All -

I've made the two changes as instructed:

M558 P1 X0 Y0 Z0 H30 F1000 T5000

G1 S1 X400 Y400 Z400

Progress so far:

-

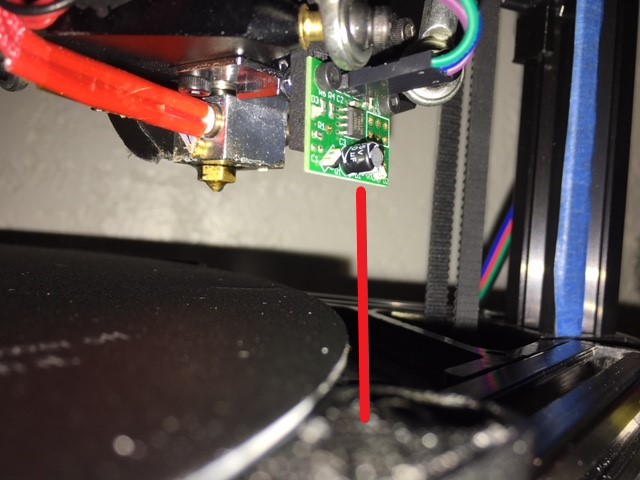

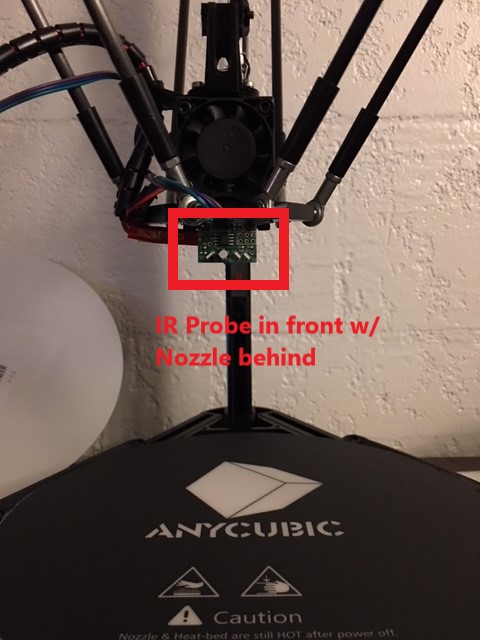

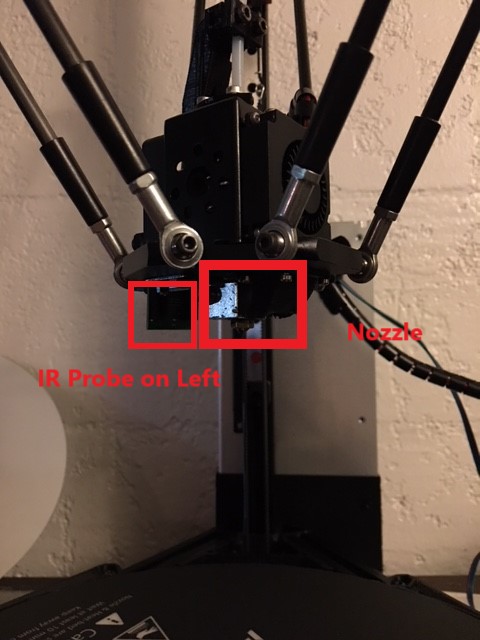

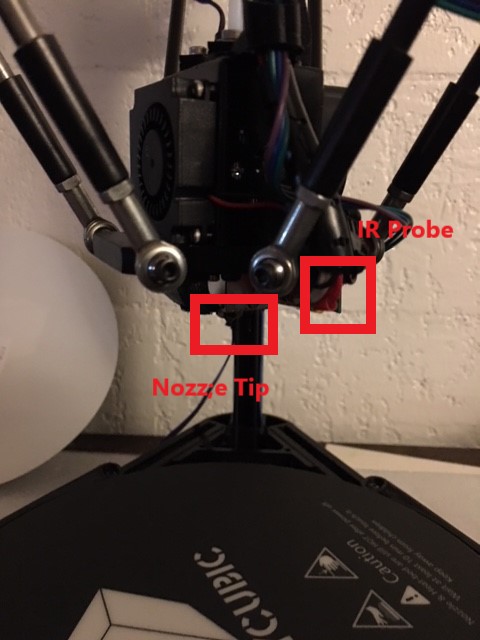

The auto probe calibration works with the Z probe except for the far XY edge where it drags along the bed (the IR sensor is positioned off the side of the bed - it sees nothing so the nozzle eats the bed). This is amazing progress, though. Because reterminating the IR Z probe connectors got it to work (in theory).

