What useful things have you printed on a 3D printer?

-

For me at least, a 3D printer is the perfect companion for those who like to do electronic projects.

Electronics are my toys from when I was born, so this hobby persists to this day. Every project needs some kind of enclosure.

I'm thinking about an Arduino/Raspberry Pi. As these boards can interact with many peripherals, 3D printing is indispensable for that "professional" touch.

There are generic "project boxes," generic ones, injection molded. But it is something generic. As an enthusiast, I think that every project, custom and unique.

If in some shop I see something that catches my attention, most of the time in my mind comes an "I can do it better", for me at least.

For an enclosure for that board, sensors, lights, and everything else, it is one thing to mount it with double-sided tape (maybe), and it is another thing that every LED, sensor, and internal layout has its own nut, bolt, and its own place to be mounted to.

Another benefit of 3D printing in this area is the freedom to choose your own color schemes and different materials you can print (e.g., matte vs. glossy vs. CF).

I've seen very good projects done using generic components and plastic components, but in my opinion, those can't beat your personal idea, and the fact that this technology can really bring a thought to reality just as you imagine it.

-

I started my 3D printing ”career” 7 years ago with an RFID controlled time recording terminal - a USB / HID device attached to some iMacs in a medium-sized factory. Bought the casings, but needed mounts for display, Arduino and other components within. So I bought a CR10 bed slinger, instantly replaced the controller with a Duet, subsequently re-printed most of my printer, modding it heavily (water-cooled Chimera, heated chamber, etc.).

As I just print mechanical parts, often for outdoor use, I almost exclusively use PETG. For my electronics, I mostly rely on Arduinos of some kind, often using several of those communicating over CAN. Here are some random projects of mine, all using 3D printed parts:

Hydraulic work platform / scaffold - conversion to electronic / remote operation:

- Mounts, brackets and housings for electronics

Wheel loader - conversion to electric drive:

- Analog levers for hydraulic controls

- Hand throttle

- Dashboard

- Mounts for power supplies and electronic components

Lawn tractor / mower:

- Battery case

Kneading machine:

- Reinforcement mount

”Mobile socket” / outdoor power station:

- Battery housing

- Control panel

- Covers, mechanical connections

- Mounts for cable reel, heat sinks, electronics etc.

Gas burner:

- Clip for alternative cartridges

Thermostats:

- Housings, mounting parts for MCU, display, controls

Bikes:

- Base for bike stand

- Mount / housing for USB lighting system

- Replacement keypad on the handlebar (E-Bike)

27" iMac to Thunderbolt display conversion:

- numerous internal mounts for Arduino, Audio and other components

-

@dc42 the most useful thing I have printed on my 3D printer is....another 3D printer, of course! And then with that new 3D printer, I plan to make all the plastic parts required for build a PrintNC CNC router.

-

@infiniteloop these sound awesome - do you have a blog or other place you document these projects?

-

@elmoret Sorry, no time to blog as long as I make

-

@dc42 the first useful thing I remember printing was a clip. A simple clip. I had a PC case that I really liked - an aluminium ($$$ at the time) Lian Li ATX or similar PC case. It had a removable front that was just clipped on with four clips; you removed the front in order to get at the fan filters for cleaning. Anyway, after a while the clips broke, one by one. At some point the front really didn't stay on any more and I was considering the $$$ options for a new case and all the headaches... Then I bought my first 3D printer. The clip was a simple extrusion, which I took a photo of from above, and used some web based software at the time to extrude it, and then printed it. No CAD even. Worked a treat and saved the case from landfill.

Since then, I have printed so many things. I learnt early on that brackets and adapters were the unsung heroes. Never even thought about that as a use for a 3D printer until I owned one.

-

@dc42 I lately printed funnel-like adapters for my woodworking machines. Many machines needed wood chip/dust extraction of a different diameter.

-

During COVID I was given the task of making the home aquarium totally silent , the sound of trickling water apparently has adverse affects on some people.

Using PLA printed a number of parts. A water shoe for returning water to flow over silently and allow a wood piece to be attached to imitate a submerged root, an under gravel grid filtration system and a holder for the water valves to control water pressure to the top and bottom filters.

