I thought I'd share something that I've been working on for a while (since October  ) and made public earlier today - MillenniumOS, which is an "Operations System" for RRF 3.5+.

) and made public earlier today - MillenniumOS, which is an "Operations System" for RRF 3.5+.

There's further documentation for the system, and the operations it implements, on our (Millennium Machines) documentation site, and I made a video a while back (while developing it!) of how the system works in practice - I'll be making more of these now that the repository is public including example videos of each probing operation.

MillenniumOS is a combination of 3 things:

- A G-Code dialect

- An RRF addon consisting of a set of custom G- and M- codes and system macros (tool change, pause, resume etc) that implement the gcode dialect and

- Post-processors for Fusion360 and FreeCAD (Realthunder branch until FreeCAD releases a version packaging Python 3.11)

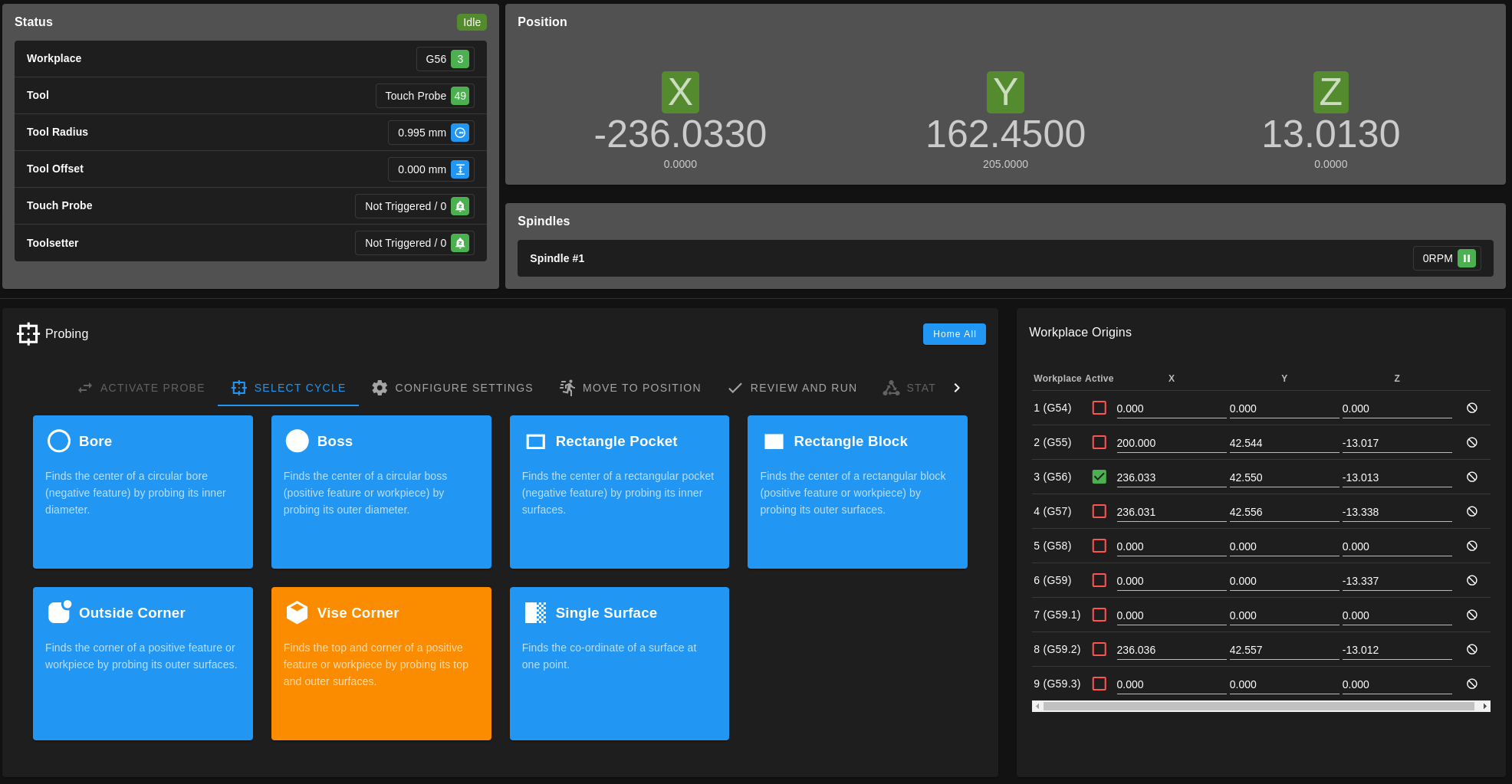

This addon implements a bunch of CNC features designed to allow novice operators to approach their first cuts more safely and in a guided fashion, including:

