@mikeabuilder thanks for the great information and suggestions...

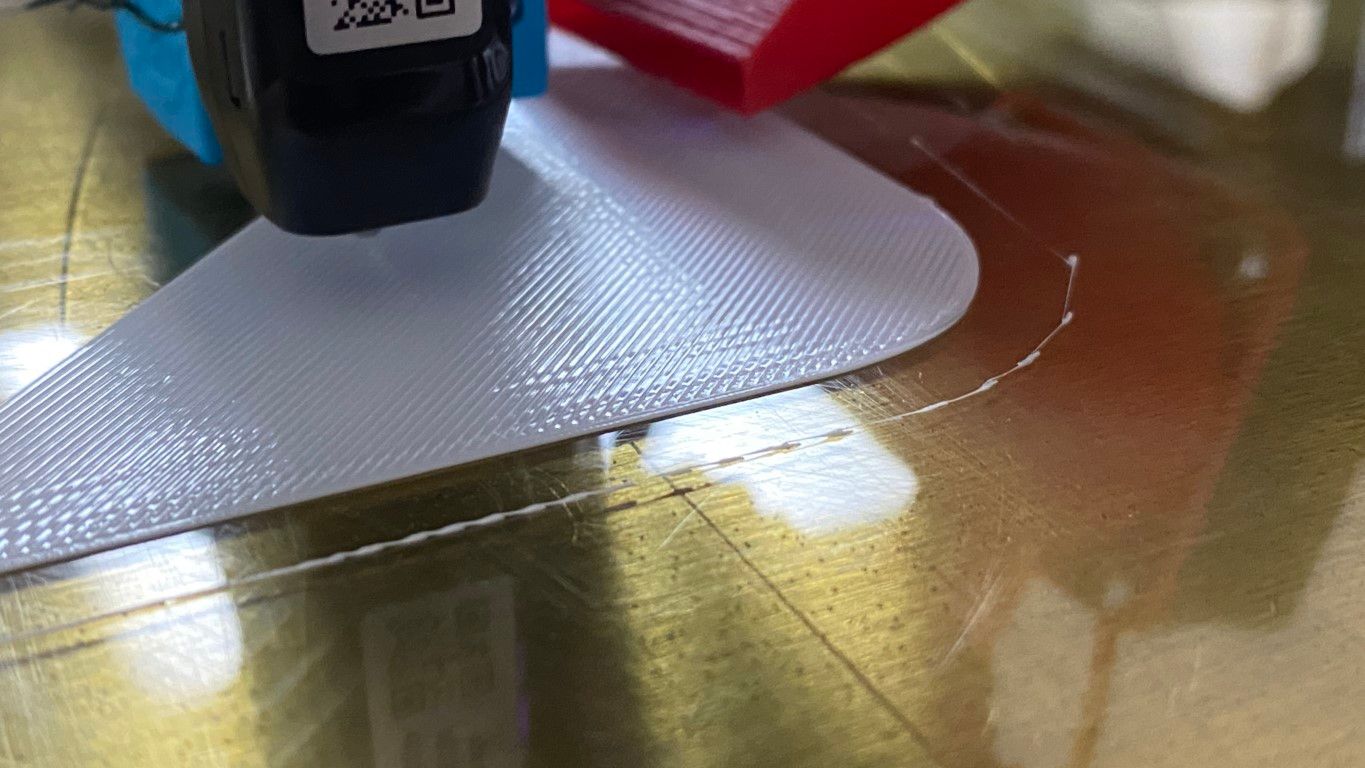

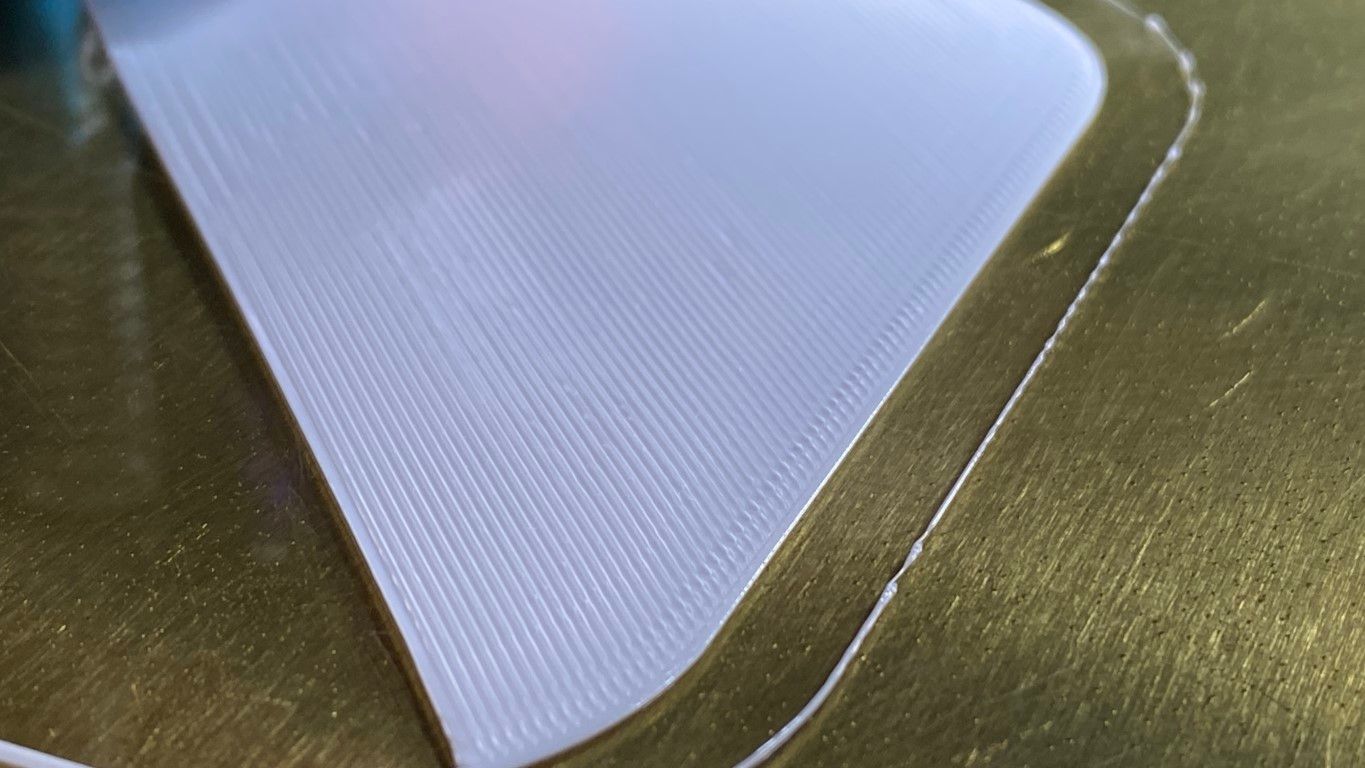

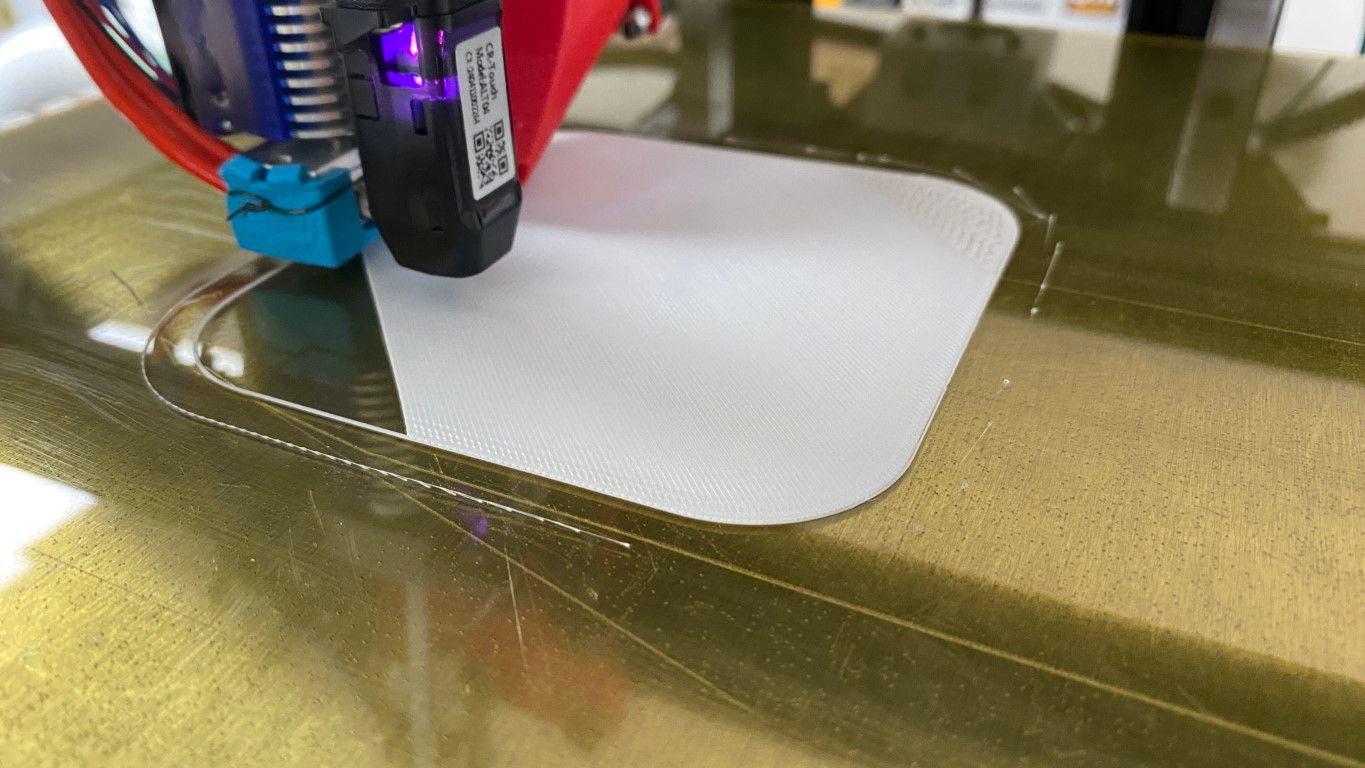

