forum with this sort of thing in the future.

Posts made by Idodgeads

-

RE: Help with component identificationposted in General Discussion

-

RE: Help with component identificationposted in General Discussion

@zapta I have nothing else to do today so this will be my goal. I really hope after all the trouble, it's not something else wrong with the camera entirely lol.

Thanks for the help. -

RE: Help with component identificationposted in General Discussion

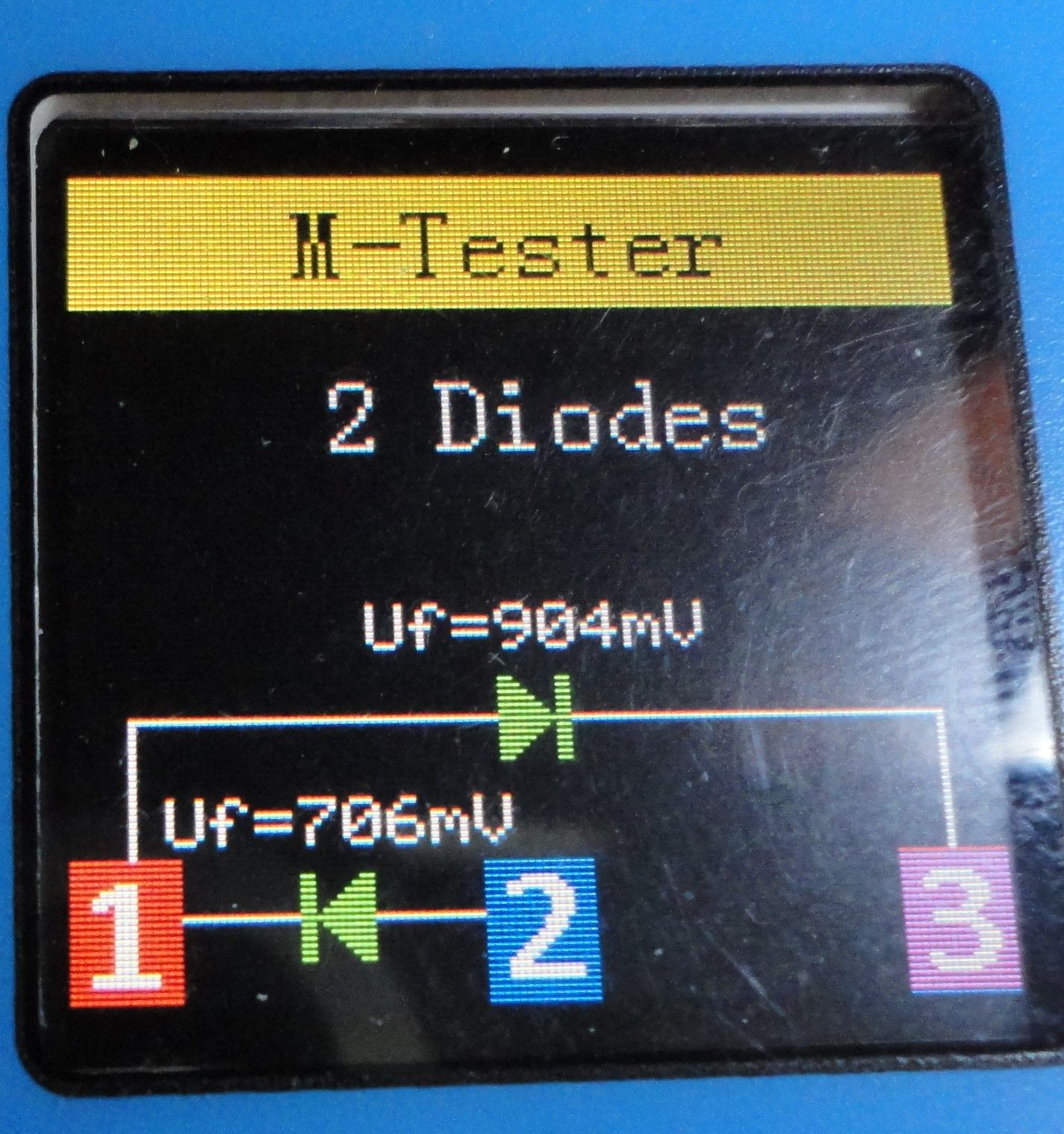

@dc42 Its just the inconsistency of the tester I have. I found on one of the databases

the RDt component is listed as a dual zener diode but my tester does not show it in a

configuration I can find to purchase. This confuses me. I contacted the company, they won't help other than replace the unit with proof of purchase and evidence of the corrosion. Well, I already removed the corrosion in my first repair attempt. The proof of purchase I doubt I can find sadly. -

