So i just got my Duet Accelerometer(new) installed on my ender 5+ with a 3 mini 5+.

But after the hole evening trying and reading and measuring im a bit lost.

M955 P0 C"spi.cs2+spi.cs1" I14 q500000

Error: M955: Accelerometer not found on specified port

So summarize what i did;

ive read:

https://docs.duet3d.com/en/Duet3D_hardware/Accessories/Duet3D_Accelerometer

https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_Accelerometer

https://docs.duet3d.com/User_manual/Reference/Gcodes#m955-configure-accelerometer

Uses this wiring diagram

https://docs.duet3d.com/duet_boards/duet_3_mini_5_plus/duet3_mini5+_v0.5-v1.02_d1.5_wiring.png

And did this

- Installed the hardware

- Ive used the supplied 10 28awg pre connected cable .

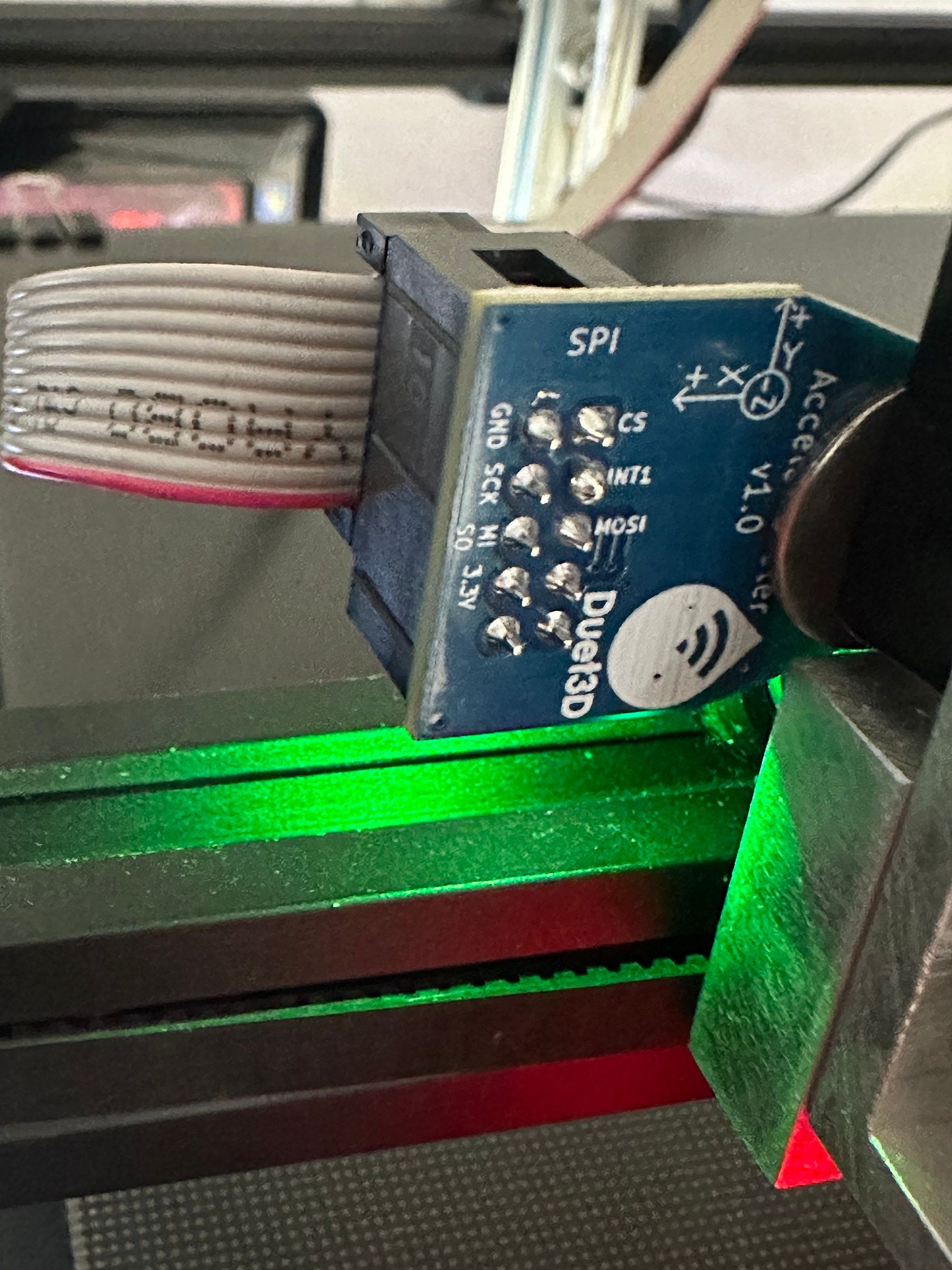

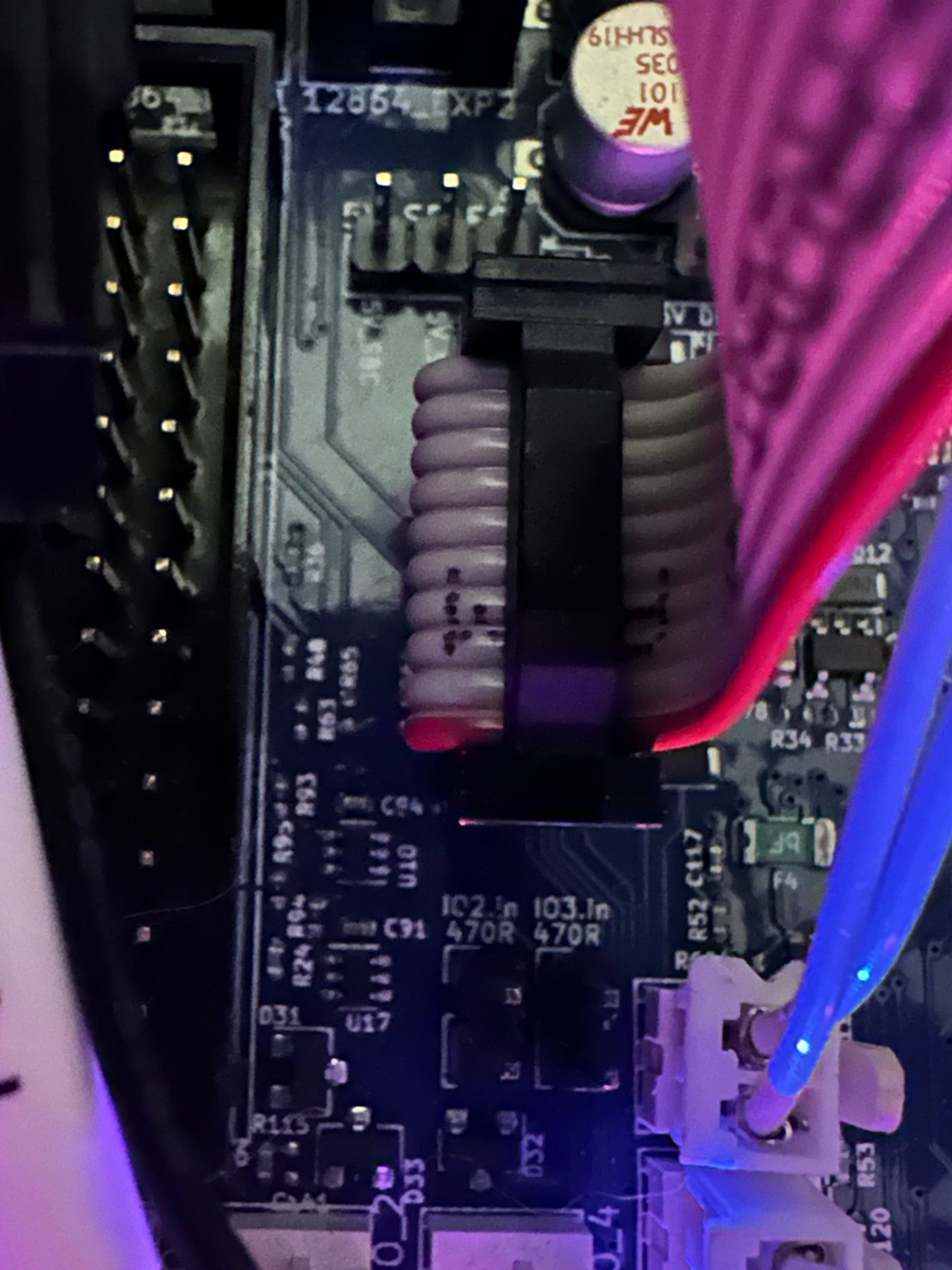

- Connected it to the de SP1 daughterboard connection

- Checked connections and cables

*Put in config;

M955 P0 C"spi.cs2+spi.cs1" I14 q500000

- Ive added the Q later because of my reading, but i cant seem to find it.

