Round heater on a square heat bed?

-

My printer has a 310x310mm MK2A 3mm aluminum PCB bed with mounting holes positioned 35mm from the edges. I want to replace it with a 8mm (5/16") cast tooling plate and a 24V 350W silicon heater, preferably maintaining the existing dimensions.

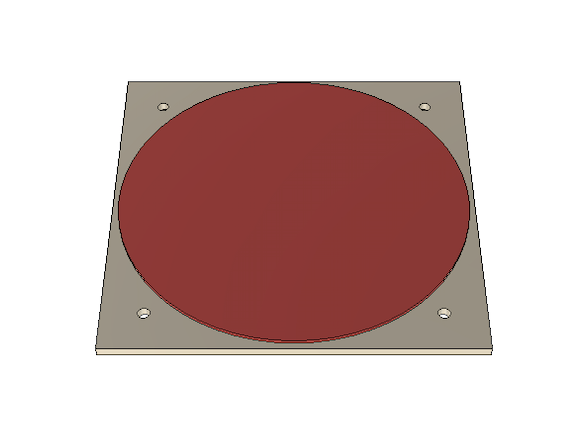

Is the arrangment in the picture below using 300mm round silicon heater reasonable or am I going to have inconsistent temperature at the edges? Anything else I should should be aware of?

(I am using 40W hotend heater and this power supply https://www.meanwell-web.com/en-gb/ac-dc-single-output-enclosed-power-supply-output-rsp--500--24 )

-

The metal that isn't directly over the heater will act as a heat sink. Temperature will drop off at the corners of the plate, so you may have trouble getting prints to stick away from the central circle that is heated.

Why wouldn't you use a square heater on a square plate? 300 x 300 mm heaters are readily available. It might be worth considering modification to the bed mounts to enable use of a square heater.

-

Keenovo might be able to make a heater with the necessary bolt holes so the heater reaches all the edges.

-

In my experience, AilRubber has been more economical than Keenvo and they dont stick it to you for custom work. They will glady make to your specs. I ordered TWO 350x350 800W was ~$80 USD shipped.

I ended up getting them to put a hole in the middle for my themristor and just kapton taped it .

Tip- if you want therms built in, get them to put in an extra as a spare and when you get it, write the type on the heater with a permanent marker.

YMMV. Good luck

-

You actually need more power in the corners to get the most even heat spread because, unlike the centre, they are not surrounded by heat on two sides. You also need a bit more power at the sides because they are not surrounded on one side.

So a circular heater has exactly the opposite power distribution that you want for a square bed. No heat in the corners, less at the sides and full in the middle.

-

I couldn't find any standard rectangular heater to fit, so I bought just the silicone insulated heater wire based off the resistance pr meter and laid out a snake like pattern with a length that would get me close to 0.4W/cm^2. Any temperature gradient was smaller than the thermal camera could pick up, and despite having the heater wire insulated in silicone, and bonded to the aluminium with very little surface area it got up to 100C in something like 6minutes.

I used a heatsink for the aluminium stock and laid the wire between the cooling ribs, so that gave me two points of contact to transfer the heat, and a little more surface for the silicone adhesive to adhere to compared to just a flat surface, but given that a pain it was to remove I would think a flat surface would be sufficient, the heatsink was just my cheapest option.

-

Here's the thermal performance of a 300 mm square, 750W Keenovo heater on a 300 mm square x 8mm thick bed plate, no thermal insulation added to underside of the plate, 0.7 mm of PEI on the top surface. As expected, the central area is hottest with a slight temperature drop around the edges. I can print ABS edge to edge on the plate.

-

@sinned6915 said in Round heater on a square heat bed?:

In my experience, AilRubber has been more economical than Keenvo and they dont stick it to you for custom work. They will glady make to your specs. I ordered TWO 350x350 800W was ~$80 USD shipped.

What is the process of ordering from AliRubber? What kind of information do you need to provide them? How long does it take?

I didn't find any information on the web site, just and email address so sent them and am waiting for response. I am thinking ordering one like this one https://www.aliexpress.com/item/32823941152.html but 24V, 350W.