RE: Help with component identificationposted in General Discussion

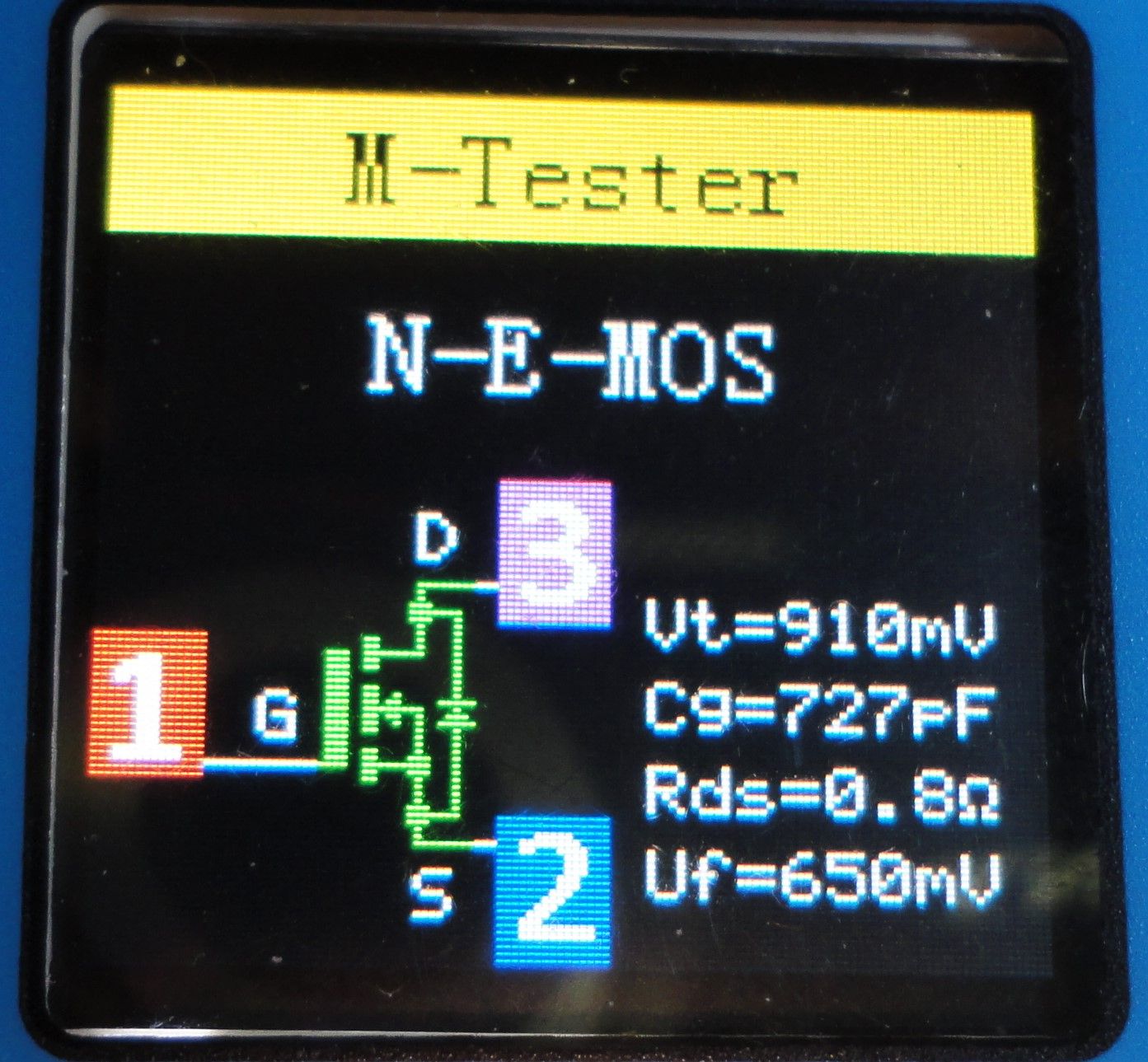

@moth4017 Thank you! That fills in the blank for the mosfet, now I have to figure out

the other component. I may reach out to the company for a schematic. My chances are slim

but its worth a try. I can't find a dual zener diode with that configuration. It could be my new tester is lying to me and it's something completely different.Thanks again,

-

RE: Help with component identificationposted in General Discussion

@zapta So it took longer than expected to get the tester but here's what I got.

I don't think the tester is very good with zener diodes. It has 3 terminals just for those but if you connect a standard diode there and test, it shows it as a zener as well. With that said, I think RDTE could be a duel zener...I just don't know how to tell. Finding suitable replacements is where I need help.

-

RE: Help with component identificationposted in General Discussion

@zapta I think I can make contact with what's left of the terminals. They're broke off flush

but they are there. I ordered the T7 tester, it should be here next week. I hope the tester will take the guess work out of this project. I'll report back when I get the results. -

RE: Help with component identificationposted in General Discussion

@dc42 Thanks everyone for the help. I wasn't sure if this would get much attention since it is a bit off topic. Preventing the burning down of one's house is a noble endeavor. I went through this with my duet 2 wifi board as it was purchased used and abused. Multiple fried components, things didn't work. I was able to fully restore the board with the help of reading this forum.