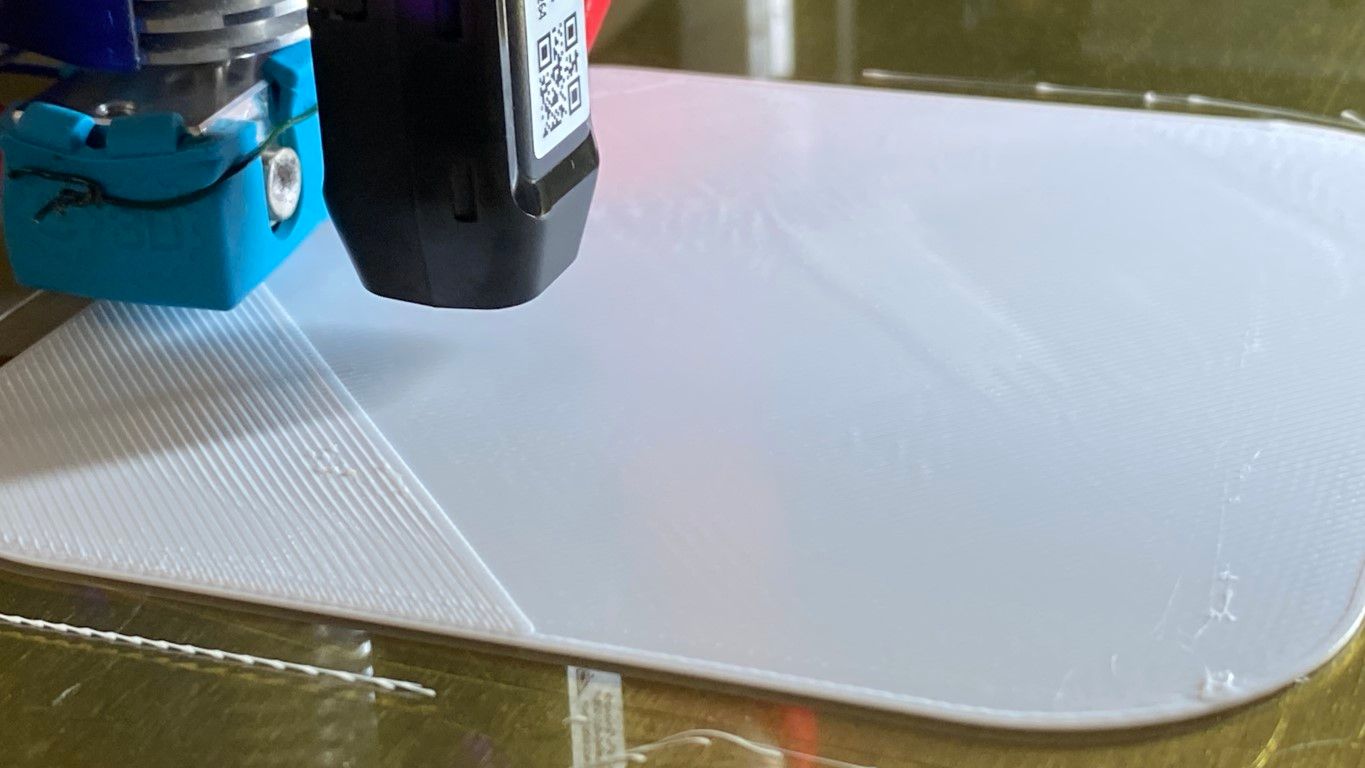

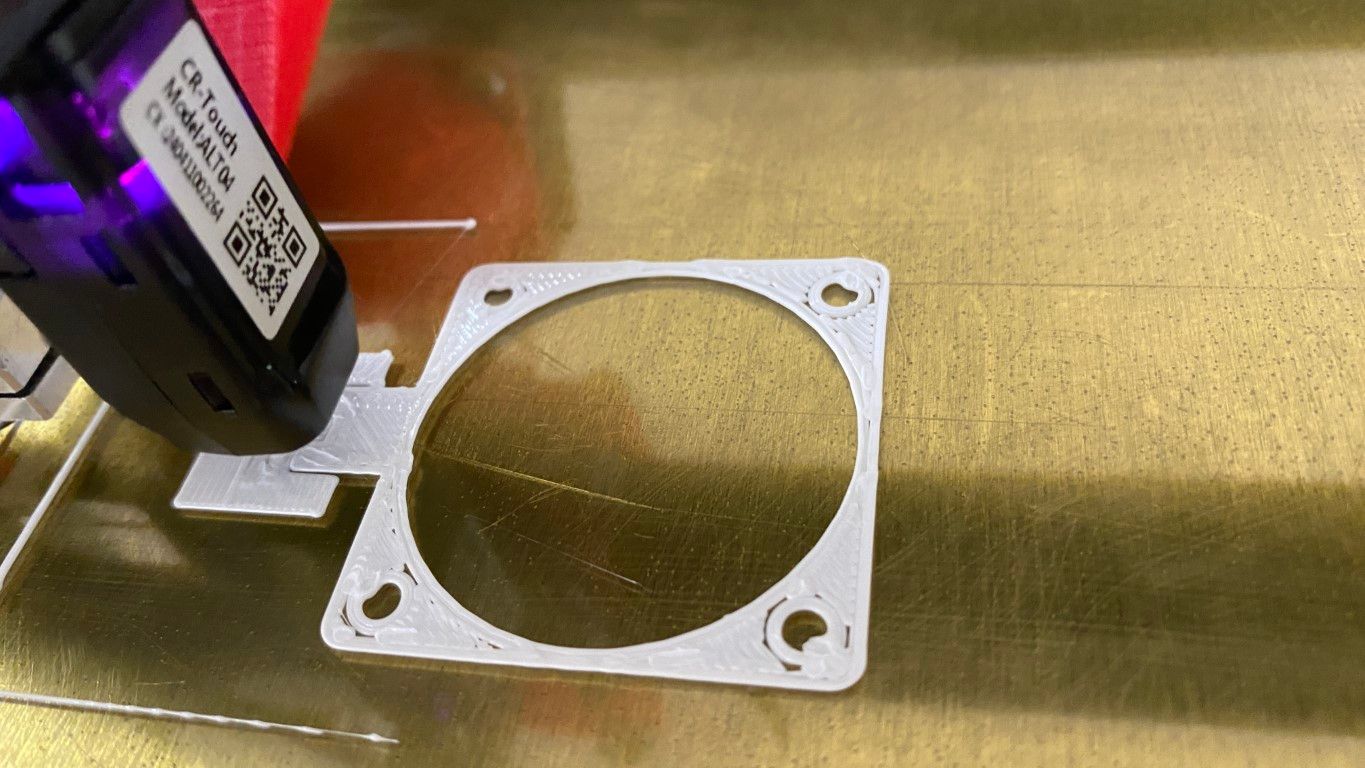

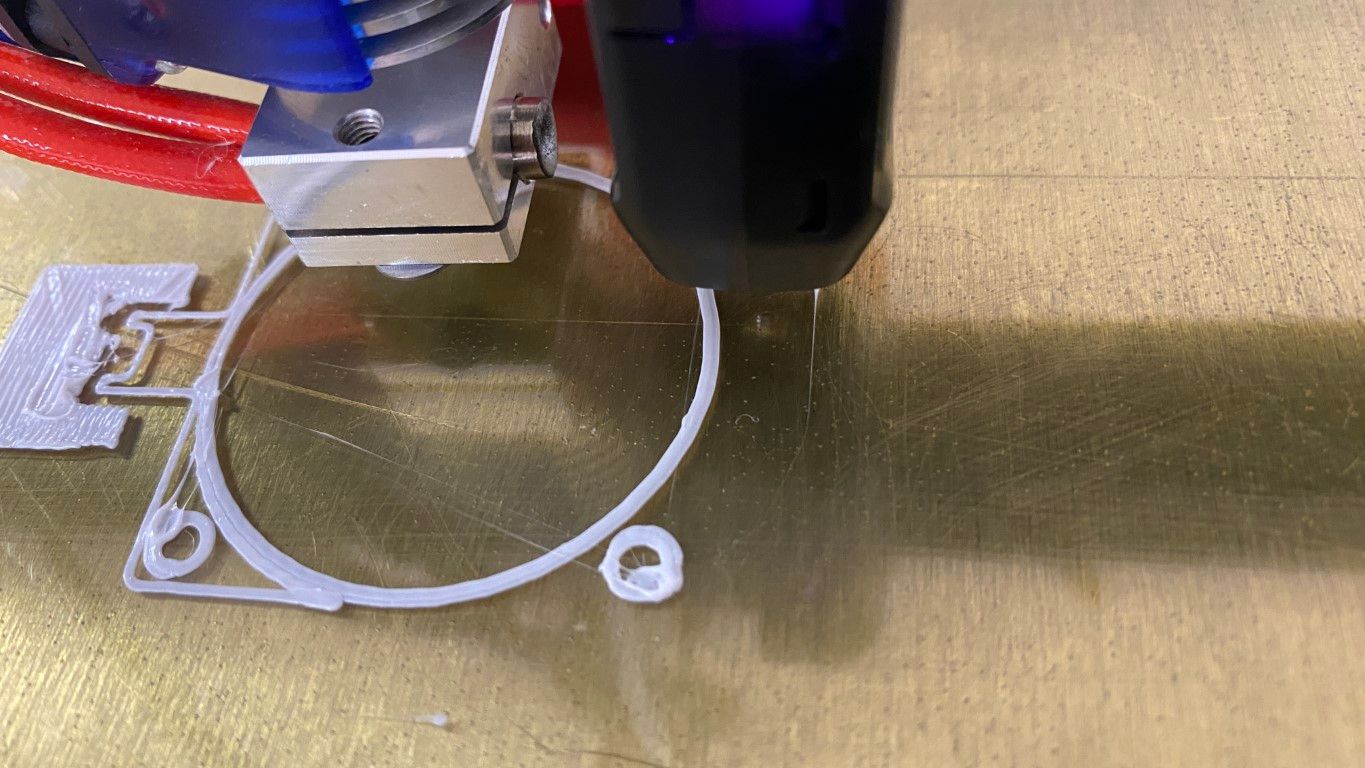

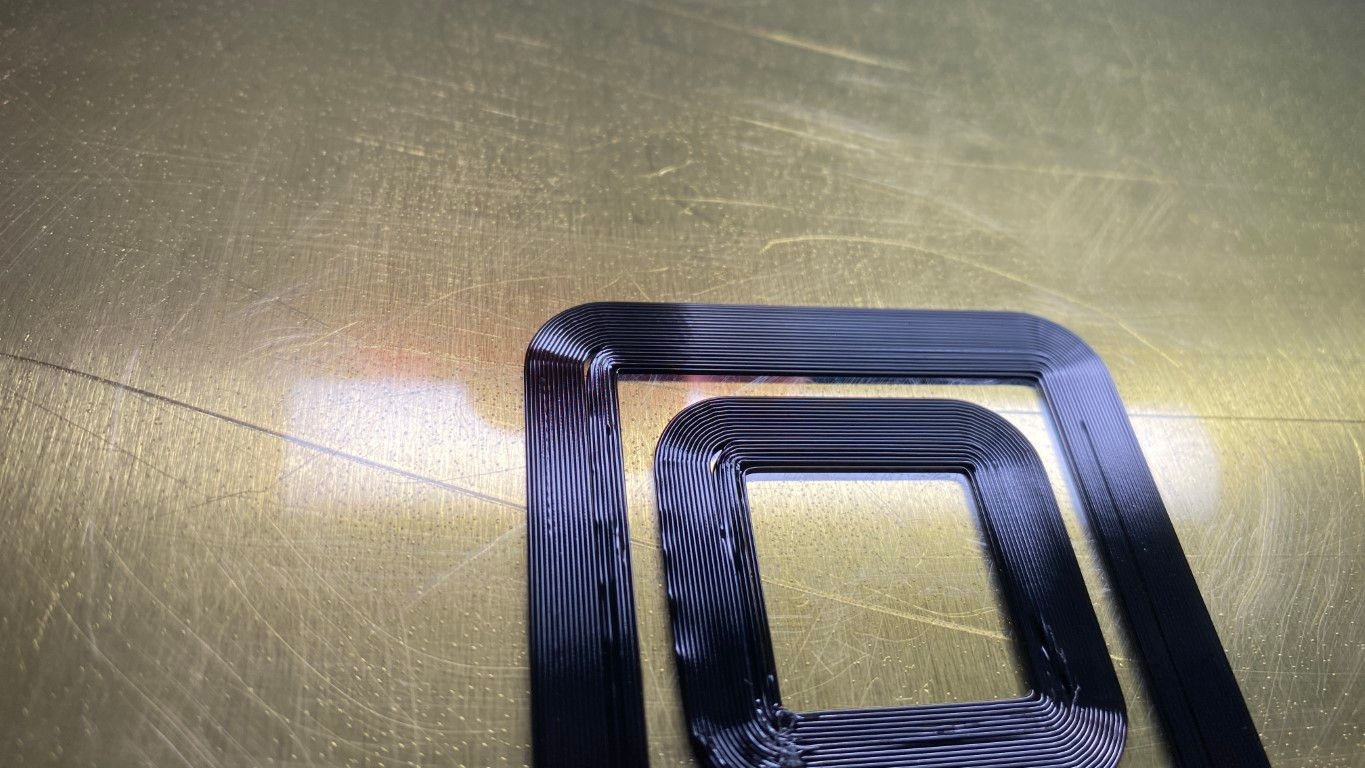

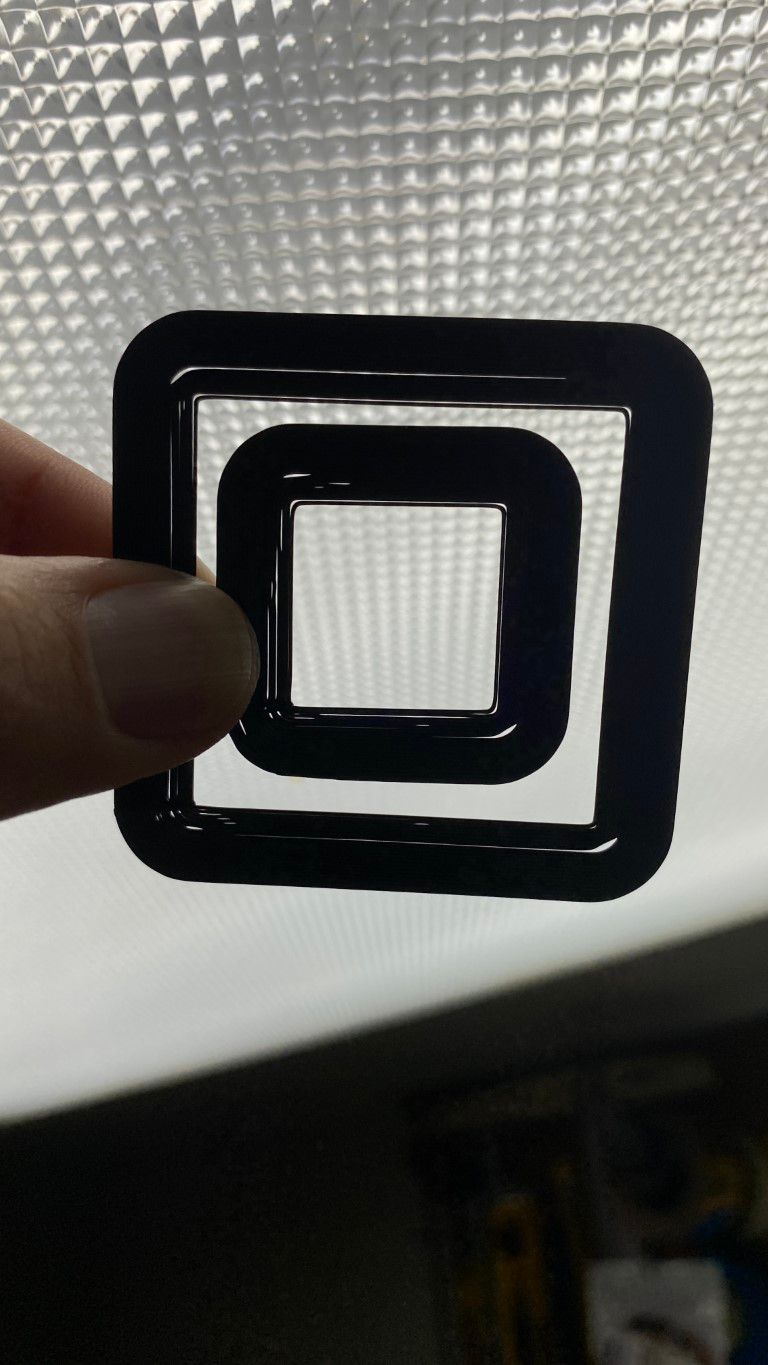

