Thanks. As soon as I saw that line I commented it out. Testing now.

My firmware version is "2.02(RTOS) (2018-12-24b1)" with a duet 2 wifi

Thanks. As soon as I saw that line I commented it out. Testing now.

My firmware version is "2.02(RTOS) (2018-12-24b1)" with a duet 2 wifi

My config-override contains the following.

; config-override.g file generated in response to M500

; This is a system-generated file - do not edit

; Delta parameters

M665 L339.470 R158.955 H443.311 B145.0 X-1.155 Y0.379 Z0.000

M666 X-0.410 Y1.448 Z-1.038 A0.00 B0.00

; Heater model parameters

M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B0

M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00

I have a BossDelta 300 that I need to disable all the heated bed stuff for. The heated bed was removed from the machine.

;M307 H0 B0 ; Heated Bed (H2)

;M305 P0 T100000 B4388 R4700 H30 L0 ; Bed thermistor

In the config.g file I commented out the lines for the heated bed but I still get the following error and the heated bed still shows in the UI with a 2000C temp.

Error: Temperature reading fault on heater 0: unknown temperature sensor channel

My whole config.g file is as follows.

Please help.

M550 PBOSSdelta300 ; Printer name

M555 P2 ; Gcode Output Type

M552 S1 ; Enable Wifi

M575 P1 B57600 S1 ; PanelDue Comm Setup

G21 ; Work in millimeters

G90 ; Send absolute coordinates

M569 P0 S0 ; Drive 0 goes forwards (X)

M569 P1 S0 ; Drive 1 goes forwards (Y)

M569 P2 S0 ; Drive 2 goes forwards (Z)

M569 P3 S1 ; Drive 3 goes forwards (E0)

M569 P4 S1 ; Drive 4 goes forwards (E1)

M574 X2 Y2 Z2 S1 ; set end stop configuration (all end stops at high end, active high)

;M665 R150 L351.1 B145 H510 X0 Y0 Z0 ; INJ. MOLDED ARMS delta radius, diagonal rod length, printable radius and homed height

M665 R150 L339.47 B145 H455 X0 Y0 Z0 ; CARBON FIBER ARMS delta radius, diagonal rod length, printable radius and homed height

; Y X Z are tower angle offsets

M666 X0 Y0 Z0 ; end stop offsets in mm

M350 X16 Y16 Z16 E16:16 I1 ; Set 16x micro-stepping w/ Interpolation

M92 X200 Y200 Z200 ; Set axis steps/mm

M92 E182.0:182.0 ; Set extruder steps/mm

M906 X1500 Y1500 Z1500 E1200:1200 I50 ; Set motor currents (mA) and idle current %

M201 X1400 Y1400 Z1400 E5000 ; Accelerations (mm/s^2)

M203 X10000 Y10000 Z10000 E18000 ; Maximum speeds (mm/min)

M566 X700 Y700 Z700 E2000 ; Maximum instant speed changes mm/minute

M106 P0 H-1 ; Part Cooling Fan

M106 P2 T50 S0.7 H1 ; Heat sink fan

;M307 H0 B0 ; Heated Bed (H2)

;M305 P0 T100000 B4388 R4700 H30 L0 ; Bed thermistor

M305 P1 T100000 B4388 R4700 C7.06e-8 H30 L0 ; Hot end Thermistor

M563 P0 D0 H1 ; Hot end (T0), drive (E0), heater (H1)

G10 P0 S0 R0 ; Hot end operating and standby temperatures

;Dual Extrusion Code

M563 P1 D1 H1 ; Hot end (T1), drive (E1), heater (H1)

G10 P1 S0 R0 ; Hot end (1) operating and standby temperatures

;STRAIN GAGE PROBE

M558 P5 I0 A2 S0.05 R0.4 H20 F2500 ; Strain gauge probe settings

G31 P100 X0 Y0 Z-0.15 ; Probe trigger and offset values Glass Plate Only

;G31 P100 X0 Y0 Z-0.5 ; Probe trigger and offset values for FabLam Flex Spring Steel PEI on Glass