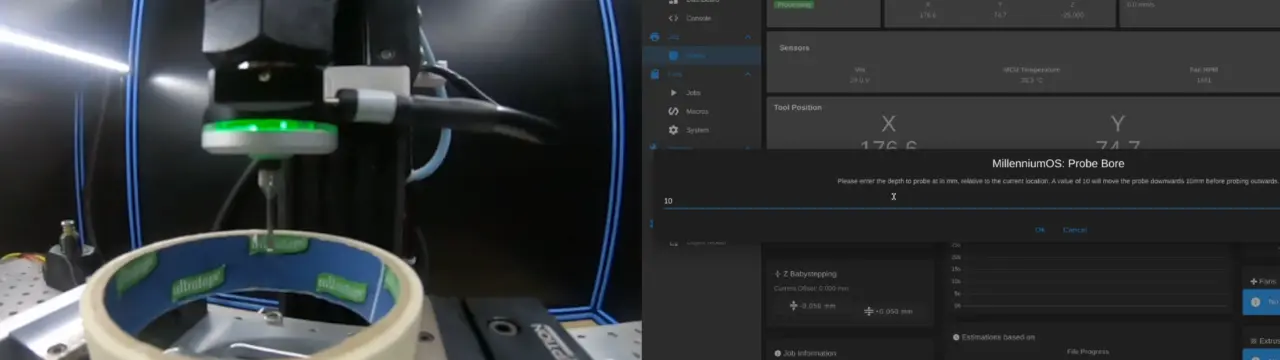

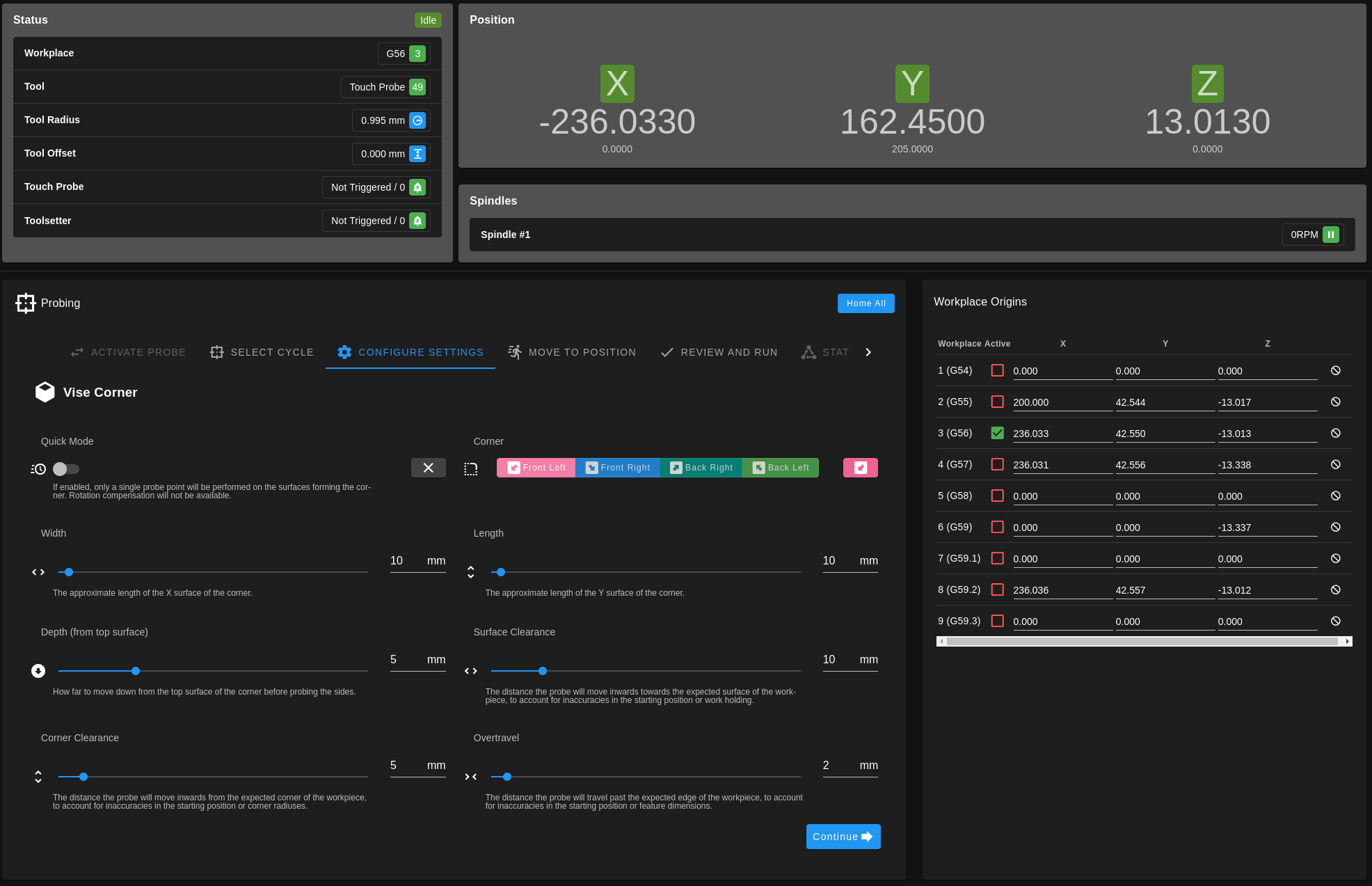

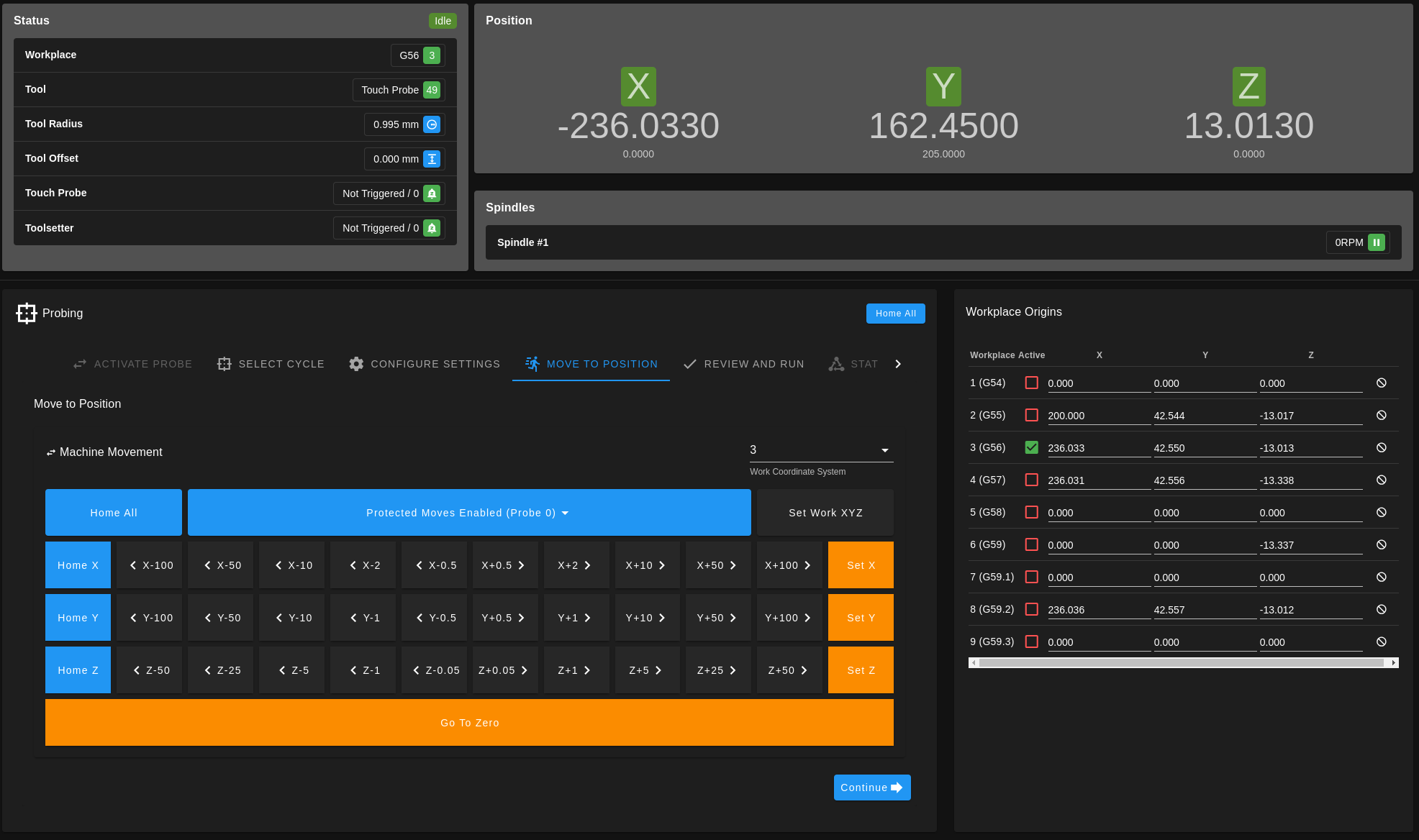

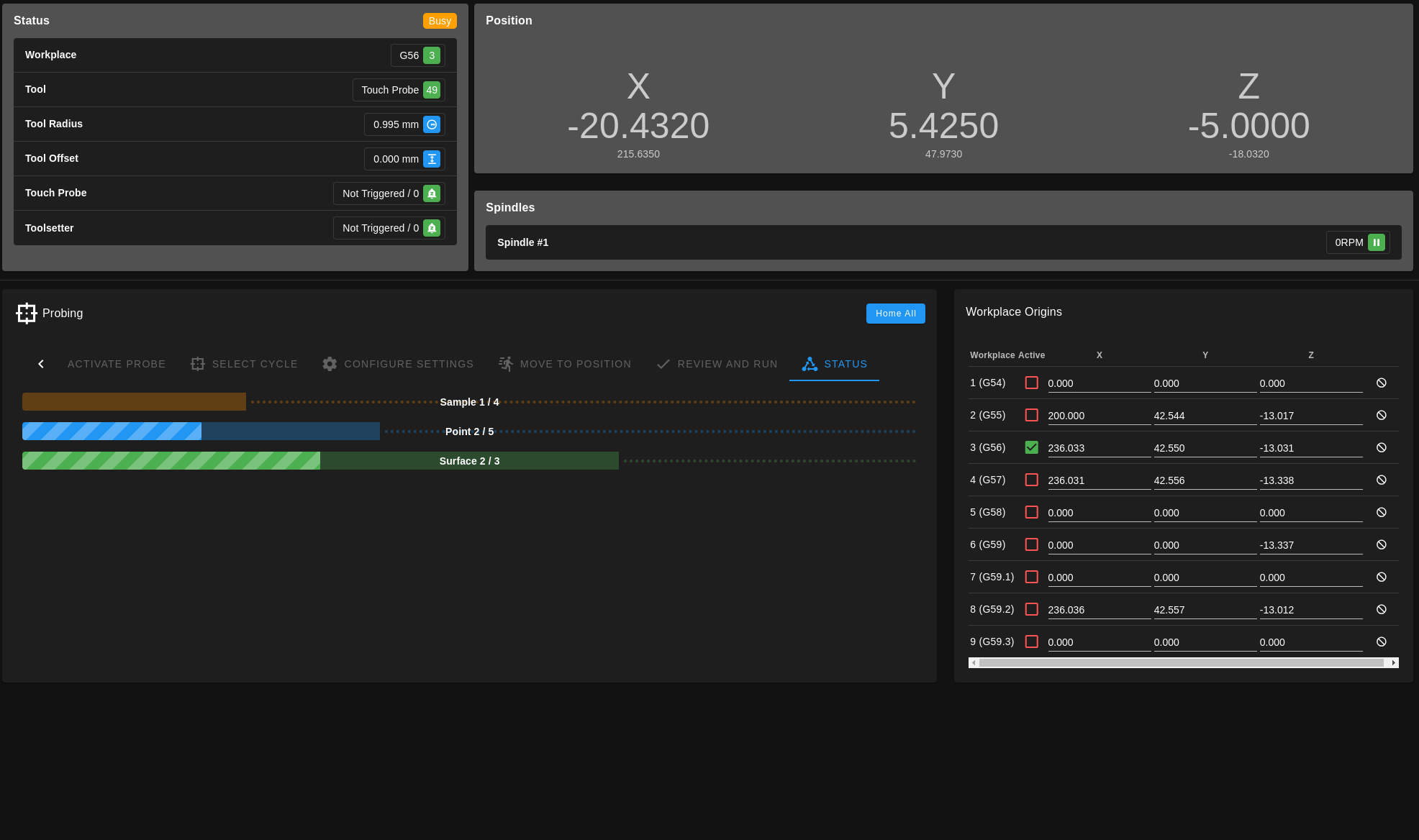

- Guided workpiece probing (Bore - shown above, Boss, Rectangle Block, Rectangle Pocket, Outside Corner, Vise Corner, Single Surface) using both a touch probe and manually with a datum tool. Includes touch probe deflection and radius compensation as well as datum tool radius compensation.

- Protected moves when using a touchprobe so during travel moves, the machine will stop if an unexpected collision was detected.