BTW, in the instruction video of the Voron https://www.youtube.com/watch?v=8C4jtj0OuE4&t=420s , they seem to be ok with a heater that doesn't cover the entire 5/16" plate, this gave me the idea for the round heter.

-

@zapta

Besides using an oversized bed plate, they use 4 leveling screws, and bolt a cheapo no-spec TCO to the plate even though the heater is attached to the bed with adhesive that will let go after a year or two of temperature cycling.As my 8th grade science teacher once told me, "a good student is eternally skeptical". Question everything.

-

@mrehorstdmd, do you expect the silicon heater so stay stuck to the bottom of the bed only for a year or two? I always assumed it's 'permanent'.

BTW, I got a quote from Keenovo for a custom square heater. $73 including shipping. Looks very reasonable to me, so I placed the order.

-

@zapta They come with 468MP adhesive sheet on the heater. In my experience on two different printers, you have about 2 years before the adhesive starts to let go.

Keenovo says you should run a bead of high temperature silicone around the edge of the heater after sticking it down, and that may prevent letting go. I recently installed a new heater in my printer using high temperature silicone instead of 468MP. That won't let go.

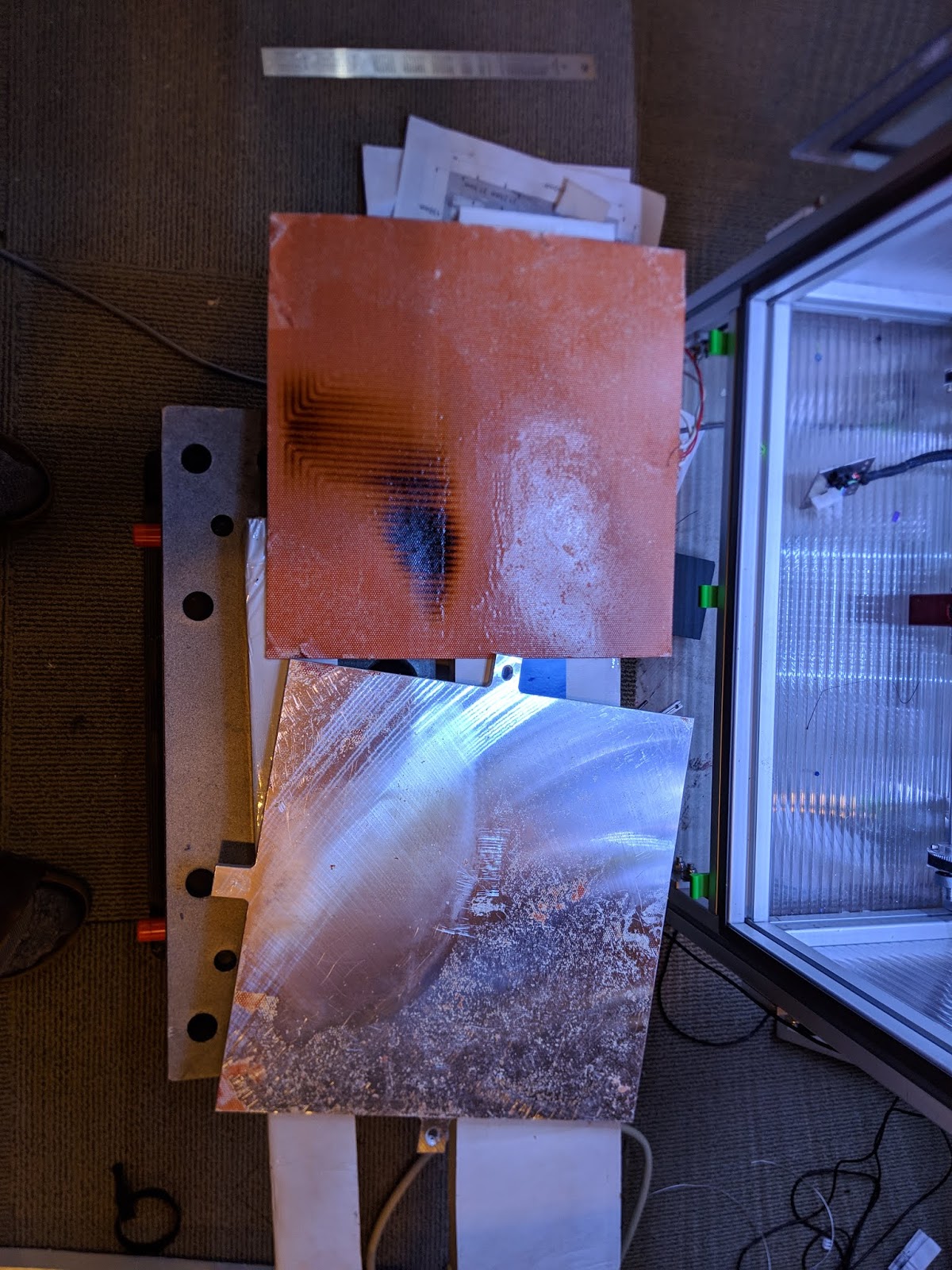

This is what it looks like when the heater starts coming off the bed:

The heater relies on the bed plate to act as a heatsink. A little air between the heater and the plate results in a great temperature rise that burns the silicone. That's why you want the TCO mounted on the heater and not the bed plate. If the heater comes off the plate, the TCO will stay with it and do its job.

-

@zapta -

sorry i did not reply sooner. this is the contact info I have for AliRubber.

Nicole Liu

AliRubbber

nicole@alirubber.com.cn

Cell/WhatsApp: +8613560469117

Normally I will reply you in 24 hours, if urgent and I didn't reply in time, please feel free to call me.I am sure that the one you ordered will be fine.

I would second mrehorstdmd's warning. Though I have not had that failure, I did remove my initial heater and found the center of the pad to look similar to the pic that he posted.

I fashioned my bed insulation in such a way to physically support the heater in the case of an adhesive failure as well.

I also intend to upgrade it by adding a thermal cutout- like these

https://www.ebay.com/itm/273570716627so that if it gets too hot, it will kill the power. MOSFETS's & SSR's usually fail with a closed contact failure, so its a physical failsafe in addition to the thermal runaway protection in the controller.