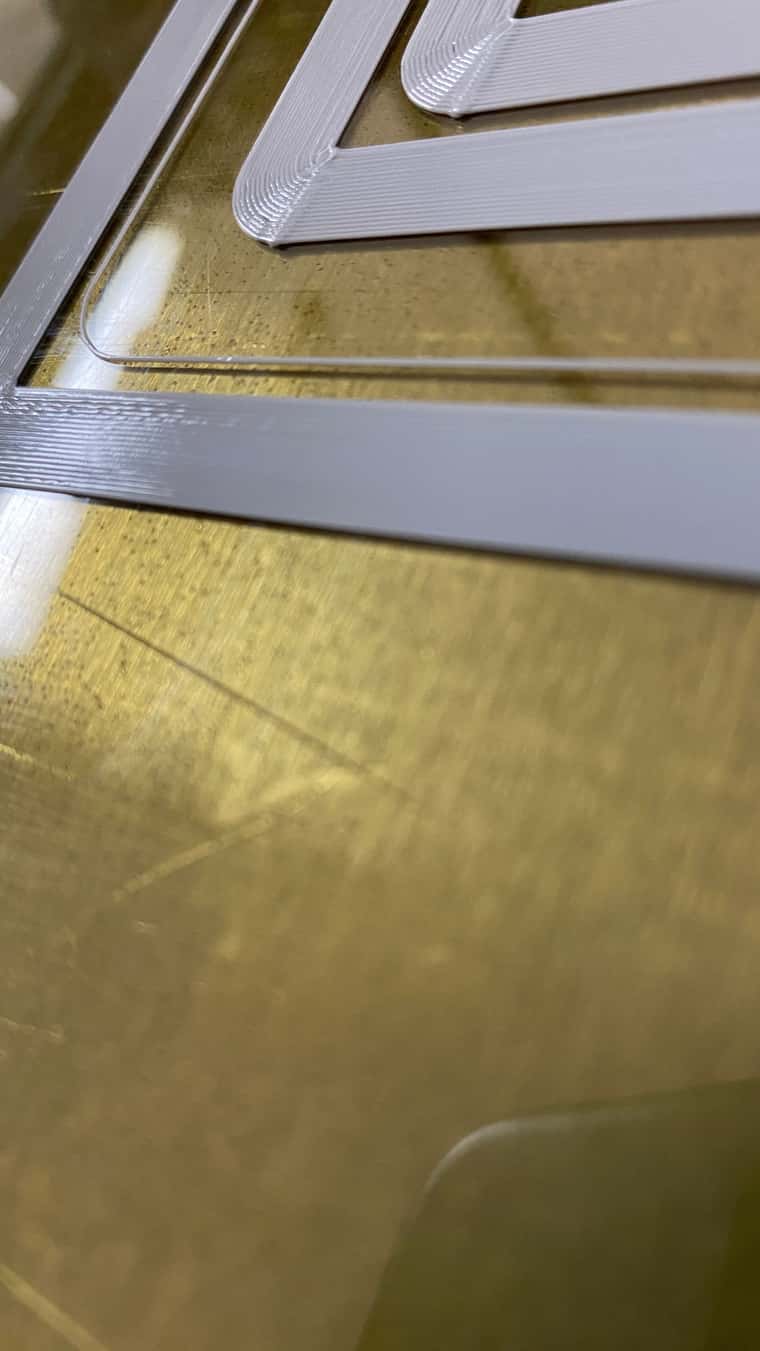

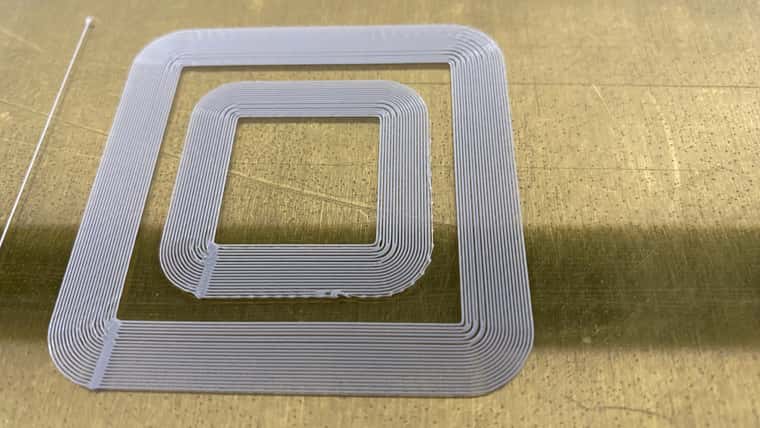

I'm surprised with the too close to the bed thought, I'm using a CR Touch and have gone through the setup more than once, I bought the tool to eliminate the guess work. The temperature comment I can understand, it looks too "liquid" to me also, I think the 1st and 2nd layers were printed at 210, as well as the detail part.

I'm guessing that I really need to print a Temperature tower, are there any good models out there, and do they adjust the temperature for you or do you have to adjust as it prints??