- Workpiece rotation calculation on certain probe cycle types which will be used in future to apply

G68transformations. - Tool changes with tool length compensation using a toolsetter, or re-triggering a z-probe on the workpiece if no toolsetter is enabled.

- Parking in Z and optionally X/Y for easy access to the table.

- Pause and resume with spindle control and delay.

- Variable Spindle Speed Control, which adjusts the spindle RPM up and down within a range to avoid resonance between the tool and workpiece.

- Configuration is handled using a Wizard process that runs on first-install, guiding operators through the process using RRF dialogs. Includes a guided procedure to measure touch probe deflection.

- Probing cycles gather information required using RRF dialogs as well.

The base design choice of this system is that all complex functionality is implemented as RRF meta gcode - there are some great post-processors for RRF but these all seem to take the approach of implementing rather complex functionality in the post-processor itself, rather than doing this directly in meta gcode.

One of the benefits of taking the MillenniumOS approach is that the post-processors are relatively simple, and implementing wider post-processor support to target this gcode dialect is much quicker than re-implementing all of the functionality in a new post-processor to support a different CAM package.

One thing I wanted to do with this was to make manual probing easier / safer. Not everyone has a toolsetter and touch probe, but the maths to calculate probing points and origins is the same whether using a touch probe or not - so MillenniumOS can guide the operator through manual probing in exactly the same way it would use a touch probe.