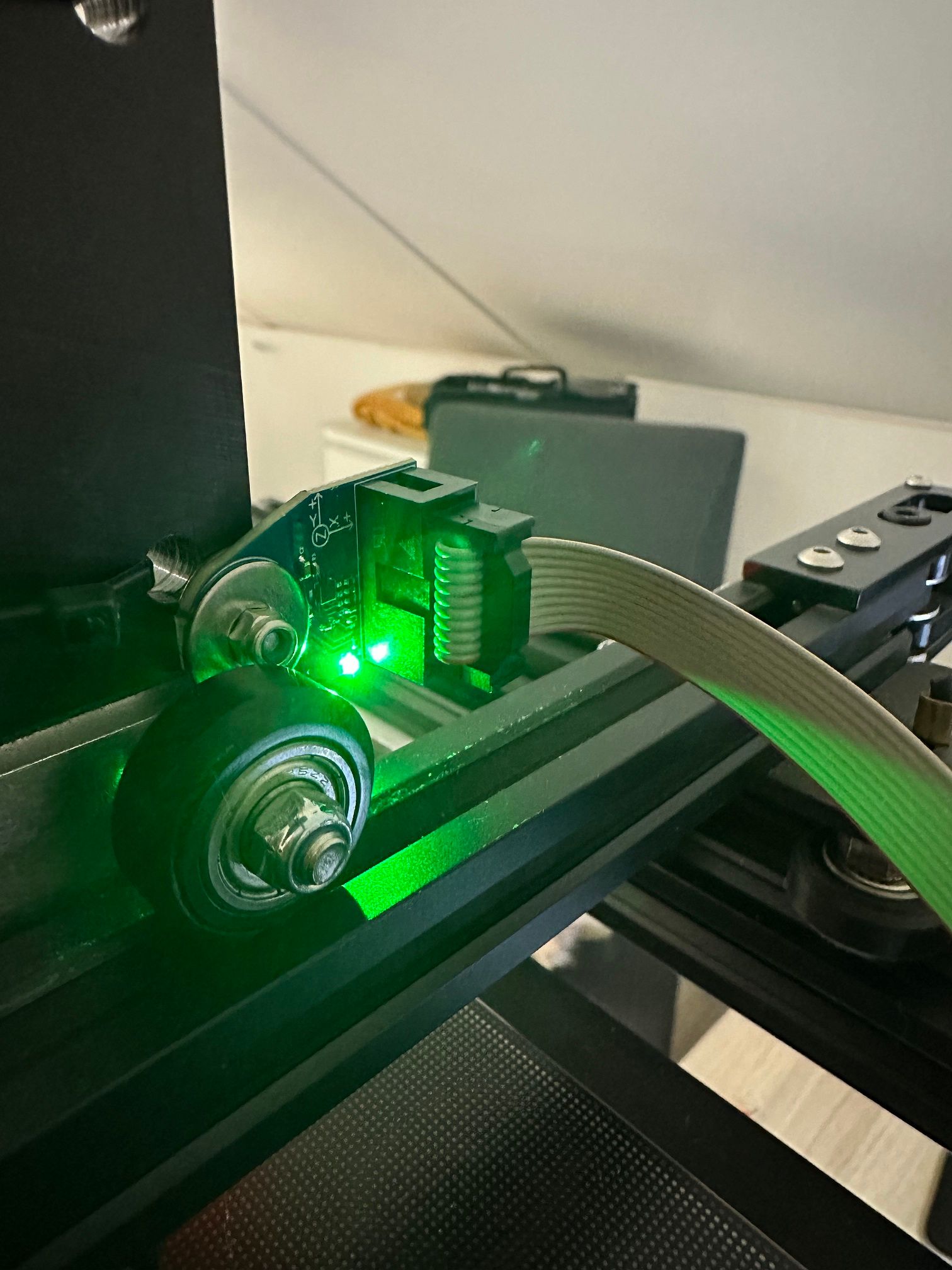

- I do have 3.3V on the accelerometer and the green LED is burning.

- double checked the wiring, and i rather not cut my wiring because i intent to use it for my Paneldue i7 relocation when im done with input shaping.

I assume the supplied cable (1meter?) is good enough the make it work? Or do i need to go MacGyver and add resistors/thin film etc?

Some pictures;

and i added config and m115 command for firmware;

m115

FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.5.0-beta.4 ELECTRONICS: Duet 3 Mini5plus Ethernet FIRMWARE_DATE: 2023-06-08 23:40:14

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Wed Dec 13 2023 21:57:46 GMT+0100 (Midden-Europese standaardtijd)

; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Ender 5 Plus" ; set printer name

; Network

M552 P192.168.178.96 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.178.1 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards (Z Axis Left)

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M569 P0.4 S0 ; physical drive 0.4 goes backwards (Z Axis Right)

M584 X0.0 Y0.1 Z0.2:0.4 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E394.26 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E500.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X350 Y335 Z400 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"!io5.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin !io5.in

M574 Y2 S1 P"!io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !io6.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

M558 P9 C"io3.in" H2 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-33 Y-5 Z3.768 ; set Z probe trigger value, offset and trigger height

M557 X25:315 Y40:310 S19.3:18 ; define mesh grid

; Bed adjustment screw locations

M671 X-33:383 Y166:166 S8 ;Z pivot points are at Left(-33,166) and Right(383,166)

; Heaters

M308 S0 P"temp0" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C

; Extruder Fan

M950 F1 C"out3" Q500 ; create fan 1 on pin out3 and set its frequency

M106 P1 C"Extruder" S1 H1 T60 ; set fan 1 name and value. Thermostatic control is turned on

; Part Fan

M950 F0 C"out4" Q100 ; create fan 0 on pin out4 and set its frequency

M106 P0 C"Part" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Input Shaping accelerometer

M955 P0 C"spi.cs2+spi.cs1" I14 Q500000 ; Oriantation 14(+X to -X) all wires connected to temp DB connector, no temperature daughterboard

; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory