@o_lampe ok thx,i will start with default 500 and then test and change from there...

Posts made by Stduplic

-

RE: DUEX5 Laser wiring and setings in g-codeposted in Laser Cutters

-

RE: DUEX5 Laser wiring and setings in g-codeposted in Laser Cutters

@o_lampe Thanks for clearing this out for me.

Do You think this part of the code is ok? or should I something change? -

DUEX5 Laser wiring and setings in g-codeposted in Laser Cutters

Hi,

I dont wont to make shorts on board and i didnt find what I am tryng make so i ask here for help and guidence...

I have custom made RRVcast 3 3d printer and recently i have bought Laser and will it to connect to printer so i can do engraving and small laser cutting eg.balsa2mm or making electronic boards ...

Laser is 5W 12 VDC 1.5-2Amp power request, with 5V PWM 5kHz

It has 3 pin for power and control it:

+12V

-Gnd

5V PWM 5kHz

My config is Duet 2 Wifi with Duex5 board on 24V supply.

First is it better to go with voltage regulator for droping down voltage from 24v to 12v ...it will be then GND shared with Duet/Duex...or to go with external 12 V supply...i have both and then do i need to connect GND with Duet/Duex for PWM to work or not?

If I can power it from external power supply and just connect PWM I would rather go that way, but if not posible i have also voltage droper.

Here is part of gcode for seting and controling laser...as stated from manual of Duex5 i can use PWM1-5 to control laser:

;;Controlling the laserM950 P4 C"duex.pwm1" Q5000 ; create Laser on pin Duex5_pwm1_E2_pwm pin

M452 C"duex.pwm1" R50 S0 F5000 ; set Laser mode, C"name" Pin name(s) and optional inversion!, Rnnn The value of the S parameter in G1 commands that corresponds to full laser power, default 255, Sn 1= laser power is sticky across G1 commands, 0 (default) = laser is off when executing G1 commands that have no S parameter, Fnnn The PWM frequency used to drive the laser - default is 500Hz

; M571 P"duex.pwm1" F200 S255Thank You for looking and help!

-

RE: Upgrading Nema17 motorsposted in Duet Hardware and wiring

Thank You all... I have ordered them... now just to wait that they arrive and then some printing again

-

RE: Upgrading Nema17 motorsposted in Duet Hardware and wiring

Thank You for sharing experience with me.

-

RE: Upgrading Nema17 motorsposted in Duet Hardware and wiring

First one is from stepper online oms manufacturer and second one I found on ooznest.co.uk and it is motech stepper manufacturer. I olready use 3 of the osm 1.8 degree 1.68amps 54g-cm2 rotor inertia and 0.44Nm holding torgue and I can say only that they are good motors quiet cool running (I set them to work at 1.4amp 16microstep with interpolation) so I am kind to pick again same manufacturer... There are reviews of them all 5star and people using it on delta but on ooznest they listed those 2 other models from Motech but I can't find any review but as they are specialising in selling 3d printers and parts I think they know what are they selling so I am in dilemma now...

Thanks for helping me..

-

RE: Upgrading Nema17 motorsposted in Duet Hardware and wiring

I so that post but what is bothering me is this inertia..how that impact perfomance?

-

RE: Upgrading Nema17 motorsposted in Duet Hardware and wiring

Yes I am using 24V 24Amps power supply

-

Upgrading Nema17 motorsposted in Duet Hardware and wiring

Hi,

I have delta printer with Duet3d WiFi and OMC Nema 17 1.8 degrees motors 17HS16-2004S1 (2 Amp/2 VDC/1.1 Ohm/2.6 mH@1kHz/0.45 Nm/54 g-cm2 rotor inertia)

I wont to upgrade to Nema 17 0.9 degrees motors to increase resolution/precision

I have narrowed the choice to this 3 motor:

OMS 17HM19-2004S1 (2 Amp/2.8 VDC/1.4 Ohm/3 mH@1kHz/0.46 Nm/82g-cm2 rotor inertia)

MT-1704HSM168A (1.68 Amp/2.8 VDC/1.65 Ohm/2.8 mH@1kHz/0.44 Nm/68 g-cm2 rotor inertia)

MT-1703HSM168A (1.68Amp/2.8 VDC/1.65 Ohm/3.6 mH@1kHz/0.35 Nm/54g-cm2 rotor inertia)

Price is allmost the same at all three motors.