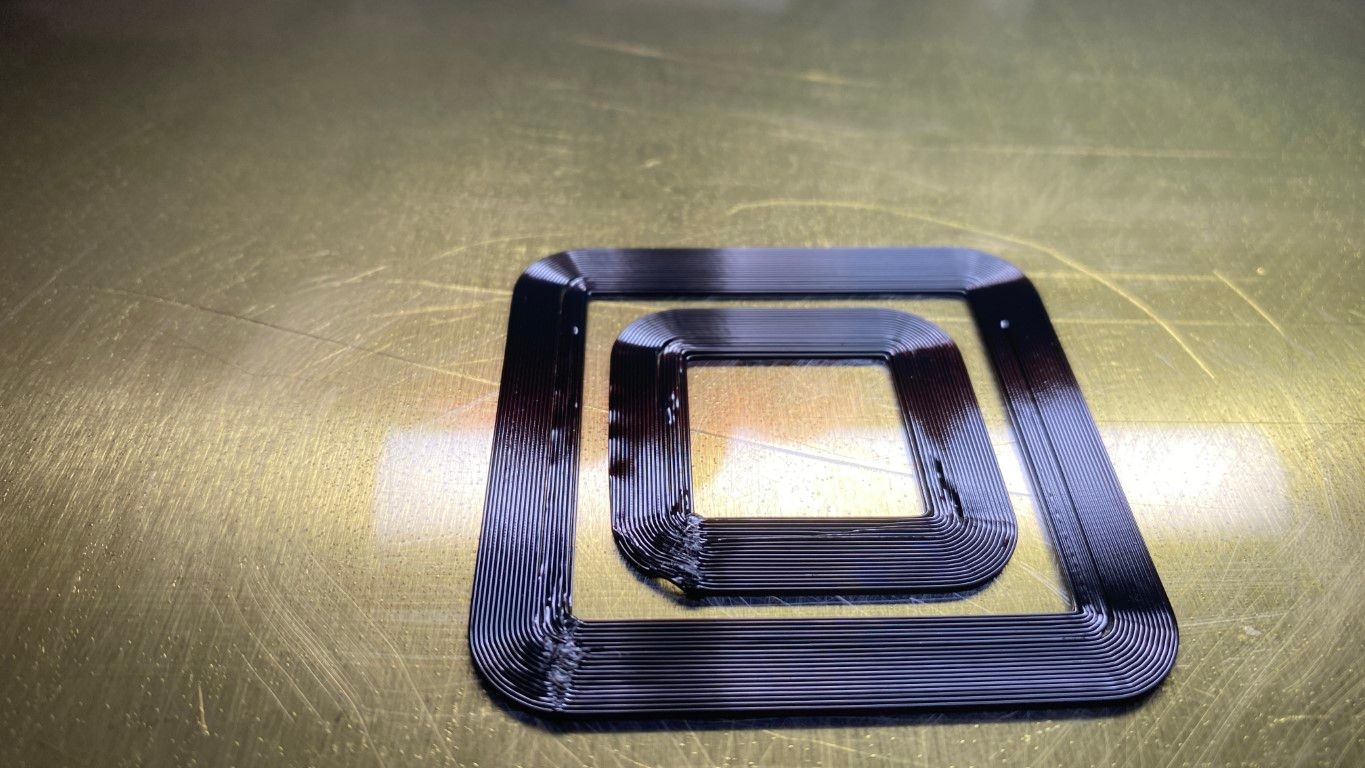

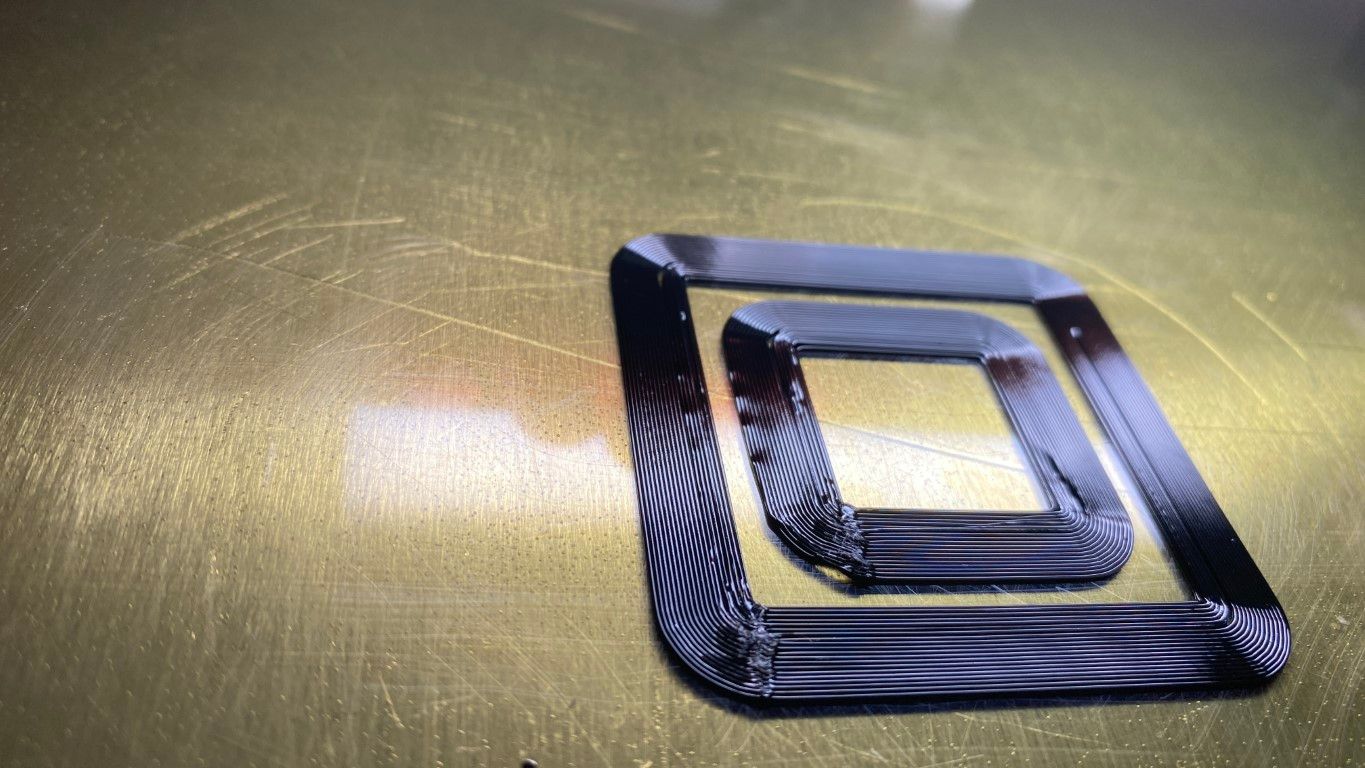

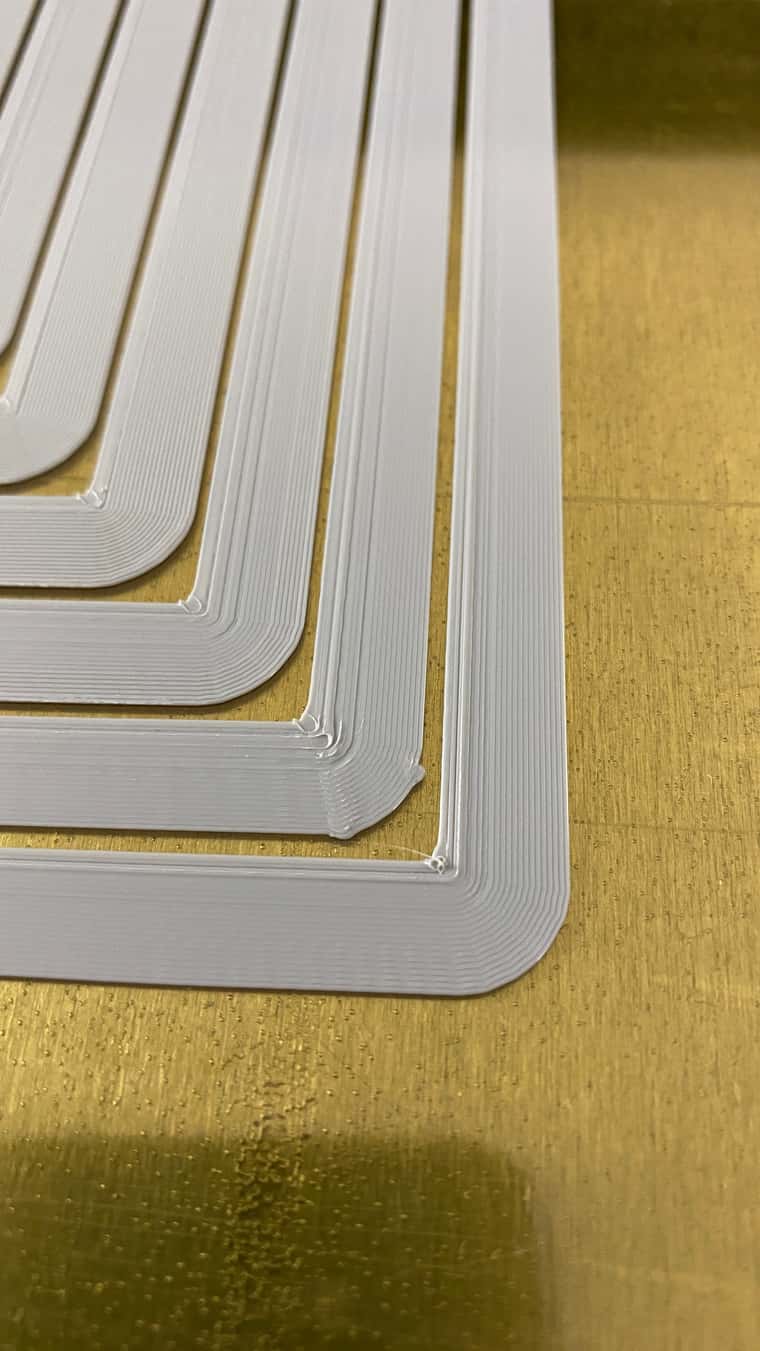

Today I was running some tests on a Test cube printing at 185 and raised the tip .010. Still some noise in the print and it still looks too hot. I'm wondering if there might be a problem with the thermistor cartridge and the temps are off?? I'm going to do some work here for sure.. I think a temp tower is probably my next best avenue.