M557 R140 S30 ; defualt bed mapping

M501 ; Load saved config values

T0 ; Select Tool 0

M375 ; Load height map

Hello,

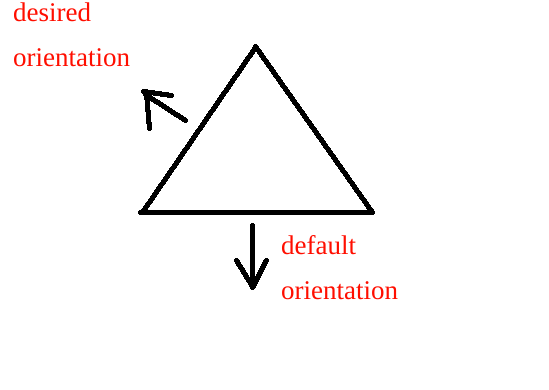

I have a SeeMeCNC BOSS delta printer and I would like to re orient the machine from its default settings.

I don't want to re wire the machine or mess with the pin configuration. Is there an easy way to rotate the default coordinate system to change what would be considered the front side of the machine? Possibly a single gcode command?

See attached illustration.

@Veti

I was really hoping to not have to do hardware changes on the base printers we are getting from SeeMeCNC. They come stock with duet wifi boards and we take the machines and add automatic ejection hardware and cloud print management software before reselling the machines.

@bearer using a network connection in my use case would not be practical. The board is being consumed in to a product that the user should not have to do a bunch of janky network set up. The raspberry pi in this use case is intergrated in to the end product and is the sole network connection the user has to set up. The way the system is written gcode is not pushed to the machine from a central server but rather fetched by the raspberry pi and sent line by line to the printer. Shooting the gcode file over to the duet sd is not desired as the raspberry pi is being used to control other parts of the printer directly as the pi and associated extra hardware are designed to be universal and work with a variety of printer control boards.

In my particular use case we are making printers with automatic part ejection systems. It would be too much to ask the user to configure one printer to use 2 different networking tools to make it work. As to pushing the data to the sd card. This is not a viable option. If the usb connection drops out it will not be able to continue print autonomously.

Hello,

I am with Autodrop3d. We have been building 3d printers that use a raspbery pi to send gcode to the control board in a rostock max v4.

Currently use a raspberry pi to send gcode to the printer over USB. The gcode sender program requires an acknowledgement from the board for each line and currently works over the USB. Unfortunately we have some problems with EMI that knocks out the USB interface from time to time. It would be beneficial to allow for changing the default from using USB to using some serial pins. I understand that you can send gcode over the serial interface normally used for the display but the board dose not send acknowledgements.

Pushing the GCODE over a wifi or Ethernet network connection is not an option in my use case.

So right now there is no way to use the displays serial pins in stead of the USB interface with normal response messages.

@dc42 said in Using Panel duet pins as serial interface:

M408

What dose this mean for using the serial pins as the primary interface with "OK" responses from the board. I am in a bit of a jam here and using USB is not an option in my situation. Is this marlin compatibility mode an option? Dose that change the way the firmware works or just the response msgs back on the serial interface?

Thanks

-Mike.

Hello,

I have a duet 2 wifi board that came installed in a Rostock v4 printer. I am attempting to use the serial interface on these pins to send a line of gcode and get back a response from the printer. I have modified the config.g file to have "M575 P1 B9600 S0" in it and it seems to be receiving and executing commands sent over the serial pins now. My problem is that I am getting no feed back at all from the board. Normally there is some kind of a msg back from the board indicating that the command completed. I am not getting any thing.

Is there some thing I have to do to enable acknowledgement msgs from the board?

Any help would be greatly appreciated.

Could you describe this buffering a bit.

I have done similar things in the past hooking up to an old fashioned ramps board on on this thing is is all a bit confusing.

Do you know if the serial pins that would normally come off of the USB to serial converter on a normal ramps board are exposed? Might be easier to try and find them.

Hello,

I am working on a project that really requires that I send data over real serial. Not USB to serial but honest goodness real serial I/O pins.

It appears that there is a serial interface intended for uses with an LCD display. I would like to re purpose that.

If you know what to change to make it so I can send just regular good old fashioned gcode over this interface. No line numbers or checks sums. That would be really great.