The probing macro is actually the same, but runs different underlying macros to trigger either a touch probe move or a M291-dialog-driven manual move. This avoids the RRF jog window as much as possible as I've found it too easy to hit the wrong button - the manual probing will only ever move directly towards or away from the surface that needs to be probed - it won't accidentally move up or down, or along the wrong axis.

You can see an example of how the probing cycles are the same between touch probe and manual probing in this video, and one of the early testers made a video of running through the installation and machining using the MillenniumOS post-processors and macros here!

This addon is designed to work with our (Millennium Machines) open-design desktop CNC mill, the Milo, but it should work with any machine that has the axes configured in the same direction (i.e. Moving tables with Y max when the table is at the front, X max when the table is at the left, and Z min when the spindle is at its' lowest point). I'd be interested to hear from anyone who decides to try and use this on a machine that isn't the Milo.

On machines that don't have the axes in the right direction (X and Y only, Z minimum must be the lowest spindle position), then certain settings like corner names or surface names will need to be changed as these would be back to front depending on which directions your axes move.

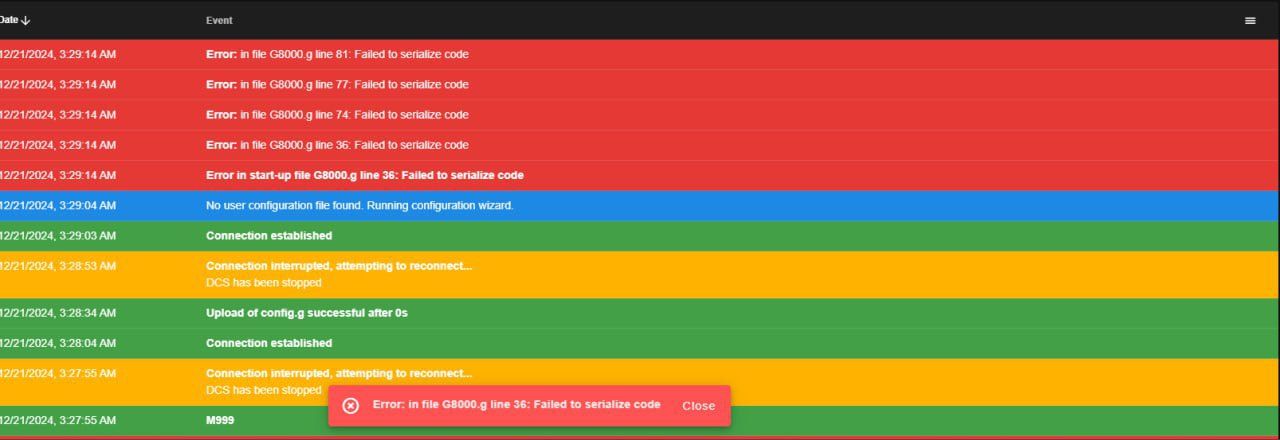

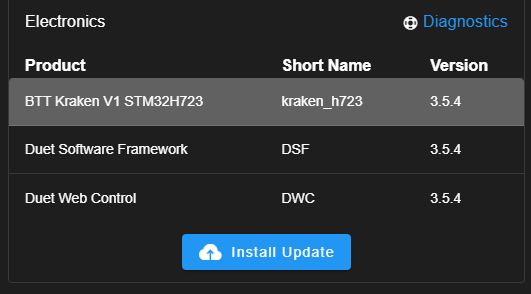

I've found while developing this that I have been pushing the capabilities of RRF and some of the boards we've been testing on (specifically the stm32f407) so this has been a really fun project and a bunch of the Duet and Teamgloomy guys have been a great help in tracking down a bunch of issues, so if you guys are reading this thank you so much for your help - this is why I was coming up with all sorts of random questions and issues and everything else.

My goal has been to reduce the learning curve for those just getting started with machining and hopefully what I've developed here helps with that - this is only a first public release and I'm hoping I'll be able to continue working on this more in future!

- luckily no broken probes or major issues and got some great feedback as well.

- luckily no broken probes or major issues and got some great feedback as well.