Please help me chose what is going to be the best upgrade.Thank You all

Toni -

RE: Delta problem with X and Y movement while Z is OK?posted in General Discussion

Thank You !!!

Problem solved

I wont to express my gratitude towards You. Before I bought Duet3d I have read recensions about peoples experiences with different hardware and particularly important was to me support experience. I have post till now 2 questions that were a problem to me and You responded every time in a matter of hours and point me on right track to solve a problem. In this way, I wont to tell that I am more than satisfied buying Yours product and will for sure buy again. Thank You and don't change please, be like You are now.

Thank You !!!

Now on to my first print

-

RE: Delta problem with X and Y movement while Z is OK?posted in General Discussion

I think I got R completely wrong. I have measured R as a distance from the center of delta printer to the center of a vertical aluminum frame...

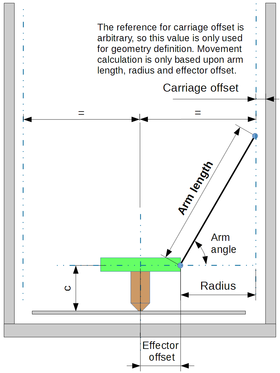

In this image that would be Effector offset + Radius + Carriage offset=224mm

Should I measure R like on this image is radius defined? image url)

image url)

Thank You -

RE: Delta problem with X and Y movement while Z is OK?posted in General Discussion

I have put B wrong that is sure plate is 265 or 275 not sure...I didnt know this can make isues...I had to check L and R latter and then will report back.

Thank You -

Delta problem with X and Y movement while Z is OK?posted in General Discussion

Hi,

I have finally finished building my homemade delta printer and for last couple days, I am playing with firmware configuration. Now I am stuck for two days and I don't know the solution. I am completely new to RepRap firmware and this is my first step into the world of 3d printing. I have Duet3d WiFi 1.04 running 2.0(RTOS) (2018-06-05b3)/WiFi server 1.21 and web interface 1.21.1.

I have made to the point where I have started to probe bed but then I have experienced problems. Delta does everything OK when I home printer, when I control fans, when I order to move in the Z axis up and down distance is OK, Z probe triggers and works ok.

But when I order simple move in X or Y lets say 100mm from web interface I get movement close to 180mm. Or when I try to execute automatic delta calibration head hits tower Z on the first probing point even if the radius is set to 100 in bed.g file.

Please help i don't know what is wrong with my configuration.

Motors are 1.8degree 200 steeps 2Amps, 16 tooth pinion with GT2 belt.

Link to my dropbox where are files (https://www.dropbox.com/sh/ohbd66v9emcts3f/AAAm0bKjPA2h4gs9FqV4dAs6a?dl=0)

Thank You... -

RE: Omron EE-SX 671/R optical sensors for Z probeposted in Duet Hardware and wiring

@dc42 said in Omron EE-SX 671/R optical sensors for Z probe:

That looks correct to me.

Thank You for helping me to be sure before wiring.

Just one more thing , is it ok to put diode 1N4001 at wire from sensor Out to Z_Probe_IN or it is not needed?

Thx,

Toni -

RE: Omron EE-SX 671/R optical sensors for Z probeposted in Duet Hardware and wiring

Can someone please check this scheme that I made and confirm is this wiring correct to use?

I have checked optical sensor Omron EE-SX671 with external supply at 5V and multimeter I have. There is no connection between sensor GND and OUT with power applied, but when blocking sensor diode light I have short between GND and OUT (approx 3-5 Ohm measuring between pins), thus OUT becomes GND and that routing to Z probe input.

Thanks

Toni -

RE: Omron EE-SX 671/R optical sensors for Z probeposted in Duet Hardware and wiring

Thank You for info.

I will try it -

Omron EE-SX 671/R optical sensors for Z probeposted in Duet Hardware and wiring

Re: [Duet Wifi with Bi-Directional Logic Level Converter](Optical End Stops)

Hi, I have recently bought Duet 3d WiFi V1.04 and have at home 5 pcs. Omron EE-SX 671(NPN) and 5 pcs. Omron EE-SX 671R(PNP) optical sensors. I have found this post and its clear how to connect them for end stops X,Y and Z for my delta printer. Question is can I use them for Z probe and if so how do I wire them?

Here is link with data shet for them

http://www.ia.omron.com/data_pdf/cat/ee-sx47_67_ds_e_13_2_csm483.pdf

Thank You, Toni