The end result was going from a noisy tank I needed to constantly coax along and monitor to keep everything healthy to one that thrives, plants grow fast and fish have multiplied and grown, unaffected by PLA in the water . I don't think I could have done it as quick any other way. The bonus is I don't worry about keeping the fish alive any more

About to redo the tank as the first accessory printed that supports a wood piece has cracked after 4 years of total water submersion.

One side effect of actually printing for me has been learning to move from 2D drawing to designing and thinking in 3D , for me that was a big thing and having a printer to print out your concept and hold it in your hand really helped me to learn and to think better in 3D

-

Around the house, the most useful item I've printed was a chopping board holder designed to snuggly fit each of our different boards and stop them falling over in the cupboard. Now half my firends and family also have a set!

Outside, I have an old Reliant Scimitar as a project car which had a lot of non-standard parts on it and has needed several 3d printed items. I started with simple gauges on the dashboard, but have now got a few bits in the engine bay including the intercooler mounts and the throttle mount on the engine (both out of some high temp filament). Next big item will be a full intake manifold which I'd probably then fibreglass wrap for extra strength, toughness and sealing. I've been quite impressed with how the 3d printed bits have held up with the abuse the car gets when I take it on track!

-

I 3D printed a motorcycle crank puller and a tool for installing gearbox lock rings when I was rebuilding my motorbike engine.

I also used it to produce prototypes of an axial to radial caliper adapter to fit a radial motorcycle brake to my axial forks, before having the real bracket machined locally.

Now it gets used to make parts and develop new machines for the Millennium Machines team.

-

repair / reinforcement brackets, wall holders to turn rods into hangers, all kinds of connectors; emergency replacement wheels for 1:32 slot cars, self watering plant pots, shims, spacers, wedges, skadis holders of all kinds for a sewing station, ....and some more I forgot about

-

The most useful print I've ever done is a shoe horn -

A quick print using PLA on BambuLab printer.Use mine once or twice every day.

https://makerworld.com/en/models/122098?from=search#profileId-131553

-

Many things, upgrade parts and mounts for bikes, timetrial starting clock, pool shot timer, electronic telescope focuser conversion, workshop storage bins/trays/holders, battery adapters, camera flash reflectors, speaker mounts and things I've long since forgotten about.

-

A set of adapters to mount deck railing lights on new deck.

Prototype plastic brackets to mock up an air conditioner compressor on a 1967 MGB. After several iterations the plastic was used as a template to cut brackets in aluminum.

Oil catch can mount for a1946 MG-TC

Several fabric holders for wife's sewing machine.

Timing gauge for wife's long arm quilting machine

Jewelry display mounts

Housing for an O2 sensor display.

And, of course, parts to update my other printer -

Several lamps, a bread box, bicycle disc brake sanding tool, bicycle fender mount, Nespresso capsule dispenser, Pax Plus vaporizer handle, Ikea Frakta bag handles, physical therapy rubber band handles, incandescent lamp replacement for microscope illuminator, camera and cell phone mounts for telescopes, microscopes, and 3D printer, in-drawer knife block, wire twister tool, Wago lever nut mounts, several furniture feet, a Van de Graaff generator, 3D printer spool holders, coin and wallet holder for Prius console, replacement for failed Prius trunk release cover, stand for S&B Mighty vaporizer, bottle cover for Uberlube, parts for my sand table and 3D printer, parts of a 20 liter soda syrup tank agitator, replacement pushbutton caps for an old preamp, brackets for a "cat ladder", cat puzzle toy, aperiodic tile array pieces and storage box, cutting board drying rack, dental x-ray sensor wall mount, brackets for mounting curtain rods,

racks for torx and hex screwdrivers, bicycle air horn bracket, coasters, cable hold-downs, bicycle chain guard, One Wheel electric skateboard car stand, ear-savers and bias tape making tools for COVID masks, compartmentalized refrigerator storage box, binaural mic earpieces, manual coffee grinder electric drill adapter, antique radio dial belt, Audi and BMW jack pads, white board marker and eraser holder, and many more.Bread box and cover:

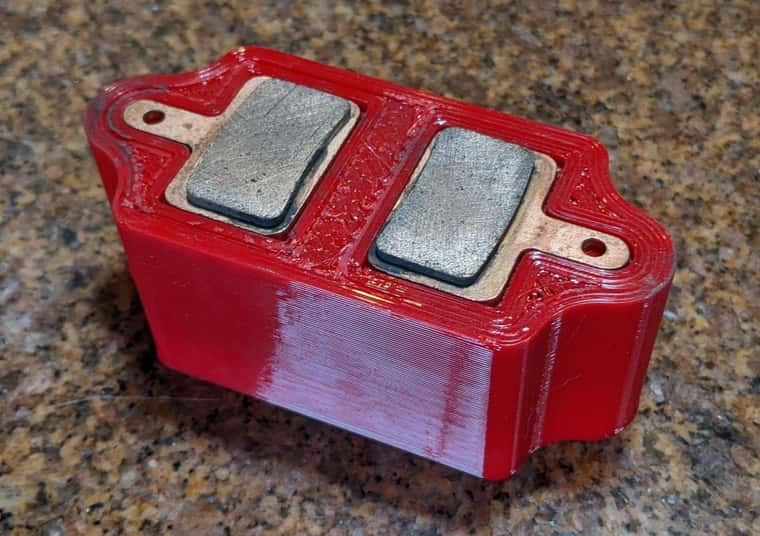

Disc brake sanding tool:

Bicycle fender mount:

Button caps for old preamp:

Lamps:

Another lamp:

Coin and wallet holder for Prius console:

-

Likely the most useful was a bear spray, quick release (important!) holder. I used to mountain bike in Montana

https://www.printables.com/model/137420-bear-spray-holderThe best cost-saving was a dash component for an older Range Rover. You can imagine what the stealership would have charged!

The simplest (but nonetheless useful) was new, square, washers for a toilet seat mount .

-

My 3D prints are paired 99% of the time with a custom 3D design in Autodesk Fusion. I almost never download a model to print.

My parts:

Loads of utilitarian things for around the house - custom hangers for tools in the garage and shower cleaning supplies. A made to fit basket for the kitchen sink to hold and drain a sponge. Stands for art pieces. Cleats to wrap the pull-cords on window shades. Custom corner fittings for electrical conduit, The housing for a heater to keep the hummingbird feeder from freezing in winter. Handles for hex wrenches.Many repair parts to extend the life of something - replacement foot straps for a stationary bike (TPU), replacement sprinkling spout for a watering can, replacement hinges (PETG) and latch (TPU) for a picnic cooler, bracket for a replacement switch.

Proof-prints for personal engineering challenges (can I design X in Fusion?) - I think these technically fall into the "artistic/ornament" category. Gear trains for a Copernican orrery, a 1ft diameter spherical shell 6mm thick (smooth on the inside and outside), various print in place sliders and hinges.

And of course, parts and accessories for a 3D printer.

-

Apart from sundry brackets, housings etc around the house, most of my efforts are devoted to custome skirted lure designs for marlin fishing.

"Traditional" lures have a head cast from resin. Shaping the face creates a swimming action and having holes through it helps create a bubble trail to help attract the fish.

It's a big ocean out there, so anything out of the ordinary for a predator gets attention and hopefully an "I wonder if I can eat that" moment.I don't try to replicate traditional lures. We all know they work and resin being heavier has different properties.

I try to design things that have never been tried before.

Flexibility of design and fast prototyping allow me to create weird shapes to see what they do to the action as different areas grab the water.

Easy creation of complex air pathways allow differing bubble trails.

I can combine tings like bibs (normally only used on non game fishing lures) and add pivoting sections.Some designs work, others are abject failures , but it's all fun.

Unfortunately I don't own a game boat, so usually only do one trip a year chasing marlin.A few designs

Checking out theaction and bubble trail

A marlin checking out the spread.

Underwater camera towed in the lure spread shows fish come for a look but often don't strike.

-

I printed wire spools.

Something not useful, but fun, I printed some wind turbines -- for me, this is the driven reason to buy a 3d printer.

I plan to print some stacking boxes to use corner spaces around furniture, but have not started yet.

-

on my workplace i use FDM Printed parts quite frequently for Workholding Jigs.

either on a CMM or on a Mill to get oddly shaped SLM Printed parts to behave.Printed stuff like a Door Dampener out of 60A TPU to prevent a door to slam shut during the summer months when i have a window open

also for a family member a guideblock for a Circular saw because of poor Manufacturing tolerances the included one had way to much play