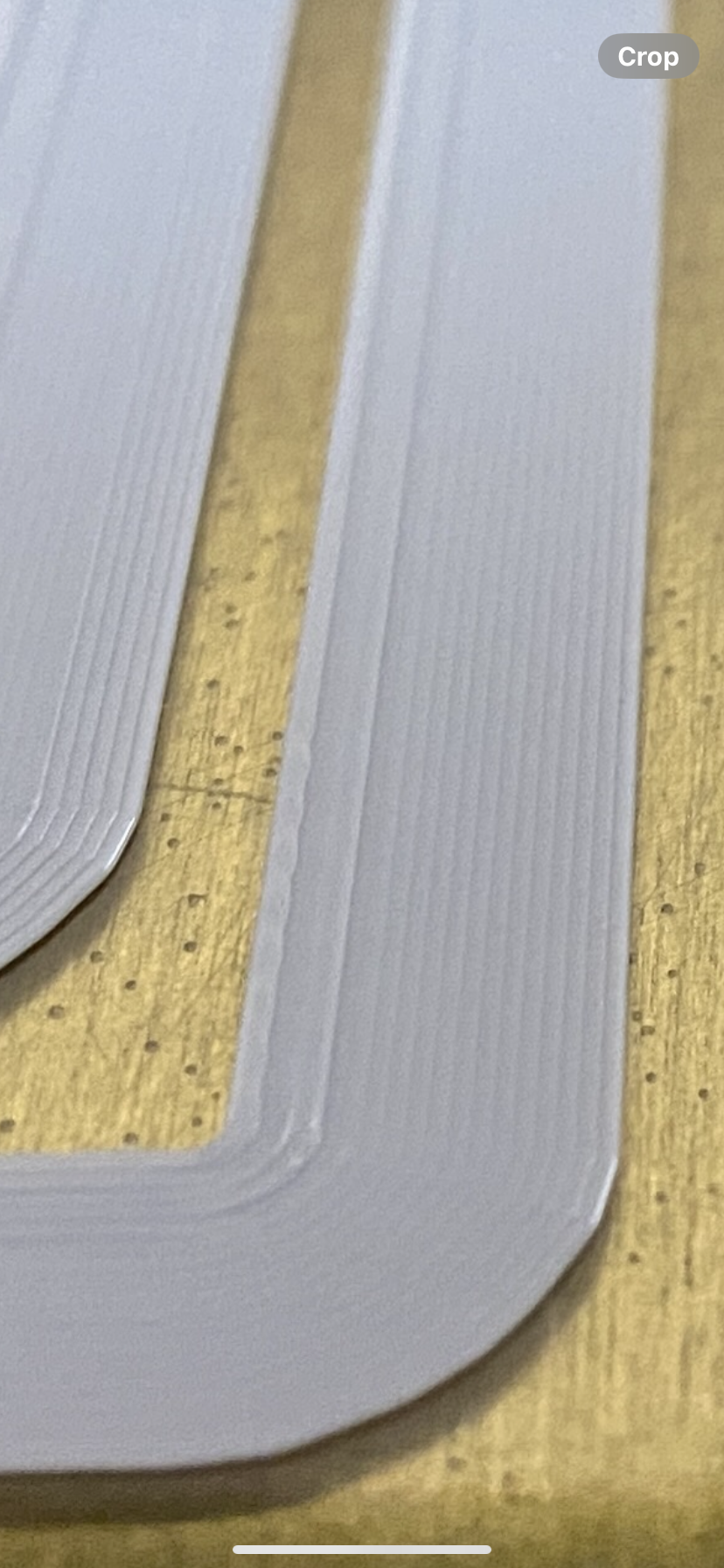

Over extrusion seems logical, but I've also gone through the extruder setup a couple of times. I've measured and marked the filament and fed the extruder 5mm from the control panel, and it seems to exactly feed 5mm. Its tough to work on all of the issues at once.. so I'm thinking a temp tower still might be my best starting point. I may also change back to the grey filament, its easier to see...

I took your advice on the sock, I cleaned the tip and trimmed the sock to expose the tip better and to eliminate the possibility of dragging if it were to occur.

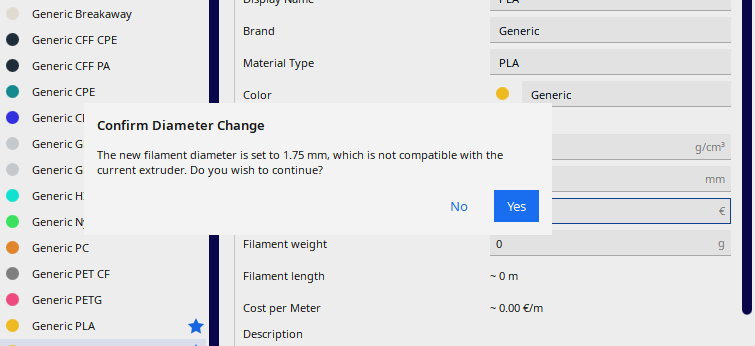

I've also switched to using Prusa as a slicer, I like the interface and like all of the other slicers there, there are a lot of options! I'm trying to stick to the basics as the moment. Layer hieght, retraction, temp, etc.