I was wondering if an LCR meter would be of any help here? I don't know the scope of what components those meters will identify or identify correctly. I'm sure caps, resistors, diodes and the usual stuff but what about zeners and more complex fets and things?

I may order one if I can find a way to get leads attached to the components

to test them. Missing one leg on each isn't going to help matters....maybe the

use of a needle as a probe? -

RE: Help with component identificationposted in General Discussion

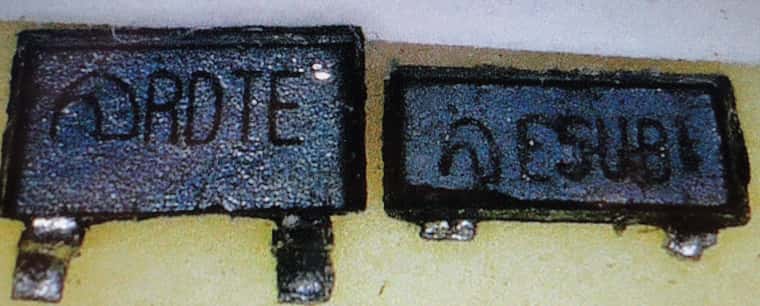

@moth4017 They both had 3 legs, the corrosion removed the third. I've looked

all over for that logo and the markings and I can't find anything definitive. I'm seeing this

more lately where i'm trying to fix a device but the markings on components dont lead anywhere. If I could find a broken one of these cameras on ebay, I might go that route unless someone has some insight here. Thanks for your interest! -

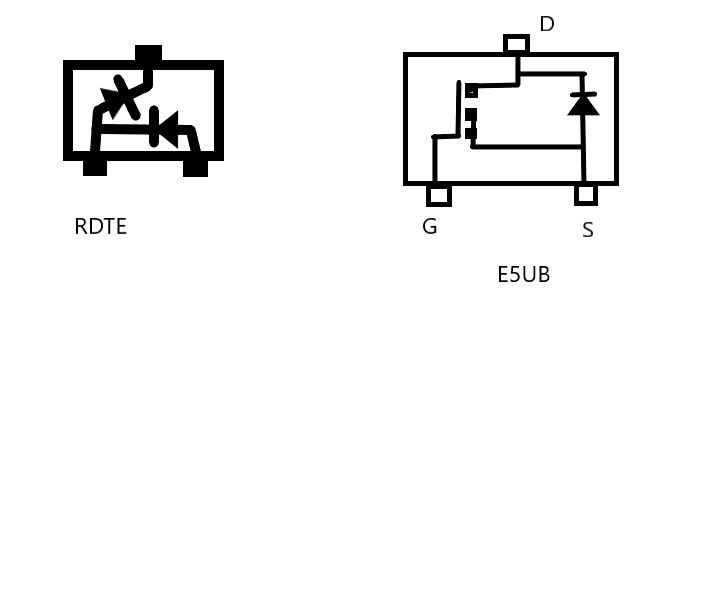

Help with component identificationposted in General Discussion

I know there's some electronics wizards here, I need a hand. I had an incident

a few weeks ago where the solder joints failed on the mosfet board that runs my build plate. This could have caused a fire. I want to use a solar powered automotive back up camera as a monitoring device for my printer. The one I have quit working since the last time it was used. Corrosion has ruined two components on its circuit board and I can't find info on these anywhere.Here's a pic of the components. They read RDTE and E5UB. Any help finding what these are or suitable substitute components will be appreciated greatly.

-

RE: SD card corrupted?posted in General Discussion

@infiniteloop

It was the sd card. I was lucky I had a config backed up on my tablet that was fairly recent. I did have to redo everything else though, macros, firmware and so on. I'm going to make a backup sd card as soon as I get everything tuned right.Thanks again,

-

RE: SD card corrupted?posted in General Discussion

@infiniteloop

Ok thanks, I'll try that later today. I have a feeling its the sd card but I've never seen one

rewrite the file names and delete the data like this has. -

RE: Lgx lite defective or flaw?posted in General Discussion

@infiniteloop

No problem, I understood what you meant. Can't start out at wide open settings, gotta build up to them. Unfortunately, something has happened to either my sd card or my duet wifi board. I posted the symptoms, maybe someone will know what happened. -

SD card corrupted?posted in General Discussion

I turned on my printer and the fans run constantly. I have no control over anything, can't

connect to the DWC. Took the sd card out and put it in the computer. The files on the card are now named 9 !9 )9 9 <9 }9 19.Any idea what has happened here?