-

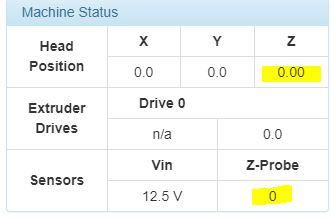

However, it looks like the printer still thinks that Z=5.3 is the same thing as Z=0. When I try to print something like the XYZ calibration cube, the nozzle drops down to Z5.30 (5.3mm above the bed) and spews filament onto the bed. Recalibrating (and entering M500 to save settings) doesn't resolve the issue. What might be causing this stubborn behavior in the printer?

Here are my config files:

config.g:

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R134 L270 B85 H285 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them

; Network

M550 Pduettest

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Z-Probe

M558 P1 X0 Y0 Z0 H30 F1000 T5000 ;I1 ; Set Z probe type to DC42 and the dive height + speeds

G31 X0 Y0 Z2.02 P500 ; Set Z probe trigger value, offset and trigger height

M557 R130 S20 ; Define mesh grid

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E96 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops

; Heaters

M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S275 ; Set temperature limit for heater 1 to 275C

; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

; Automatic saving after power loss is not enabled

M501

; Custom settings are not configured

config-override.g:

; This is a system-generated file - do not edit

; Delta parameters

M665 L270.000 R134.000 H285.000 B85.0 X0.000 Y0.000 Z0.000

M666 X0.000 Y0.000 Z0.000 A0.00 B0.00

; Heater model parameters

M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1

M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0

bed.g:

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40

M561 ; clear any bed transform

G31 X0 Y0 ; don't want any probe offset for this - ADDED 5/21/2018

G28 ; home the printer

M401 ; deploy the Z probe

; bed.g file for RepRapFirmware, generated by Escher3D calculator

; 10 points, 6 factors, probing radius: 105, probe offset (0, 0)

;M98 Pdeployprobe.g

G30 P0 X0.00 Y105.00 Z-99999 H0

G30 P1 X90.93 Y52.50 Z-99999 H0

G30 P2 X90.93 Y-52.50 Z-99999 H0

G30 P3 X0.00 Y-105.00 Z-99999 H0

G30 P4 X-90.93 Y-52.50 Z-99999 H0

G30 P5 X-90.93 Y52.50 Z-99999 H0

G30 P6 X0.00 Y52.50 Z-99999 H0

G30 P7 X45.47 Y-26.25 Z-99999 H0

G30 P8 X-45.47 Y-26.25 Z-99999 H0

G30 P9 X0 Y0 Z-99999 S6

;M98 Pretractprobe.g

; DEFAULT SETTINGS - Set by the RepRapFirmware Wizard

; Probe the bed at 3 peripheral and 0 halfway points, and perform 3-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

;G30 P0 X0 Y84.9 H0 Z-99999

;G30 P1 X73.53 Y-42.45 H0 Z-99999

;G30 P2 X-73.53 Y-42.45 H0 Z-99999

;G30 P3 X0 Y0 Z-99999 S3 ;H0

M402 ; retract the Z probe

G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bed

homedelta.g

; homedelta.g

; called to home all towers on a delta printer

;

; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40

G91 ; relative positioning

G1 S1 X400 Y400 Z400 F1800 ; move all towers to the high end stopping at the endstops (first pass)

G1 X-5 Y-5 Z-5 F1800 S2 ; go down a few mm

G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass)

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

G90 ; absolute positioning

;G1 X0 Y0 F6000 ; move X+Y to the centre

Any suggestions? Thanks!