I don't print ABS, and usually run my bed at 50 -70C, so 105C seemed right for me.YMMV.

-

@sinned6915 I would recommend that instead of buying no spec/no cert parts, you go to digikey and buy a fully specced and certified part- try cantherm. They only cost about $1 each, and the data sheet will help you select the right part so you know what bed temperature will cause it to open.

-

@mrehorstdmd said in Round heater on a square heat bed?:

In my experience on two different printers, you have about 2 years before the adhesive starts to let go.

@mrehorstdmd, it looks bad in the picture. What bed temperature do you use (so far I used up to 70C for PETG and open frame so no chamber heat).

Also, what product did you use as the "high temperature silicone instead of 468MP" ?

-

@zapta Yopu don't have to operate the bed at a high temperature for it to burn like that. Any air gap between the heater and the bed plate will allow the heater to develop localized hot spots that can burn the silicone.

I operate the heater at 100C for printing ABS most of the time.I used some Permatex red high temperature silicone from an auto parts store.

-

@mrehorstdmd, is it more problematic with higher power density? Mine will be 350W for 305x305mm heater.

I searched again the internet and youtube for any mentioning for similar problems and couldn't find any. Also, the suggestions for installing a thermistor is typically on the Aluminum, not the heater itself, for example here https://www.youtube.com/watch?v=jp7ubpbaw-Q

Have you consider to have a writeup or video describing the problems you encountered and instructions how to choose and install a heater?

-

@zapta It may be more of an issue with higher powered heaters, but I wouldn't bet the farm on it.

The thermistor location is not really critical because the bed temperature isn't really critical. You set the bed temperature for whatever makes prints stick, and use PID to hold that temperature constant. The exact value doesn't matter.

If you really wanted to nit-pick, a thermistor measures the temperature at one point. The bed temperature isn't the same value everywhere, so which point is the "right" point? Thermistors mounted in the heater work fine (at least when using cast tooling plate beds).

TCO's should be mounted on the heater, not the bed plate. If the heater comes off the plate, the TCO won't do what it's supposed to do.

-

Got the custom Keenovo heater. Cost ~$80 shipped which is reasonable. Purchase was via email contact and took about 3 weeks to arrive. I didn't get any response from Ali Brothers.