Thank you in advance,

-

RE: Lgx lite defective or flaw?posted in General Discussion

@infiniteloop

That's good advice, I'll get some new PLA and try it. So far, the correct settings for the hotend have improved things greatly with the new PETG I have and the old PLA is working now too as long as the lgx is set to TPU mode. I was never expecting to get

vzbot or hevort speeds out of this printer. I was just wanting something that doesn't take 3 hours to do a benchy like my old setup did. -

RE: Lgx lite defective or flaw?posted in General Discussion

@infiniteloop

So lesser quality filament equates to poor consistancy not age. I honestly don't know how this filament was stored before i bought it. I didn't know anything about 3d printing at the time I purchased all of this. I thought it would be a fun challenge to complete something someone else gave up on.

So lesser quality filament equates to poor consistancy not age. I honestly don't know how this filament was stored before i bought it. I didn't know anything about 3d printing at the time I purchased all of this. I thought it would be a fun challenge to complete something someone else gave up on.I may try another extruder like the vz hextrudort. It will mount the same and I have all the BMG parts already. I will lose the mount for the MFM and accelerometer unless I could modify the motor plate and have someone machine it(no cnc here) I thought I had this project done but some of yesterdays prints had layer shifts at only 100mms. My xy assembly weighs only 798g and I'm using 1684mac .9 steppers. Maybe go back to 1.8 motors?

-

RE: Lgx lite defective or flaw?posted in General Discussion

@o_lampe

I will have to toss out some of it, a few rolls are so brittle it reminds

me of uncooked spegetti. I have about 25 rolls of all colors and types, it'd be a shame to not salvage some of it. I did discover that I had not updated the B and C values for the new hotend. I did that and retuned. The hotend temp seems stable now so that may be part of it.

The rest of my problems are no doubt the inconsitant diameter of the filament. With the extruder in the solid position, sometimes it will pull the filament in with force and sometimes just lightly pinching it with fingers will stop it. Its totally random. Here's a pic of what it did yesterday, it starts the layer out fine then makes this gnarly line then the MFM pauses the print.

-

RE: Lgx lite defective or flaw?posted in General Discussion

I was able to contact Bondtech and they confirmed the lgx lite is designed for properly

sized filament. My issue is I received a lot of filament when I bought my printer and it's at least two years old now. Even though most of it is still sealed, there are some rolls that have been opened that are getting brittle and have decreased some in diameter.I was told for undersized filament, I could use the TPU setting on the extruder. This has worked ok so far without the motor getting hot or any other issues. The lgx lite is pretty well built. I thought at first my issue was cold extrusion. I installed a rapido hotend and even though I pid tuned it, I'm still not sure if I have the right settings in config.g for that hotend. My old hotend was a v6,

Overall, I'm happy with the lgx lite. My only wishlist item would be a "middle of the road" setting between the solid and tpu settings for when you don't have optimal or consistent sized filament.

-

Lgx lite defective or flaw?posted in General Discussion

Sorry to bother you all about this but the bondtech support portal isnt working. I just got my printer back together after a rebuild of the x/y parts and my lgx lite is failing to extrude any filament that is not consistently around 1.74mm.

I have a new roll of hatchbox petg that measures 1.71 and even with that, I only get about half way through a small print without it failing to extrude. I do have the lever in the middle position for solid filaments. I have a new rapido hf hotend as well. I have only been able to get a successful print using a roll of repko Pla that measures 1.74mm. Any filament below 1.71 won't extrude...I have an old roll of pla + that's 1.68mm(shrinkage?) it won't work at all.Do I have a defective lgx or is this a design flaw in the preset tension mechanic of the extruder? Has anyone else had this issue? Any and all recommendations are welcome. I'm really stumped here as I've built my printhead around this extruder on a vzbot print carriage, so my options are really limited.

-

RE: Redesigned the MFM housingposted in Filament Monitor

@lo-fi Here's my print of your redesign. I'm really happy with it. I followed your settings and it printed great. A little sanding and trimming was required to get the halves to fit but they fit well. I used pla on the housing and pla+ for the idler. Once I redo the

print head and x axis on my printer, this is going on there over the top of an lgx lite on a custom mount. Thank you for putting forth the effort and making your design public

-

RE: Redesigned the MFM housingposted in Filament Monitor

@lo-fi

No problem, I would be glad to test your design. My printer is slow but its pretty accurate if I get the slicer set right.

As I'm not an electronics wizard, I'm wondering about grounding the shielding in the usb cable. Does it need grounding at one end, both ends? Maybe a ferrite choke would also help here. I wish I had an oscilloscope still, I'm sure that would show any noise on the data wire of the mfm. I'm thinking of making up a shielded cable for my bltouch. I just replaced my v1.0 with a new v3.1 and I still have random high spots in the height map but most of the wonky behavior the old one had is gone.